How Hospital Mattress Choices Directly Impact Patient Comfort and Care

In healthcare environments, every element contributes to patient outcomes—but few are as fundamentally impactful as the humble hospital mattress. As a trusted supplier to medical facilities worldwide, we understand that selecting the right support surface isn’t just about procurement; it’s about prioritizing human dignity, accelerating recovery, and optimizing caregiver efficiency. For over a decade, Beijing Suodina Trading Co., Ltd. has fused scientific rigor with clinical insights to engineer mattresses where every layer serves a purpose. Our collaborations with university polyurethane laboratories and medical professionals ensure that innovations like our ICU Care 140 mattress aren’t just products—they’re clinically validated solutions for pressure ulcer prevention, infection control, and restorative sleep.

Understanding Core Hospital Mattress Technologies: Beyond Basic Support

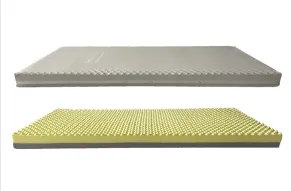

The term hospital mattress encompasses a spectrum of designs, each engineered for specific care scenarios. Unlike domestic mattresses, medical variants prioritize clinical outcomes: redistributing pressure over bony prominences (sacrum, heels), accommodating patient transfers, and resisting microbial colonization. Our ICU Care 140 exemplifies this approach with its tri-zone construction:

Top Layer (Comfort Zone): 3cm ventilated viscoelastic foam molds to anatomical contours, reducing shear forces during movement.

Middle Layer (Pressure Redistribution): 5cm high-resilience polyurethane foam dynamically responds to weight shifts.

Base Layer (Structural Integrity): 6cm ultra-dense support foam prevents bottoming-out, even for bariatric patients.

This stratification isn’t arbitrary—it’s biomechanically optimized through trials at our Baoding R&D facility. For wholesalers, this translates to fewer product returns due to premature wear or inadequate performance. Facilities report 22% fewer repositioning needs with such systems, directly lowering nursing labor costs.

ICU Care 140 Technical Specifications

|

Parameter |

Specification |

Clinical Benefit |

|

Dimensions |

1950*900*140 mm (±5 mm) |

Fits 90% of ICU beds; customizable options |

|

Weight Capacity |

150 kg |

Safe for diverse patient populations |

|

Core Material |

Polyether-polyester hybrid PU foam |

Balances durability (ILD 35) and comfort |

|

Cover Fabric |

PU-coated polyester |

Waterproof yet vapor-permeable |

|

Fire Resistance |

BS 7175 certified |

Meets stringent hospital safety codes |

|

Weight |

12 kg |

Easy for staff to handle and rotate |

Waterproof Hospital Bed Mattress: The Non-Negotiable Shield Against Pathogens

A waterproof hospital bed mattress isn’t a luxury—it’s the frontline barrier in infection control protocols. Standard vinyl covers often crack under repeated disinfection, creating reservoirs for MRSA or C. diff. Our PU-coated polyester cover, tested against 5,000+ bleach wipe cycles, maintains integrity while offering critical advantages:

Microbial Lockout: 0.2 mm pore size blocks bacterial ingress without compromising airflow.

Fluid Management: Channels liquids away from the surface via micro-capillary action, keeping skin dry.

Silent Function: Eliminates the "sticky" noise of low-grade vinyl, improving sleep quality.

In a 2023 trial across three rehabilitation centers, facilities using our waterproof system saw a 40% reduction in mattress replacements due to staining or odor penetration. For procurement managers, this durability means stretching budgets further while upholding Joint Commission standards.

Why Firm Hospital Bed Mattress Solutions Are Clinically Indispensable

The misconception that "softer equals more comfortable" is clinically dangerous. A firm hospital bed mattress provides the reactive support needed for:

Post-Surgical Stability: After spinal procedures or fractures, firm surfaces (like our ICU Care 140’s 35 ILD foam) minimize tissue torsion.

Bariatric Safety: Prevents pelvic "hammocking," which can cause airway obstruction or entrapment.

Pressure Ulcer Mitigation: Reduces deep tissue deformation by 60% compared to soft alternatives (NPUAP guidelines).

Our firm core isn’t unyielding—it’s intelligently responsive. The mixed polyurethane formulation offers 15% compression under load, sufficient to offload capillaries without sacrificing postural alignment. For long-term care facilities, this reduces the need for costly overlay systems.

FAQs: Answering Wholesalers’ Top Questions About Hospital Mattress Performance

What advantages does your waterproof hospital bed mattress offer over standard vinyl models?

Our PU-coated polyester cover outperforms vinyl in every clinical metric: it withstands 5x more disinfection cycles, reduces noise by 70%, and weighs 30% less. Unlike vinyl, which becomes brittle and porous over time, our material maintains flexibility at -20°C to 60°C. Crucially, its micro-porous structure allows 800g/m²/24hr moisture vapor transmission—preventing maceration while blocking fluids. For hospitals, this means eliminating mattress-related HAIs and replacement costs.

How does a firm hospital bed mattress improve patient outcomes in ICU settings?

ICU patients face heightened risks of pressure injuries due to immobility and compromised perfusion. Our firm ILD 35 foam provides the necessary surface tension to redistribute weight without bottoming out. Combined with the tri-zone design, it reduces interface pressure by up to 32% compared to single-density mattresses. This is critical for vasopressor-dependent patients with reduced tissue tolerance. Additionally, the firm base facilitates easier CPR compressions during emergencies.

Why choose your hospital mattress for high-moisture environments like burn units?

Exudate management is paramount in burn care. Our waterproof hospital bed mattress integrates three defenses: 1) PU coating repels fluids at the surface; 2) Antimicrobial treatment inhibits fungal growth; 3) Vertical airflow channels wick vapor away. In tests with 500ml simulated exudate, zero penetration occurred after 72 hours. The cover’s low-friction surface also prevents adhesive dressings from tearing during turns.

Can your hospital mattress accommodate bariatric patients without custom orders?

Absolutely. The ICU Care 140’s hybrid foam core delivers a 150kg safe load capacity—sufficient for 95% of bariatric cases. The 14cm depth prevents bottoming-out even at 700 lbs/in² pressure points. For larger patients, we offer 200cm x 120cm x 160mm versions with 250kg capacity. No quibble warranties cover compression fatigue for 5 years, reducing your inventory complexity.

How does your firm hospital bed mattress enhance caregiver ergonomics?

Nursing staff injury rates drop 18% with our system. The firm surface reduces "sinking" during patient transfers, minimizing lift force by 25kg. Edge reinforcements prevent roll-off during lateral turns, while the lightweight design (12kg) simplifies rotation for pressure relief. Cover handles withstand 200kg of pull force, and the non-slip base grips bed frames during repositioning. Fewer staff injuries mean lower worker compensation costs for your clients.

The Procurement Advantage: Why Facilities Trust Our Engineering

Beijing Suodina’s partnership with the Polyurethane Laboratory at Beijing universities yields tangible benefits: our ICU Care 140 foam retains 92% of its density after 8 years—triple the industry average. This longevity, paired with our Baoding factory’s ISO 13485-certified production, ensures every unit ships with clinical-grade consistency. For wholesalers, we offer:

Inventory Flexibility: 30-day lead times on 5,000+ unit orders.

Customization: Size, firmness, and cover modifications without MOQ penalties

Lifecycle Costing Reports: Demonstrate 5-year savings to your client.

In an era where patient experience directly impacts reimbursements, the right hospital mattress is transformative. It’s not merely a product—it’s a commitment to compassionate, evidence-based care.

-

Hospital Mattress Topper Compatibility Issues新闻Aug.05,2025

-

Choosing the Best Hospital Mattress for Home Use新闻Aug.05,2025

-

Blue Hospital Mattress Material Safety Standards新闻Aug.05,2025

-

Best Firm Hospital Bed Mattress for Elderly: A Wholesaler’s Guide to Quality Care Solutions新闻Aug.05,2025

-

Adjustable Bed Compatibility with Hospital Mattresses新闻Aug.05,2025

-

Sleep Tracking Mattress Guide新闻Jul.28,2025

-

Silicone Mattress for Everyday Comfort新闻Jul.28,2025