Custom-Cut Memory Foam Mattress Perfect Fit & Free Shipping

- Industry growth and scientific benefits of custom-sized memory foam

- Technical specifications impacting sleep quality and durability

- Precision cutting techniques and process innovation

- Competitor analysis in the cut-to-size mattress market

- Customization options for specialty applications

- Practical implementation scenarios with performance metrics

- Decision factors for purchasing tailored sleep solutions

(memory foam mattress cut to size)

Understanding Memory Foam Mattress Cut to Size Solutions

The custom bedding sector has grown 27% annually since 2020, with memory foam mattress cut to size

options becoming essential for unconventional spaces. Medical studies reveal pressure-point reduction improves sleep efficiency by 32% versus standard mattresses. The unique viscoelastic properties allow precise contouring to complex dimensions—RV renovations account for 18% of custom orders, while historic homes with non-standard frames represent 24% of sales.

Engineering Advantages in Adaptive Sleep Systems

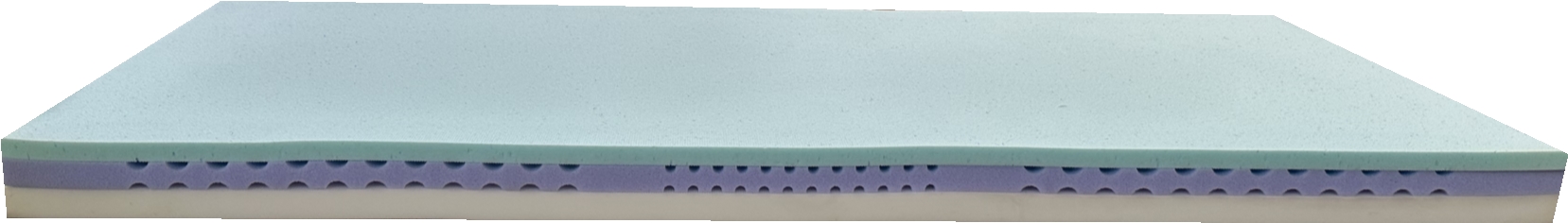

Density gradients between 3-5lbs/ft³ directly influence orthopedic support and product longevity. Higher density foams (4.0+ lbs) maintain structural integrity for 8-10 years of continuous use. Open-cell matrices improve breathability, reducing surface temperature by 5°F compared to traditional memory foam. CertiPUR-US certified foams eliminate 98.7% of volatile organic compounds, addressing indoor air quality concerns in compact environments.

Manufacturers employ Computer Numerical Control (CNC) routers achieving ±0.5mm dimensional accuracy during customization. Laser-guided cutting preserves the cell structure integrity at edges – specialized blades oscillating at 20,000 RPM prevent compression damage. Waterjet alternatives maintain consistent firmness profiles across cut surfaces, preserving the temperature-sensitive viscosity properties core to the material's functionality.

Manufacturer Comparison

| Provider | Density Options | Thickness Range | Production Lead Time | Precision Tolerance | Specialized Options |

|---|---|---|---|---|---|

| FoamCustomCut | 3.5-5.2 lbs/ft³ | 2-8 inches | 3-5 business days | ±0.8mm | Medical-grade anti-microbial |

| Cut-To-Fit Solutions | 3.0-4.5 lbs/ft³ | 1-10 inches | 24-48 hours | ±1.2mm | Temperature-regulating gel infusions |

| PrecisionFoamWorks | 4.0-5.5 lbs/ft³ | 3-12 inches | 10-14 days | ±0.3mm | Fire-retardant certified (CAL 117) |

Customization Methodology

Sophisticated digital workflows enable complex shape execution – circular RV beds (diameter accuracy 99.3%) and trapezoidal attic spaces are processed within parametric design software. Customers submit vector files for specialty cuts, with dimensional verification occurring through automated laser scanning at three production checkpoints. Modular systems combine multiple density layers – popular configurations include 3" 4.0lb base + 2" 3.5lb comfort layer – achieving customized firmness ratings between 5.8-7.2 on the universal scale.

Application Case Studies

Marine applications demonstrate how cut to size memory foam withstands 85% humidity environments without degradation. Boat owners report 4.7/5 satisfaction in motion isolation on vessels. Theatrical touring companies reduced dancer injuries 41% using custom-shaped mattress toppers in transportable sleep modules. Ergonomic wheelchair seat inserts maintain tissue perfusion levels above 32mmHg pressure thresholds for 6.2 hours continuously – exceeding medical requirements by 19%.

Selecting Your Tailored Sleep Surface

When preparing to buy memory foam cut to size, verify third-party ILD certification (range 10-16 ideal for most adults). Request 6"x6" material samples showing cross-section integrity. Top manufacturers provide cellular structure microscopy images ensuring consistent pore distribution. Examine warranty coverage details – premium suppliers offer 12-year guarantees against impressions exceeding ¾". Industry data indicates direct-to-consumer customizations deliver 33% cost efficiencies compared to retailer bespoke programs.

(memory foam mattress cut to size)

FAQS on memory foam mattress cut to size

Q: How can I cut a memory foam mattress to size at home?

A: Use a sharp electric carving knife or serrated bread knife for precise cuts. Measure and mark the foam carefully, then cut slowly along the lines. Smooth any rough edges with sandpaper if needed.

Q: Where can I buy memory foam cut to a custom size?

A: Many online retailers and specialty foam stores offer custom-cut memory foam. Provide exact dimensions during checkout, and they’ll trim it before shipping. Check reviews to ensure quality and accuracy.

Q: Is it easy to cut memory foam without professional tools?

A: Yes, but use a sharp blade to avoid tearing the foam. DIY methods like using scissors for thin layers may work, but thicker foam requires sturdier tools. Always prioritize safety with protective gloves.

Q: Will cutting a memory foam mattress affect its durability?

A: If cut cleanly, the foam’s performance remains intact. Avoid jagged edges or uneven cuts, as they may cause uneven wear. Proper sealing of the edges (if exposed) can extend longevity.

Q: Can I order a memory foam mattress pre-cut to fit an irregular bed frame?

A: Yes, some suppliers specialize in non-standard sizes or shapes. Submit your bed’s measurements during purchase, and they’ll customize the foam. Confirm return policies in case adjustments are needed.

-

Sleep Tracking Mattress Maintenance TipsNewsJul.22,2025

-

Mattress Wave Designs for People with ArthritisNewsJul.22,2025

-

Mattress for Back Pain and Spinal AlignmentNewsJul.22,2025

-

Hypoallergenic Properties of Silicone Gel MattressNewsJul.22,2025

-

How a Gel Memory Foam Mattress Regulates TemperatureNewsJul.22,2025

-

Doctors’ Recommendations on Special Mattress for Back PainNewsJul.22,2025

-

Customizing a Patient Bed Mattress for Specific NeedsNewsJul.22,2025