Enhance Medical Care: Best Gel Mattress for Bedsores Relief

Elevating Patient Outcomes: The Crucial Role of Advanced Pressure-Relief Solutions in Modern medical care

In contemporary healthcare, the prevention and management of pressure injuries (also known as bedsores or decubitus ulcers) represent a significant challenge, impacting patient quality of life, increasing healthcare costs, and extending hospital stays. Advanced pressure-relief solutions are fundamental to effective patient management, providing foundational support for comprehensive medical care strategies. The evolution of the medical mattress, particularly the gel mattress, has been pivotal in addressing these complex issues, offering superior pressure distribution and microclimate management to mitigate the risks associated with prolonged immobility. This detailed exploration delves into the technical intricacies, application benefits, and strategic considerations for integrating high-performance pressure-relief mattresses into modern healthcare systems.

Industry Trends in Pressure Relief Medical Care Technology

The landscape of pressure injury prevention is continuously evolving, driven by advancements in material science, sensor technology, and patient-centric design principles. Key trends indicate a shift towards proactive and personalized solutions:

- Smart Mattress Systems: Integration of embedded sensors for continuous pressure mapping, patient movement monitoring, and real-time feedback to caregivers, optimizing repositioning schedules and preventing adverse events.

- Advanced Material Composites: Development of multi-layered systems combining viscoelastic foams, air cells, and advanced gel technologies to achieve optimal pressure redistribution, shear reduction, and temperature regulation.

- Infection Control & Hygiene: Focus on easily cleanable, impermeable, and antimicrobial cover materials that withstand rigorous disinfection protocols, crucial for maintaining aseptic environments in healthcare settings.

- Customization & Modularity: Solutions designed to be adaptable to individual patient needs, offering varied firmness zones, interchangeable components, and compatibility with a wide range of bed frames.

- Sustainability: Increasing demand for environmentally friendly manufacturing processes and recyclable materials without compromising performance or durability.

These trends underscore the importance of investing in technologies that not only provide comfort but also deliver measurable clinical outcomes, reducing the burden of pressure injuries on both patients and healthcare systems. The best medical mattress for bedsores solutions are those that effectively integrate these innovations.

The Science Behind Gel Pressure-Relief Mattresses

The effectiveness of a gel mattress stems from its unique viscoelastic properties, which allow it to conform precisely to the patient's body contours. Unlike traditional foam or air mattresses, gel materials offer a distinct combination of fluid-like behavior and solid structural support. Key scientific principles include:

- Viscoelasticity: Gel polymers exhibit both viscous (flow) and elastic (deformation recovery) characteristics. This allows the material to slowly conform to the body shape under pressure, distributing weight over a larger surface area and reducing peak pressure points, which are primary contributors to tissue ischemia and pressure injury development.

- Heat Dissipation: Many medical-grade gels incorporate high thermal conductivity properties or have an open-cell structure that facilitates airflow. This helps in dissipating heat away from the patient's skin, preventing moisture buildup and maintaining an optimal skin microclimate, critical for skin integrity and preventing maceration.

- Shear Force Reduction: Shear forces occur when layers of tissue slide over each other, damaging blood vessels and soft tissues. Gel materials, with their inherent ability to allow slight movement within the material itself, effectively reduce the shear forces exerted on the skin as a patient moves or is repositioned, significantly lowering injury risk.

- Pressure Redistribution: The primary function. By conforming to the unique contours of the body, gel minimizes pressure on bony prominences (sacrum, heels, occiput), where pressure injuries most commonly develop. This redistribution mimics the effect of flotation, offering consistent support without bottoming out.

These properties make the gel mattress a superior choice for patients at high risk of pressure injuries, offering a proactive and scientifically-backed solution within comprehensive medical care protocols.

Manufacturing Process of Advanced Medical Mattresses for Optimal Medical Care

The production of high-performance pressure-relief mattresses involves a meticulously controlled, multi-stage process to ensure product integrity, efficacy, and compliance with stringent medical device standards. This process emphasizes precision engineering and quality assurance at every step.

1. Material Procurement & Inspection

Sourcing of medical-grade polymers, raw gel compounds (e.g., thermoplastic elastomers, polyurethane gels), high-resilience foams, and impermeable, breathable cover fabrics. All materials undergo rigorous incoming inspection for purity, consistency, and compliance with biocompatibility standards (e.g., ISO 10993).

2. Gel Formulation & Molding

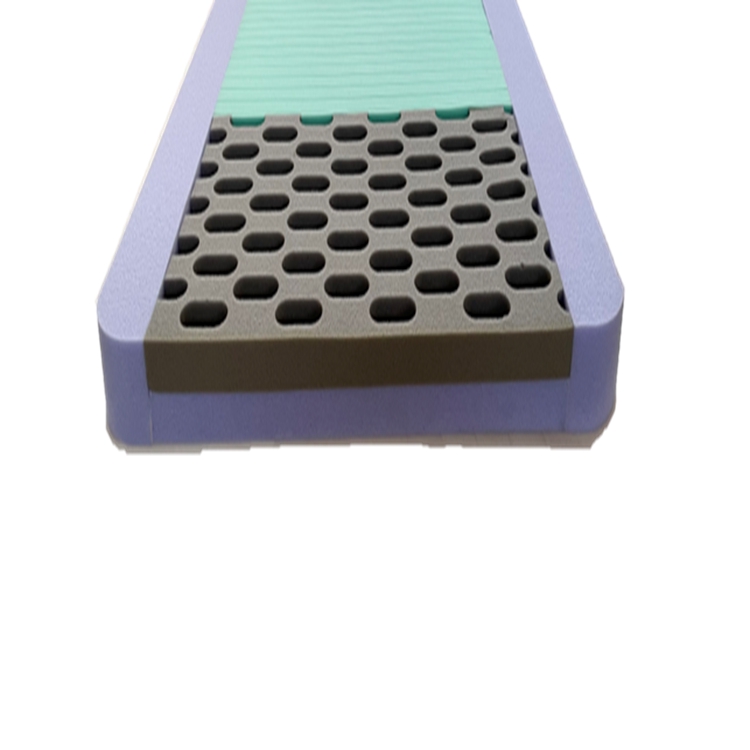

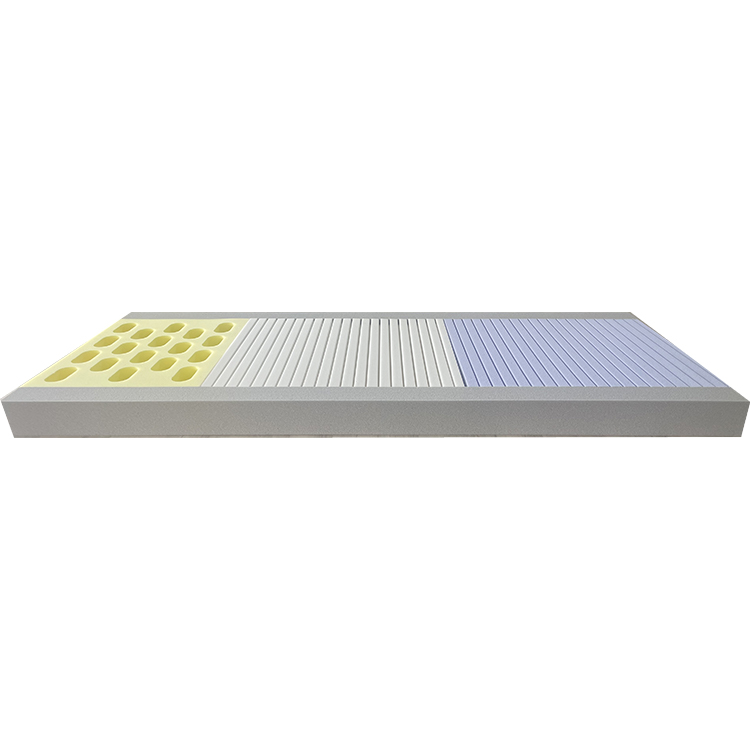

Precise mixing of gel components to achieve desired viscoelastic properties. Gel is then cast or molded into specific configurations (e.g., grids, solid layers, interconnected cells) to create pressure-redistributing zones. This stage may involve specialized casting or injection molding techniques to ensure uniform density and eliminate air pockets.

3. Foam Core Fabrication

High-density and high-resilience foams are cut, profiled, and layered using CNC machining or precision cutting equipment. These foam layers provide structural support, edge stability, and often form the base for the gel layers, contributing to the overall pressure redistribution system.

4. Layering & Assembly

The gel components are meticulously integrated with the foam layers to create a multi-zoned system. Advanced adhesive bonding techniques are used to ensure secure and durable lamination of layers without compromising material properties. Each layer is strategically placed to optimize pressure relief for different body regions.

5. Cover Fabrication & Fitting

The mattress core is enclosed in a protective cover made from vapor-permeable, fluid-proof, antimicrobial, and often flame-retardant fabric. Covers are precisely cut and sewn, often with welded seams, to prevent fluid ingress and facilitate cleaning. Zippers or closure systems are integrated for easy removal and maintenance.

6. Quality Control & Testing

Every mattress undergoes rigorous testing, including pressure mapping (e.g., using F-Scan systems to analyze pressure points), durability testing (e.g., repeated compression cycles to simulate extended use), flame retardancy testing (e.g., CAL 117, BS 7177), and fluid impermeability tests. Compliance with ISO 13485 (Medical Devices Quality Management System) and relevant FDA/CE regulations is paramount.

Service Life & Target Industries:

With proper maintenance, a high-quality medical mattress, especially a gel mattress, is designed for a service life of 5-7 years in continuous institutional use, often exceeding this in home care settings. Our products are engineered for demanding environments where consistent pressure injury prevention is critical. Target industries include:

- Hospitals (Acute Care, ICU, ER, Surgical Recovery)

- Long-Term Care Facilities & Nursing Homes

- Rehabilitation Centers

- Home Healthcare Providers

- Palliative Care and Hospice Facilities

Advantages in these scenarios include superior pressure redistribution, reduction of shear and friction, enhanced microclimate management, and infection control, directly contributing to improved patient outcomes and operational efficiency within comprehensive medical care programs.

Technical Specifications: Gel Pressure-Relief Mattress

Our Gel Pressure-Relief Mattress, designed for optimal patient comfort and pressure injury prevention, incorporates advanced material science and ergonomic design. Below are detailed specifications for the product available at xinmattress.com.

| Parameter | Specification |

|---|---|

| Product Name | Gel Pressure-Relief Mattress |

| Core Material | Multi-layered composite: Viscoelastic Gel infused top layer, High-Density Polyurethane Foam base, Contouring memory foam intermediate layer. |

| Gel Type | Medical-grade, non-toxic, temperature-neutral gel formulation. |

| Cover Material | Fluid-proof, vapor-permeable, anti-microbial, stretch fabric (e.g., Polyurethane-coated Nylon), zipper closure, welded seams. |

| Standard Dimensions (L x W x H) | 80" x 36" x 6" (203 cm x 91 cm x 15 cm) - Custom sizes available. |

| Weight Capacity | Up to 500 lbs (227 kg). |

| Pressure Zones | Multi-zoned design for targeted pressure relief on sacrum, heels, and occiput. |

| Flammability Standards | Meets CAL 117, NFPA 701 (or equivalent international standards like BS 7177). |

| Cleaning & Maintenance | Wipeable, washable cover. Compatible with common hospital disinfectants. |

| Certifications | ISO 13485 (Manufacturing), CE Mark, FDA (as applicable for medical devices). |

| Warranty | 7-year limited warranty on mattress core, 2-year on cover. |

This medical mattress is engineered to provide the optimal combination of comfort, durability, and clinical effectiveness, making it a reliable component of any comprehensive patient care plan. It stands out as a strong candidate for the best medical mattress for bedsores due to its thoughtful design and robust material selection.

Application Scenarios for Optimal Medical Care

The versatility and superior performance of gel pressure-relief mattresses make them indispensable across a variety of healthcare settings, supporting diverse patient populations and ensuring high-quality medical care.

- Acute Care Hospitals: Essential in Intensive Care Units (ICUs), post-operative recovery rooms, and general medical-surgical wards for patients with limited mobility, extended bed rest, or those recovering from complex procedures. The immediate and consistent pressure redistribution capabilities are crucial in preventing rapid onset pressure injuries.

- Long-Term Care Facilities & Nursing Homes: Caters to residents with chronic conditions, advanced age, or neurological impairments, who are at consistently high risk for pressure injury development. The durability and ease of maintenance of a gel mattress are particularly beneficial in these high-utilization environments.

- Home Healthcare for Chronic Conditions: Supports individuals managed at home who require prolonged bed rest due to conditions like spinal cord injury, stroke, degenerative diseases, or advanced cancer. These mattresses enhance patient comfort, reduce caregiver burden, and improve the overall quality of home-based medical care.

- Rehabilitation Centers: Integral for patients undergoing rehabilitation, offering support during periods of rest while minimizing the risk of skin breakdown. It allows patients to focus on therapeutic activities without the added complication of pressure injuries.

- Bariatric Care: Specialized bariatric versions of the gel mattress are designed with increased weight capacities and broader dimensions to accommodate bariatric patients, ensuring effective pressure redistribution for this vulnerable population.

In all these scenarios, the primary goal is to provide a supportive and healing environment, and the best medical mattress for bedsores significantly contributes to achieving this objective by minimizing pressure, shear, and moisture. This proactive approach to patient support is fundamental to comprehensive medical care.

Technical Advantages of Gel Mattresses in Medical Care

Gel pressure-relief mattresses offer a distinct array of technical advantages over traditional support surfaces, positioning them as a cornerstone of advanced patient management strategies:

- Superior Pressure Redistribution: The viscoelastic nature of gel allows for unparalleled contouring to the body, effectively distributing pressure over a wider area and significantly reducing localized peak pressures on bony prominences. This is a critical factor in preventing the initiation of pressure injuries.

- Enhanced Temperature Regulation: Modern gel mattress designs often incorporate advanced cooling gels or structures that promote airflow, preventing heat build-up. This active thermal management maintains an optimal skin microclimate, reducing moisture and the risk of skin maceration.

- Minimization of Shear and Friction Forces: Gel materials inherently reduce friction between the patient's skin and the mattress surface. The internal fluid-like movement within the gel layers also minimizes shear forces when patients are repositioned or move, protecting capillary beds from damage.

- Durability and Longevity: High-quality medical-grade gels and foams are engineered for resilience and resistance to compression set. This ensures that the mattress maintains its pressure-relieving properties over an extended service life, providing consistent performance in demanding clinical environments.

- Infection Control & Ease of Cleaning: Mattresses designed for medical care typically feature fluid-proof, vapor-permeable, and antimicrobial covers. Welded or sealed seams prevent pathogen ingress, and the surfaces are easily cleaned and disinfected with standard hospital-grade solutions, crucial for maintaining hygiene standards.

- Patient Comfort and Stability: While providing excellent pressure relief, gel mattresses also offer stable support that facilitates patient movement and transfers. The contouring ability adapts to the patient's unique body shape, enhancing overall comfort and reducing restlessness.

- Cost-Effectiveness: While the initial investment might be higher than basic foam mattresses, the long-term cost savings from reduced pressure injury incidence, shorter hospital stays, and lower treatment costs for complications make the best medical mattress for bedsores a highly cost-effective solution.

These advantages collectively underscore why gel pressure-relief mattresses are a superior choice for delivering comprehensive and effective medical care, particularly in preventing and managing pressure-related skin conditions.

Vendor Comparison: Choosing the Best Medical Mattress for Your Facility

Selecting the right supplier for pressure-relief mattresses is a critical decision that impacts patient care, operational efficiency, and long-term costs. When evaluating vendors, several key criteria should be considered beyond just the product's immediate specifications.

- Certifications and Compliance: Verify adherence to international quality management standards (e.g., ISO 13485 for medical devices) and relevant regulatory clearances (e.g., FDA, CE Mark).

- Research & Development Investment: A strong R&D focus indicates a commitment to innovation and continuous improvement in pressure injury prevention technologies.

- Customization Capabilities: The ability to provide bespoke solutions for unique facility needs or specialized patient populations is a significant advantage.

- After-Sales Support & Warranty: Comprehensive warranty policies and responsive technical and clinical support are crucial for product longevity and optimal utilization.

- Clinical Evidence & Test Data: Look for vendors who provide clear, data-driven evidence of their product's efficacy, including pressure mapping results and durability tests.

| Feature | Competitor A (Premium Gel Foam) | Competitor B (Standard Gel Hybrid) | XinMattress (Gel Pressure-Relief Mattress) |

|---|---|---|---|

| Core Construction | Gel-infused memory foam + HD foam base | Gel pockets + foam base | Viscoelastic Gel layer + contouring memory foam + HD polyurethane foam base |

| Pressure Redistribution | Good (gel infusion aids) | Very Good (localized gel pockets) | Excellent (full top layer gel + multi-zone foam) |

| Temperature Management | Fair (gel infusion helps, can still retain some heat) | Good (gel has some cooling properties) | Very Good (temperature-neutral gel, vapor-permeable cover) |

| Shear & Friction Reduction | Good | Good | Excellent (viscoelastic properties actively reduce shear) |

| Cover Material | Fluid-resistant, breathable | Fluid-proof, stretch | Fluid-proof, vapor-permeable, anti-microbial, welded seams |

| Certifications | CAL 117, sometimes ISO | CAL 117, CE | ISO 13485, CE, FDA (as applicable), CAL 117 |

| Warranty (Core) | 5 Years | 5-7 Years | 7 Years |

| Customization Options | Limited | Moderate (size variations) | Extensive (size, firmness, bariatric, integrated features) |

This comparison highlights XinMattress's commitment to delivering a comprehensive solution that excels in key performance metrics, regulatory compliance, and adaptability, making it the best gel mattress choice for discerning healthcare providers.

Customized Solutions for Diverse Medical Care Needs

Recognizing that no two patient populations or facility requirements are identical, XinMattress specializes in providing tailored pressure-relief solutions. Our approach to customization ensures that each medical mattress perfectly aligns with specific clinical demands, optimizing patient comfort and safety.

- Size and Dimension Variations: Beyond standard bed sizes, we offer custom lengths, widths, and thicknesses to fit unique hospital beds, stretchers, gurneys, or home care beds, including pediatric and bariatric dimensions.

- Firmness and Support Profiles: Mattresses can be engineered with varying firmness levels or distinct support zones to address specific patient conditions, such as areas requiring additional support or enhanced immersion.

- Integrated Features: Customization can include cut-outs for medical devices (e.g., tracheostomy, ostomy), integrated raised perimeters for fall prevention, or specialized heel pressure relief sections.

- Material Composition Adjustments: We can fine-tune the ratio and type of gel and foam layers to achieve specific pressure redistribution, temperature management, or durability characteristics suited for particular risk levels or clinical protocols.

- Cover Material Enhancements: Options for specialized cover materials that offer heightened fire retardancy, extreme fluid impermeability, or advanced anti-microbial properties for infection-sensitive environments.

Our consultative approach begins with a thorough assessment of your facility's needs, patient demographics, and existing infrastructure. This allows us to design and manufacture a medical mattress solution that provides the best medical mattress for bedsores for your specific context, integrating seamlessly into your overall medical care strategy.

Application Case Studies & Customer Experience

Real-world application demonstrates the tangible benefits of integrating high-quality gel pressure-relief mattresses into diverse healthcare settings.

Case Study 1: Large Urban Hospital Network (Acute Care)

Challenge: A large hospital network faced persistent challenges with HAPIs (Hospital Acquired Pressure Injuries) in their ICU and medical-surgical units, leading to increased patient suffering and significant unreimbursed costs. Existing foam mattresses were failing to adequately protect high-risk patients.

Solution: The network implemented XinMattress Gel Pressure-Relief Mattresses across several critical care units. A pilot program tracked patient outcomes over six months.

Results: Over the six-month period, the incidence of Stage II or higher pressure injuries in the pilot units decreased by 45%. Patients reported significantly improved comfort levels, and nurses noted easier patient repositioning due to the mattress's lower friction surface. The network projected annual savings of over $500,000 from reduced treatment costs and improved patient throughput, affirming the medical care enhancement.

Case Study 2: Regional Long-Term Care Facility (Chronic Care)

Challenge: A long-term care facility struggled with a high prevalence of pressure injuries among its elderly and neurologically impaired residents. Frequent mattress replacements and ongoing wound care represented a substantial operational burden.

Solution: The facility replaced all their older mattresses with XinMattress Gel Pressure-Relief Mattresses, specifically chosen for their durability and superior pressure redistribution for chronic residents.

Results: Within a year, the facility reported a 30% reduction in new pressure injury occurrences. Caregiver feedback highlighted the ease of cleaning and the robust construction of the mattresses, which simplified maintenance protocols. Residents experienced improved sleep quality and reduced discomfort, leading to a notable improvement in overall well-being and a testament to effective medical care.

Customer Feedback Highlights:

- "The durability is unmatched. After years of heavy use, our XinMattress gel units still perform like new." - Director of Purchasing, Metropolitan Hospital.

- "Our patients consistently report feeling more comfortable and sleeping better since we switched to these gel mattresses. It's a game-changer for long-term recovery." - Head Nurse, Rehabilitation Clinic.

- "The ease of cleaning and infection control features have significantly streamlined our daily operations." - Infection Control Specialist, Nursing Home Group.

Ensuring Trustworthiness and Support in Medical Care Solutions

Our commitment extends beyond providing superior products; we prioritize building lasting partnerships based on transparency, reliability, and robust support, crucial elements for effective medical care infrastructure.

Certifications & Authoritative Standards:

Our manufacturing processes and products strictly adhere to international medical device quality and safety standards. This includes:

- ISO 13485:2016 Certification: Demonstrates our comprehensive quality management system for the design, development, production, and servicing of medical devices.

- CE Mark: Signifies compliance with European Union health, safety, and environmental protection standards.

- FDA Compliance (as applicable): Our products meet the stringent requirements of the U.S. Food and Drug Administration for medical devices.

- Fire Retardancy Standards: Compliant with CAL 117, NFPA 701, and other regional fire safety regulations.

Frequently Asked Questions (FAQ):

A: Gel mattresses offer superior pressure redistribution by conforming to body contours, significantly reducing peak pressure points. They also excel in managing skin microclimate by dissipating heat and reducing shear forces, which are critical factors in preventing pressure injury development, making them ideal for high-risk patients.

A: Our mattresses are engineered for durability, offering a 7-year limited warranty on the core. With proper care and maintenance, they are designed to perform effectively for 5-7 years in demanding institutional settings.

A: Our standard dimensions are compatible with most common hospital and long-term care bed frames. We also offer customized sizes and designs to ensure perfect fit and functionality for specialized equipment.

A: The fluid-proof cover is designed for easy cleaning. It can be wiped down with common hospital-grade disinfectants. For deep cleaning, covers can typically be removed via the zipper and are often machine washable according to specific instructions (refer to product manual).

Lead Time & Fulfillment Details:

Standard orders for our Gel Pressure-Relief Mattress typically have a lead time of 2-4 weeks from order confirmation to shipment, depending on quantity. For large volume or customized orders, specific timelines will be provided during the quotation process. We maintain efficient supply chain logistics to ensure timely delivery to healthcare facilities globally.

Warranty Commitments:

We stand by the quality of our products with a comprehensive warranty:

- Mattress Core: 7-year limited warranty against manufacturing defects and premature degradation of pressure-relieving properties.

- Cover: 2-year limited warranty against defects in material and workmanship.

Full warranty details are provided with each product and available upon request.

Customer Support & After-Sales Service:

Our dedicated customer support team is available to assist with product inquiries, order processing, technical support, and after-sales service. We offer:

- Expert product consultation and selection guidance.

- Responsive technical assistance for maintenance and troubleshooting.

- Efficient handling of warranty claims and replacement parts.

Contact us via our website at www.xinmattress.com, by email at sales@xinmattress.com, or by phone at [+1-XXX-XXX-XXXX]. Our goal is to ensure your complete satisfaction and support your commitment to outstanding medical care.

Conclusion

The strategic integration of advanced pressure-relief mattresses, particularly the gel mattress, into comprehensive medical care protocols is no longer merely an option but a necessity. By leveraging cutting-edge material science, precise manufacturing, and a deep understanding of patient needs, manufacturers like XinMattress deliver solutions that significantly enhance patient safety, comfort, and clinical outcomes while providing long-term operational value to healthcare providers. The data-driven advantages of these specialized mattresses, combined with robust support and customization capabilities, position them as indispensable tools in the ongoing fight against pressure injuries, securing a future of elevated patient care standards across the globe.

References

- National Pressure Injury Advisory Panel (NPIAP). Pressure Injury Prevention and Treatment Guidelines.

- European Pressure Ulcer Advisory Panel (EPUAP) & Pan Pacific Pressure Injury Alliance (PPPIA). Prevention and Treatment of Pressure Ulcers/Injuries: Clinical Practice Guideline.

- ISO 13485:2016 Medical devices — Quality management systems — Requirements for regulatory purposes.

- FDA, Center for Devices and Radiological Health. Medical Device Regulations.

- Agency for Healthcare Research and Quality (AHRQ). Preventing Pressure Ulcers in Hospitals: A Toolkit for Improving Quality of Care.

- Bergstrom N, et al. The Braden Scale for Predicting Pressure Sore Risk: Development and Conceptual Foundation. Nursing Research. 1987.

-

The Truth About "Orthopedic" Mattresses for Sore Back PainNewsAug.23,2025

-

Space-saving Benefits of a Single Mattress CubeNewsAug.23,2025

-

Eco-friendly Advantages of a Silicon MattressNewsAug.23,2025

-

How to Fix Sagging in a Special MattressNewsAug.23,2025

-

How Ambulance Stretcher Mattresses Reduce Pressure InjuriesNewsAug.23,2025

-

Best Cleaning Practices for a Hospital Mattress DoubleNewsAug.22,2025

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025