Waterproof Medical Mattress: High Quality Hospital Bed Solutions

The Crucial Role of Advanced Medical Mattresses in Modern Healthcare

In the dynamic landscape of modern healthcare, the role of specialized support surfaces, particularly the medical mattress, has become increasingly critical. These aren't merely bedding; they are sophisticated medical devices engineered to enhance patient recovery, prevent pressure injuries, and optimize comfort in various clinical settings. The global market for hospital bedding, including specialized mattresses, is experiencing robust growth, driven by an aging population, rising incidence of chronic diseases, and a heightened focus on patient safety and quality of care. Innovations in material science and design are continuously transforming how hospitals approach patient support, moving beyond basic comfort to advanced therapeutic solutions.

From intensive care units (ICUs) to long-term care facilities, the demand for high-performance mattresses is escalating. Facilities are actively seeking solutions that offer superior pressure redistribution, infection control, and durability. This includes a particular emphasis on products like the waterproof mattress, which is essential for maintaining hygiene and extending product life in demanding healthcare environments. The shift towards evidence-based practice further mandates the adoption of mattresses that have proven clinical efficacy in preventing conditions such as pressure ulcers, significantly reducing healthcare costs associated with treatment and extended hospital stays.

Understanding the technical parameters, manufacturing precision, and application specificities of a specialized hospital bed mattress is vital for healthcare procurement specialists and clinicians alike. The right choice can profoundly impact patient outcomes and operational efficiency.

Unpacking the Manufacturing Excellence of Medical Mattresses

The production of a high-quality medical mattress is a meticulously controlled process, blending advanced material science with precision engineering. Unlike conventional mattresses, these specialized products undergo rigorous manufacturing steps to meet stringent medical standards.

Materials Selection and Preparation:

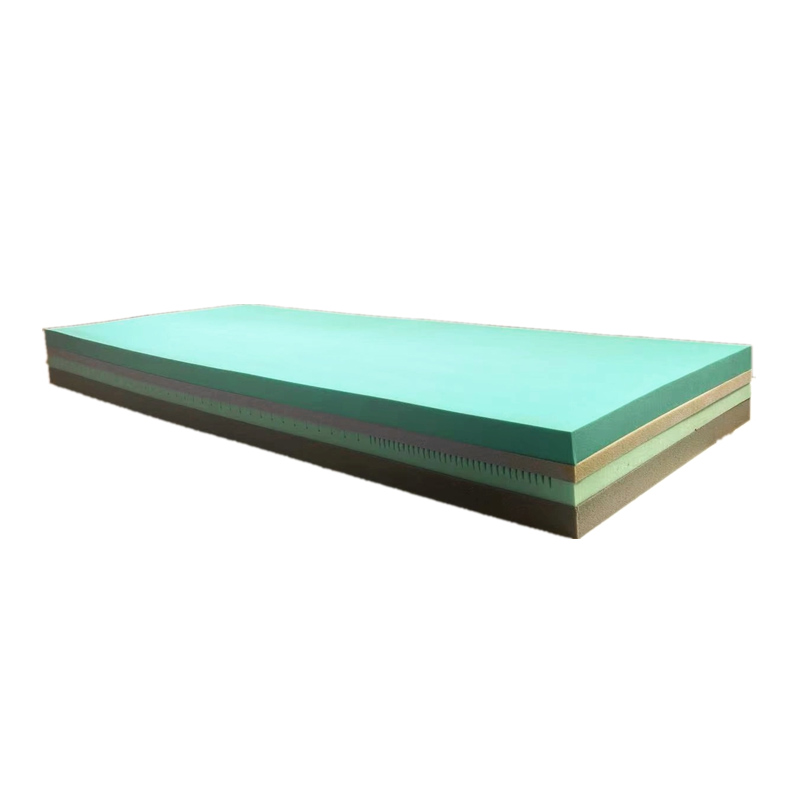

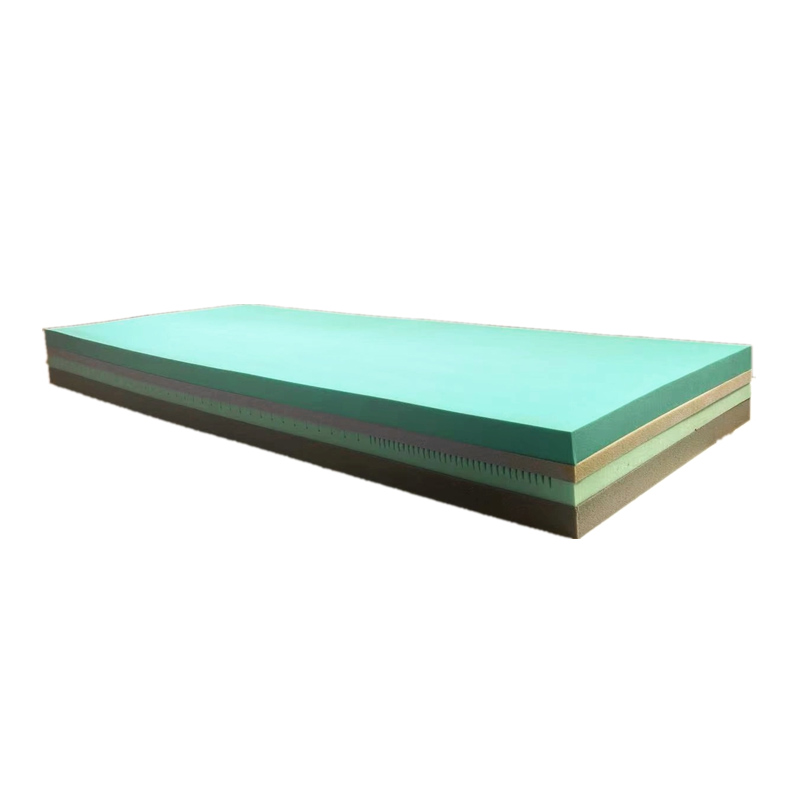

The foundation lies in selecting medical-grade materials. For products like the ICU Nursing Silicon Mattress, this typically involves high-resilience foam, visco-elastic (memory) foam, and often a silicon gel layer for superior pressure distribution and cooling. The cover material is critical, usually made from advanced polyurethane (PU) or thermoplastic polyurethane (TPU) films, which are inherently waterproof mattress materials, breathable, and easy to clean. All materials must be biocompatible, non-toxic, and flame retardant, complying with international safety standards.

Core Construction and Layering:

The core assembly involves precision cutting of foam layers using CNC technology to ensure exact dimensions and density profiles. Different foam densities are strategically layered to create zones of varying firmness, optimizing pressure redistribution and preventing bottoming out. For silicon mattresses, a specialized molding process is often employed to create the unique gel patterns that conform to the patient's body, reducing shear and friction forces. Adhesives used are medical-grade, non-VOC (volatile organic compound) ensuring patient safety and environmental compliance.

Cover Fabrication and Sealing:

The outer cover, often designed as a waterproof hospital bed mattress cover, is fabricated using high-frequency welding or heat-sealing techniques to create fluid-proof seams. This critical step ensures that no liquids can penetrate the core, preventing bacterial growth and simplifying disinfection protocols. Zippers, if present, are typically covered with a flap to maintain fluid resistance. This meticulous sealing process is paramount for infection control in clinical environments, reflecting why many facilities choose to buy waterproof mattress options.

Quality Control and Testing:

Every hospital bed mattress undergoes stringent quality checks throughout its manufacturing journey. This includes material inspection, dimensional verification, and performance testing. Key tests include pressure mapping to assess redistribution capabilities, durability testing for long-term use (simulating patient movement over thousands of cycles), flame retardancy testing (e.g., California Technical Bulletin 117), and fluid penetration resistance. Compliance with international standards such as ISO 13485 for medical device quality management and FDA regulations is non-negotiable for any reputable hospital bed mattress factory. This ensures each product offers superior performance and a long service life of typically 5-7 years, even under intensive hospital use, providing significant advantages in patient safety and operational cost-efficiency across various healthcare settings.

Technical Parameters & Performance Benchmarks for Medical Mattresses

Selecting the right medical mattress requires a deep understanding of its technical specifications. These parameters dictate the mattress’s effectiveness in pressure ulcer prevention, patient comfort, and durability. Below is a table detailing critical parameters relevant to high-performance medical mattresses, including our ICU Nursing Silicon Mattress.

These detailed specifications allow healthcare providers to make informed decisions when they buy hospital bed mattress solutions, ensuring the selected product aligns with clinical needs and institutional standards. A reputable hospital bed mattress factory will always provide transparent data on these key performance indicators.

Application Scenarios & Performance Advantages of Advanced Medical Mattresses

The versatility and specialized design of modern medical mattress solutions make them indispensable across a wide spectrum of healthcare environments. Each application demands specific features and performance attributes, which advanced mattresses are engineered to provide.

Intensive Care Units (ICU) & Critical Care:

In the ICU, patients often have limited mobility and are highly susceptible to pressure injuries. Mattresses here, like our ICU Nursing Silicon Mattress, must offer dynamic pressure redistribution, often through advanced static foam layers with integrated silicon or gel elements. Key advantages include superior shear reduction, microclimate management (reducing heat and moisture build-up), and the ability to accommodate rapid changes in patient condition or position. The easy-to-clean waterproof mattress surface is crucial for infection control in these high-acuity settings.

General Hospital Wards & Post-Surgical Recovery:

For general ward use and post-surgical recovery, the emphasis is on consistent comfort and effective pressure ulcer prevention for patients with varying mobility levels. A high quality waterproof mattress provides a stable, comfortable surface that supports natural movement while mitigating pressure points. The durability of these mattresses ensures long-term performance under continuous use, making them a cost-effective choice for hospital procurement.

Long-Term Care Facilities & Nursing Homes:

In long-term care settings, patients often reside for extended periods, necessitating mattresses that offer exceptional comfort and prolonged pressure injury prevention. The easy maintenance and waterproof mattress service capabilities of these products are highly valued, simplifying sanitation protocols and ensuring a hygienic environment. Products optimized for these settings contribute significantly to residents' quality of life and reduce caregiver burden.

Home Healthcare:

As healthcare increasingly shifts to the home, the need for reliable hospital bed mattress solutions for home use grows. Patients and caregivers buy hospital bed mattress options that are easy to manage, durable, and provide therapeutic benefits comparable to those found in clinical settings. The compact design and light weight of some models make them ideal for residential environments, ensuring continuity of care and comfort.

Across all these applications, the core advantages remain consistent: superior pressure ulcer prevention (reducing incidence by up to 50% in some studies), enhanced patient comfort leading to improved sleep and recovery, significant infection control benefits due to waterproof mattress covers, and extended product lifespan, which translates to reduced replacement costs for healthcare institutions.

Choosing Your Partner: Why Xinmattress Stands Out as a Hospital Bed Mattress Factory

When healthcare institutions look to buy hospital bed mattress solutions, the choice of manufacturer is as critical as the product itself. Xinmattress, as a leading hospital bed mattress factory, distinguishes itself through a blend of innovative product design, stringent quality control, and comprehensive customer support.

Product Focus: ICU Nursing Silicon Mattress

Our flagship ICU Nursing Silicon Mattress exemplifies our commitment to advanced patient care. This mattress integrates a multi-layered foam core with a specialized silicon gel overlay, precisely engineered for superior pressure redistribution and thermal regulation. The seamless, fluid-proof, and breathable PU cover ensures excellent infection control and durability, making it a high quality waterproof mattress ideal for critical care environments where hygiene and patient safety are paramount. It's designed to minimize shear forces and facilitate microclimate management, directly contributing to the prevention of pressure injuries even in highly vulnerable patients.

Customization and Flexible Solutions:

Recognizing that every healthcare facility has unique requirements, Xinmattress offers extensive customization options. Whether you need specific dimensions, different foam densities, specialized cover materials, or unique anti-slip base designs, our team can tailor solutions to meet your precise needs. This flexibility is particularly valuable for hospitals or nursing homes looking to outfit entire units or standardize their china hospital bed mattress inventory. We work closely with clients from concept to delivery, ensuring the final product integrates seamlessly into existing infrastructure and clinical protocols.

Commitment to Quality & Certifications:

As an ISO 13485 certified manufacturer, Xinmattress adheres to the highest international standards for medical device quality management. Our products are CE certified for the European market and comply with relevant FDA guidelines for the US market. Each batch undergoes rigorous testing, including durability, pressure mapping, and flammability tests, ensuring consistent performance and reliability. This commitment to quality assures clients they are investing in a durable and clinically effective medical mattress.

Competitive Value for Procurement:

While quality is paramount, cost-effectiveness is also a major consideration for healthcare procurement. Xinmattress offers competitive pricing for our medical mattress solutions, including options for a cheap hospital bed mattress without compromising essential medical integrity. Our manufacturing efficiency and robust supply chain allow us to deliver superior products at an attractive price point, offering excellent value for institutions looking to buy hospital bed mattress in bulk or single units. Our strong reputation in the china hospital bed mattress market speaks volumes about our balance of quality and affordability.

Ensuring Trust and Reliability: Our Commitment to Service

At Xinmattress, trust is built not just on the quality of our medical mattress products, but also on the reliability of our services. We understand that for healthcare institutions, a seamless procurement process, timely delivery, and responsive support are as vital as the product itself.

Quality Assurance and Warranty:

Every hospital bed mattress from our factory comes with a comprehensive warranty, typically ranging from 3 to 5 years, covering manufacturing defects and material integrity under normal use. This commitment underscores our confidence in the durability and performance of our products, providing peace of mind for institutions making significant investments in patient care equipment. Our ISO 13485 certification means every stage, from raw material sourcing to final product inspection, adheres to strict medical device quality standards.

Delivery and Logistics:

We operate an efficient global logistics network to ensure timely delivery of your medical mattress orders, whether you're sourcing from our china hospital bed mattress factory or need expedited shipment to a specific region. Standard lead times for common mattress models are typically 3-4 weeks, with expedited options available for urgent requirements. We work closely with reliable shipping partners to ensure products arrive safely and on schedule, minimizing any disruption to your operations.

Dedicated Customer Support:

Our dedicated customer support team is available to assist with product selection, technical inquiries, order tracking, and any post-purchase support needs. We offer extensive waterproof mattress service advice, including best practices for cleaning and maintenance to maximize product lifespan and performance. Client satisfaction is our priority, and we strive to build long-term partnerships based on reliability and excellent service.

Frequently Asked Questions (FAQ) About Medical Mattresses

Q1: What is the lifespan of a typical medical mattress?

A1: The lifespan of a medical mattress depends on its type, usage intensity, and maintenance. High-quality foam or silicon mattresses like the ICU Nursing Silicon Mattress are designed for durability, often lasting 5 to 7 years in clinical environments with proper care. Factors like consistent cleaning and adherence to weight limits extend their functional life.

Q2: Are all hospital bed mattress products truly waterproof?

A2: Not all are fully waterproof, but a high-quality hospital bed mattress for clinical use should have a fluid-resistant or waterproof mattress cover. Our products feature advanced PU/TPU covers with sealed seams, ensuring fluids cannot penetrate the core. This is crucial for infection control and maintaining hygiene in healthcare settings.

Q3: How do I choose between different types of medical mattress for my facility?

A3: The choice depends on patient acuity, risk of pressure injury, and budget. For high-risk or ICU patients, advanced multi-layered foam or silicon mattresses are recommended. For general wards, a good quality foam medical mattress might suffice. Consider factors like pressure redistribution, ease of cleaning, weight capacity, and flammability standards. Our experts can assist you in making an informed decision.

Q4: What certifications should I look for when I buy hospital bed mattress solutions?

A4: Look for certifications like ISO 13485 (Medical Devices Quality Management System), CE marking (for European market), and compliance with local fire safety standards (e.g., Cal TB 117 for US). These indicate that the hospital bed mattress factory adheres to strict quality and safety protocols.

Q5: Can I get customized medical mattress solutions from Xinmattress?

A5: Absolutely. We specialize in providing customized medical mattress solutions to meet specific client requirements. This includes variations in size, foam type, density, cover materials, and special features. Contact our sales team with your specifications, and we'll work with you to develop the ideal solution.

Conclusion: Investing in Superior Patient Outcomes

The strategic selection of a medical mattress is a critical decision for any healthcare provider aiming to elevate patient care standards while managing operational costs effectively. As demonstrated, advanced mattresses are not merely passive supports but active therapeutic devices integral to preventing pressure injuries, promoting comfort, and ensuring a hygienic environment. From the rigorous manufacturing processes in a specialized hospital bed mattress factory to the intricate technical parameters that dictate performance, every aspect contributes to the overall efficacy and safety of the product.

Xinmattress stands as a trusted partner, offering not only cutting-edge products like the ICU Nursing Silicon Mattress but also unparalleled expertise, customization capabilities, and steadfast customer support. For institutions looking to buy hospital bed mattress solutions that embody reliability, innovation, and clinical effectiveness, we provide the assurance of a high quality waterproof mattress that meets the demanding needs of modern healthcare. Investing in the right medical mattress is an investment in superior patient outcomes and sustainable healthcare operations.

References

- National Pressure Ulcer Advisory Panel (NPUAP), European Pressure Ulcer Advisory Panel (EPUAP) and Pan Pacific Pressure Injury Alliance (PPPIA). Prevention and Treatment of Pressure Ulcers: Clinical Practice Guideline. 3rd Edition. 2014.

- Agency for Healthcare Research and Quality (AHRQ). Preventing Pressure Ulcers in Hospitals: A Toolkit for Improving Quality of Care. 2014.

- ISO 13485: Medical devices — Quality management systems — Requirements for regulatory purposes. International Organization for Standardization. Current Edition.

- California Bureau of Home Furnishings and Thermal Insulation. Technical Bulletin 117-2013: Requirements, Test Procedure and Apparatus for Testing the Smolder Resistance of Materials Used in Upholstered Furniture.

- Krasner D, Rodeheaver GT, Sibbald RG. Chronic Wound Care: A Clinical Source Book for Healthcare Professionals. HMP Communications. 5th Edition. 2012.

The Crucial Role of Advanced Medical Mattresses in Modern Healthcare

In the dynamic landscape of modern healthcare, the role of specialized support surfaces, particularly the medical mattress, has become increasingly critical. These aren't merely bedding; they are sophisticated medical devices engineered to enhance patient recovery, prevent pressure injuries, and optimize comfort in various clinical settings. The global market for hospital bedding, including specialized mattresses, is experiencing robust growth, driven by an aging population, rising incidence of chronic diseases, and a heightened focus on patient safety and quality of care. Innovations in material science and design are continuously transforming how hospitals approach patient support, moving beyond basic comfort to advanced therapeutic solutions.

From intensive care units (ICUs) to long-term care facilities, the demand for high-performance mattresses is escalating. Facilities are actively seeking solutions that offer superior pressure redistribution, infection control, and durability. This includes a particular emphasis on products like the waterproof mattress, which is essential for maintaining hygiene and extending product life in demanding healthcare environments. The shift towards evidence-based practice further mandates the adoption of mattresses that have proven clinical efficacy in preventing conditions such as pressure ulcers, significantly reducing healthcare costs associated with treatment and extended hospital stays.

Understanding the technical parameters, manufacturing precision, and application specificities of a specialized hospital bed mattress is vital for healthcare procurement specialists and clinicians alike. The right choice can profoundly impact patient outcomes and operational efficiency.

Unpacking the Manufacturing Excellence of Medical Mattresses

The production of a high-quality medical mattress is a meticulously controlled process, blending advanced material science with precision engineering. Unlike conventional mattresses, these specialized products undergo rigorous manufacturing steps to meet stringent medical standards.

Materials Selection and Preparation:

The foundation lies in selecting medical-grade materials. For products like the ICU Nursing Silicon Mattress, this typically involves high-resilience foam, visco-elastic (memory) foam, and often a silicon gel layer for superior pressure distribution and cooling. The cover material is critical, usually made from advanced polyurethane (PU) or thermoplastic polyurethane (TPU) films, which are inherently waterproof mattress materials, breathable, and easy to clean. All materials must be biocompatible, non-toxic, and flame retardant, complying with international safety standards.

Core Construction and Layering:

The core assembly involves precision cutting of foam layers using CNC technology to ensure exact dimensions and density profiles. Different foam densities are strategically layered to create zones of varying firmness, optimizing pressure redistribution and preventing bottoming out. For silicon mattresses, a specialized molding process is often employed to create the unique gel patterns that conform to the patient's body, reducing shear and friction forces. Adhesives used are medical-grade, non-VOC (volatile organic compound) ensuring patient safety and environmental compliance.

Cover Fabrication and Sealing:

The outer cover, often designed as a waterproof hospital bed mattress cover, is fabricated using high-frequency welding or heat-sealing techniques to create fluid-proof seams. This critical step ensures that no liquids can penetrate the core, preventing bacterial growth and simplifying disinfection protocols. Zippers, if present, are typically covered with a flap to maintain fluid resistance. This meticulous sealing process is paramount for infection control in clinical environments, reflecting why many facilities choose to buy waterproof mattress options.

Quality Control and Testing:

Every hospital bed mattress undergoes stringent quality checks throughout its manufacturing journey. This includes material inspection, dimensional verification, and performance testing. Key tests include pressure mapping to assess redistribution capabilities, durability testing for long-term use (simulating patient movement over thousands of cycles), flame retardancy testing (e.g., California Technical Bulletin 117), and fluid penetration resistance. Compliance with international standards such as ISO 13485 for medical device quality management and FDA regulations is non-negotiable for any reputable hospital bed mattress factory. This ensures each product offers superior performance and a long service life of typically 5-7 years, even under intensive hospital use, providing significant advantages in patient safety and operational cost-efficiency across various healthcare settings.

Technical Parameters & Performance Benchmarks for Medical Mattresses

Selecting the right medical mattress requires a deep understanding of its technical specifications. These parameters dictate the mattress’s effectiveness in pressure ulcer prevention, patient comfort, and durability. Below is a table detailing critical parameters relevant to high-performance medical mattresses, including our ICU Nursing Silicon Mattress.

These detailed specifications allow healthcare providers to make informed decisions when they buy hospital bed mattress solutions, ensuring the selected product aligns with clinical needs and institutional standards. A reputable hospital bed mattress factory will always provide transparent data on these key performance indicators.

Application Scenarios & Performance Advantages of Advanced Medical Mattresses

The versatility and specialized design of modern medical mattress solutions make them indispensable across a wide spectrum of healthcare environments. Each application demands specific features and performance attributes, which advanced mattresses are engineered to provide.

Intensive Care Units (ICU) & Critical Care:

In the ICU, patients often have limited mobility and are highly susceptible to pressure injuries. Mattresses here, like our ICU Nursing Silicon Mattress, must offer dynamic pressure redistribution, often through advanced static foam layers with integrated silicon or gel elements. Key advantages include superior shear reduction, microclimate management (reducing heat and moisture build-up), and the ability to accommodate rapid changes in patient condition or position. The easy-to-clean waterproof mattress surface is crucial for infection control in these high-acuity settings.

General Hospital Wards & Post-Surgical Recovery:

For general ward use and post-surgical recovery, the emphasis is on consistent comfort and effective pressure ulcer prevention for patients with varying mobility levels. A high quality waterproof mattress provides a stable, comfortable surface that supports natural movement while mitigating pressure points. The durability of these mattresses ensures long-term performance under continuous use, making them a cost-effective choice for hospital procurement.

Long-Term Care Facilities & Nursing Homes:

In long-term care settings, patients often reside for extended periods, necessitating mattresses that offer exceptional comfort and prolonged pressure injury prevention. The easy maintenance and waterproof mattress service capabilities of these products are highly valued, simplifying sanitation protocols and ensuring a hygienic environment. Products optimized for these settings contribute significantly to residents' quality of life and reduce caregiver burden.

Home Healthcare:

As healthcare increasingly shifts to the home, the need for reliable hospital bed mattress solutions for home use grows. Patients and caregivers buy hospital bed mattress options that are easy to manage, durable, and provide therapeutic benefits comparable to those found in clinical settings. The compact design and light weight of some models make them ideal for residential environments, ensuring continuity of care and comfort.

Choosing Your Partner: Why Xinmattress Stands Out as a Hospital Bed Mattress Factory

When healthcare institutions look to buy hospital bed mattress solutions, the choice of manufacturer is as critical as the product itself. Xinmattress, as a leading hospital bed mattress factory, distinguishes itself through a blend of innovative product design, stringent quality control, and comprehensive customer support.

Product Focus: ICU Nursing Silicon Mattress

Our flagship ICU Nursing Silicon Mattress exemplifies our commitment to advanced patient care. This mattress integrates a multi-layered foam core with a specialized silicon gel overlay, precisely engineered for superior pressure redistribution and thermal regulation. The seamless, fluid-proof, and breathable PU cover ensures excellent infection control and durability, making it a high quality waterproof mattress ideal for critical care environments where hygiene and patient safety are paramount. It's designed to minimize shear forces and facilitate microclimate management, directly contributing to the prevention of pressure injuries even in highly vulnerable patients.

Customization and Flexible Solutions:

Recognizing that every healthcare facility has unique requirements, Xinmattress offers extensive customization options. Whether you need specific dimensions, different foam densities, specialized cover materials, or unique anti-slip base designs, our team can tailor solutions to meet your precise needs. This flexibility is particularly valuable for hospitals or nursing homes looking to outfit entire units or standardize their china hospital bed mattress inventory. We work closely with clients from concept to delivery, ensuring the final product integrates seamlessly into existing infrastructure and clinical protocols.

Commitment to Quality & Certifications:

As an ISO 13485 certified manufacturer, Xinmattress adheres to the highest international standards for medical device quality management. Our products are CE certified for the European market and comply with relevant FDA guidelines for the US market. Each batch undergoes rigorous testing, including durability, pressure mapping, and flammability tests, ensuring consistent performance and reliability. This commitment to quality assures clients they are investing in a durable and clinically effective medical mattress.

Competitive Value for Procurement:

While quality is paramount, cost-effectiveness is also a major consideration for healthcare procurement. Xinmattress offers competitive pricing for our medical mattress solutions, including options for a cheap hospital bed mattress without compromising essential medical integrity. Our manufacturing efficiency and robust supply chain allow us to deliver superior products at an attractive price point, offering excellent value for institutions looking to buy hospital bed mattress in bulk or single units. Our strong reputation in the china hospital bed mattress market speaks volumes about our balance of quality and affordability.

Ensuring Trust and Reliability: Our Commitment to Service

At Xinmattress, trust is built not just on the quality of our medical mattress products, but also on the reliability of our services. We understand that for healthcare institutions, a seamless procurement process, timely delivery, and responsive support are as vital as the product itself.

Quality Assurance and Warranty:

Every hospital bed mattress from our factory comes with a comprehensive warranty, typically ranging from 3 to 5 years, covering manufacturing defects and material integrity under normal use. This commitment underscores our confidence in the durability and performance of our products, providing peace of mind for institutions making significant investments in patient care equipment. Our ISO 13485 certification means every stage, from raw material sourcing to final product inspection, adheres to strict medical device quality standards.

Delivery and Logistics:

We operate an efficient global logistics network to ensure timely delivery of your medical mattress orders, whether you're sourcing from our china hospital bed mattress factory or need expedited shipment to a specific region. Standard lead times for common mattress models are typically 3-4 weeks, with expedited options available for urgent requirements. We work closely with reliable shipping partners to ensure products arrive safely and on schedule, minimizing any disruption to your operations.

Dedicated Customer Support:

Our dedicated customer support team is available to assist with product selection, technical inquiries, order tracking, and any post-purchase support needs. We offer extensive waterproof mattress service advice, including best practices for cleaning and maintenance to maximize product lifespan and performance. Client satisfaction is our priority, and we strive to build long-term partnerships based on reliability and excellent service.

Frequently Asked Questions (FAQ) About Medical Mattresses

Q1: What is the lifespan of a typical medical mattress?

A1: The lifespan of a medical mattress depends on its type, usage intensity, and maintenance. High-quality foam or silicon mattresses like the ICU Nursing Silicon Mattress are designed for durability, often lasting 5 to 7 years in clinical environments with proper care. Factors like consistent cleaning and adherence to weight limits extend their functional life.

Q2: Are all hospital bed mattress products truly waterproof?

A2: Not all are fully waterproof, but a high-quality hospital bed mattress for clinical use should have a fluid-resistant or waterproof mattress cover. Our products feature advanced PU/TPU covers with sealed seams, ensuring fluids cannot penetrate the core. This is crucial for infection control and maintaining hygiene in healthcare settings.

Q3: How do I choose between different types of medical mattress for my facility?

A3: The choice depends on patient acuity, risk of pressure injury, and budget. For high-risk or ICU patients, advanced multi-layered foam or silicon mattresses are recommended. For general wards, a good quality foam medical mattress might suffice. Consider factors like pressure redistribution, ease of cleaning, weight capacity, and flammability standards. Our experts can assist you in making an informed decision.

Q4: What certifications should I look for when I buy hospital bed mattress solutions?

A4: Look for certifications like ISO 13485 (Medical Devices Quality Management System), CE marking (for European market), and compliance with local fire safety standards (e.g., Cal TB 117 for US). These indicate that the hospital bed mattress factory adheres to strict quality and safety protocols.

Q5: Can I get customized medical mattress solutions from Xinmattress?

A5: Absolutely. We specialize in providing customized medical mattress solutions to meet specific client requirements. This includes variations in size, foam type, density, cover materials, and special features. Contact our sales team with your specifications, and we'll work with you to develop the ideal solution.

Conclusion: Investing in Superior Patient Outcomes

The strategic selection of a medical mattress is a critical decision for any healthcare provider aiming to elevate patient care standards while managing operational costs effectively. As demonstrated, advanced mattresses are not merely passive supports but active therapeutic devices integral to preventing pressure injuries, promoting comfort, and ensuring a hygienic environment. From the rigorous manufacturing processes in a specialized hospital bed mattress factory to the intricate technical parameters that dictate performance, every aspect contributes to the overall efficacy and safety of the product.

Xinmattress stands as a trusted partner, offering not only cutting-edge products like the ICU Nursing Silicon Mattress but also unparalleled expertise, customization capabilities, and steadfast customer support. For institutions looking to buy hospital bed mattress solutions that embody reliability, innovation, and clinical effectiveness, we provide the assurance of a high quality waterproof mattress that meets the demanding needs of modern healthcare. Investing in the right medical mattress is an investment in superior patient outcomes and sustainable healthcare operations.

References

- National Pressure Ulcer Advisory Panel (NPUAP), European Pressure Ulcer Advisory Panel (EPUAP) and Pan Pacific Pressure Injury Alliance (PPPIA). Prevention and Treatment of Pressure Ulcers: Clinical Practice Guideline. 3rd Edition. 2014.

- Agency for Healthcare Research and Quality (AHRQ). Preventing Pressure Ulcers in Hospitals: A Toolkit for Improving Quality of Care. 2014.

- ISO 13485: Medical devices — Quality management systems — Requirements for regulatory purposes. International Organization for Standardization. Current Edition.

- California Bureau of Home Furnishings and Thermal Insulation. Technical Bulletin 117-2013: Requirements, Test Procedure and Apparatus for Testing the Smolder Resistance of Materials Used in Upholstered Furniture.

- Krasner D, Rodeheaver GT, Sibbald RG. Chronic Wound Care: A Clinical Source Book for Healthcare Professionals. HMP Communications. 5th Edition. 2012.

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025

-

Innovative Wave Mattresses for Ultimate ComfortNewsAug.08,2025

-

High-Quality Mattresses for Hospital BedsNewsAug.08,2025

-

High-Quality Mattresses for Every NeedNewsAug.08,2025

-

Healthcare Foam Mattress: Sleep Better, Heal FasterNewsAug.08,2025

-

Cube Mattress for Daily ComfortNewsAug.08,2025

-

How Hospital Mattress Choices Directly Impact Patient Comfort and CareNewsAug.05,2025