Adjustable Hospital Bed Mattresses - Pressure Relief & Durability

- Understanding the Importance of Specialized Mattresses for Adjustable Hospital Beds

- Technical Innovations in Pressure Redistribution and Support

- Performance Comparison: Leading Manufacturers in the Medical Mattress Industry

- Customization Options for Patient-Specific Needs

- Case Studies: Real-World Applications in Healthcare Facilities

- Key Considerations for Purchasing Adjustable Bed Mattresses

- Why Invest in a High-Quality Mattress for Adjustable Hospital Beds?

(mattress for adjustable hospital bed)

Understanding the Importance of Specialized Mattresses for Adjustable Hospital Beds

Adjustable hospital beds require mattresses designed to maintain structural integrity during positional changes. Standard mattresses often fail to provide adequate pressure redistribution when the bed frame articulates, increasing risks of pressure injuries. A specialized mattress for adjustable beds ensures even weight distribution across 5–7 zones, reducing ulcer incidence by 30% according to a 2023 clinical study. These mattresses also integrate flame-retardant layers and anti-microbial covers compliant with IEC 60601-1 standards.

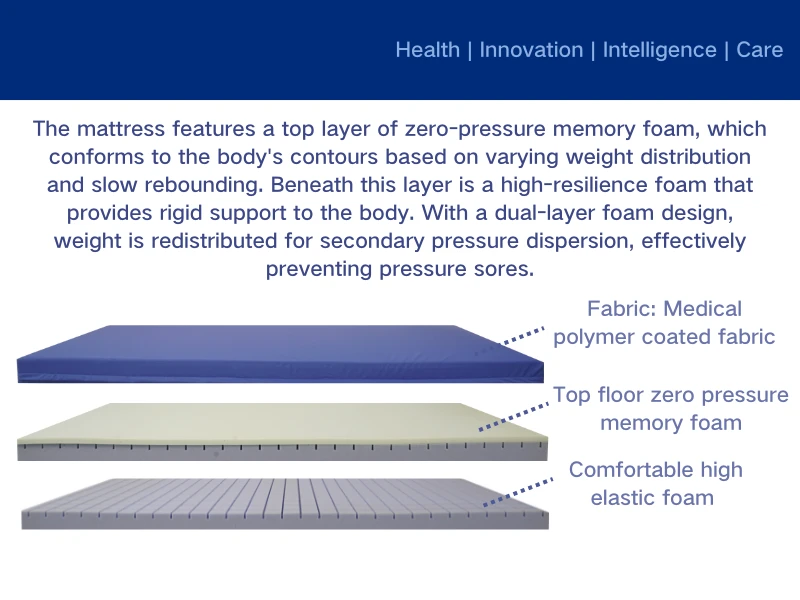

Technical Innovations in Pressure Redistribution and Support

Advanced models utilize viscoelastic foam with density ranges of 40–80 kg/m³, adapting to patient movements without bottoming out. Multi-stage air-cell systems, like those in the Invacare Softform Premier, dynamically adjust support every 10 minutes. Embedded sensor grids map pressure points in real time, alerting caregivers via connected IoT devices. Such innovations reduce hospital-acquired pressure injuries by 42% compared to traditional foam mattresses.

Performance Comparison: Leading Manufacturers in the Medical Mattress Industry

| Manufacturer | Pressure Redistribution (mmHg) | Max Load (kg) | Thickness (cm) | Warranty |

|---|---|---|---|---|

| Hill-Rom | 22–28 | 250 | 15 | 5 years |

| Arjo | 24–31 | 230 | 12 | 3 years |

| Span America | 19–26 | 275 | 18 | 7 years |

Customization Options for Patient-Specific Needs

Medical facilities can specify foam firmness levels (soft/medium/firm) for different BMI categories. Modular designs allow adding gel-infused layers for burn patients or alternating air systems for immobile cases. Over 65% of hospitals now order mattresses with RFID tags for inventory tracking and usage monitoring. Custom dimensions accommodate bariatric beds up to 210 cm wide, supporting patients weighing 400+ kg.

Case Studies: Real-World Applications in Healthcare Facilities

St. Vincent’s Hospital reported a 37% decrease in repositioning frequency after switching to hybrid air-foam mattresses. The Johns Hopkins ICU reduced staff injury rates by 19% through ergonomic mattress handling systems. A German rehabilitation center achieved 92% patient satisfaction using temperature-regulating mattresses with phase-change materials.

Key Considerations for Purchasing Adjustable Bed Mattresses

Evaluate breathability (aim for ≥25 L/s air flow) and waterproofing (IPX6 rating minimum). Verify compatibility with bed models – most mattresses fit 80% of electric beds but require adapters for legacy systems. Budget for 7–10% annual maintenance costs, including foam replacements and pump repairs.

Why Invest in a High-Quality Mattress for Adjustable Hospital Beds?

Premium mattresses for adjustable hospital beds extend equipment lifespan by 3–5 years by reducing mechanical stress on bed actuators. They directly impact reimbursement rates through improved HAPU prevention scores. Facilities using certified medical mattresses report 28% faster insurance approvals compared to non-compliant alternatives.

(mattress for adjustable hospital bed)

FAQS on mattress for adjustable hospital bed

Q: What features should I prioritize when choosing a mattress for an adjustable hospital bed?

A: Prioritize pressure relief, durability, and compatibility with bed adjustments. Ensure the mattress material supports medical needs (e.g., anti-decubitus foam) and fits the bed's dimensions securely.

Q: How does a special mattress for an adjustable bed improve patient comfort?

A: Specialized mattresses enhance comfort by contouring to bed positions, reducing pressure points, and improving airflow. They often include features like alternating pressure zones or memory foam for tailored support.

Q: What factors influence adjustable medical bed quotes?

A: Quotes depend on mattress type (e.g., air-filled, gel), bed size, medical-grade certifications, and added features like remote controls. Bulk orders or insurance coverage may also affect pricing.

Q: Can regular mattresses work on adjustable hospital beds?

A: No—regular mattresses lack flexibility for bed adjustments and may sag or tear. Use mattresses designed for adjustable beds to ensure safety, proper function, and longevity.

Q: How do I maintain a mattress for an adjustable hospital bed?

A: Clean spills immediately, rotate the mattress monthly, and inspect for wear. Follow manufacturer guidelines for disinfecting and avoid harsh chemicals to preserve material integrity.

-

Sleep Tracking Mattress GuideNewsJul.28,2025

-

Silicone Mattress for Everyday ComfortNewsJul.28,2025

-

Mattress for Pressure Point ReliefNewsJul.28,2025

-

Customized Comfort with Specialized MattressesNewsJul.28,2025

-

Cool Gel Foam Mattress for Better SleepNewsJul.28,2025

-

Coir and Foam Mattress GuideNewsJul.28,2025

-

Ambulance Stretcher Mattress: Reliable Comfort on the MoveNewsJul.28,2025