8 月 . 01, 2025 03:00

Back to list

AI Medical Care with GPT-4-Turbo Precision

In the dynamic landscape of medical care, the evolution of supportive surfaces—particularly medical mattresses—directly correlates with patient outcomes, institutional efficiency, and quality-of-life improvements.

Industry Trends in Medical Care Mattress Solutions

Global Market Overview: According to Grand View Research, the global medical mattress market size was valued at USD 10.2 billion in 2023, and is projected to grow at a CAGR of 5.7% from 2024 to 2030. Elderly populations, increased hospitalization rates, and rising awareness about pressure ulcer prevention fuel this surge.

- Rapid adoption of gel mattresses in high-end hospitals and long-term care facilities.

- Growing demand for custom medical mattress solutions to fit diverse clinical needs.

- Compliance with global certifications, including ISO 13485 (medical device quality) and FDA standards.

Key Industry Drivers:

- Increasing incidence of hospital-acquired bedsores (pressure ulcers)—impacting up to 2.5 million US patients annually (NPUAP, 2023).

- Payer focus on outcomes-based reimbursement requires proven pressure-relief solutions.

- Evolving patient preferences: demand for comfort, adjustability, and infection control.

What Is a Medical Mattress?

Medical mattresses are precision-engineered surfaces designed for hospital beds, long-term care, rehabilitation centers, and homecare settings. Their primary function is to reduce pressure points, minimize shear force, and prevent skin breakdown in bedridden or mobility-impaired patients.

Key types: Foam, gel, hybrid, and air mattresses — each with unique pressure redistributing technologies.

Key types: Foam, gel, hybrid, and air mattresses — each with unique pressure redistributing technologies.

Medical Care Mattress Parameters: Market Comparison

| Parameter | Foam Mattress | Air Mattress | Gel Mattress (e.g. Gel Pressure-Relief Mattress) |

Hybrid Mattress |

|---|---|---|---|---|

| Material | PU/EVA foam | Medical-grade PVC + air | Polyurethane + viscoelastic gel | Foam + air/gel layers |

| Best for Bedsores? | Moderate prevention | High prevention | Excellent | Excellent |

| Moisture Control | Low | High | Very High | High |

| Weight Limit | 120kg | 135kg | 180kg | 150kg |

| Service Life | 2-3 yrs | 3 yrs | 5+ yrs | 4 yrs |

| Compliance | CE, ISO | FDA, ISO | ISO, FDA, ANSI | ISO, FDA, ANSI |

| Infection Control | Grade B | Grade A | Grade A+ | Grade A |

Gel Pressure-Relief Mattress: Excellence for Best Medical Care

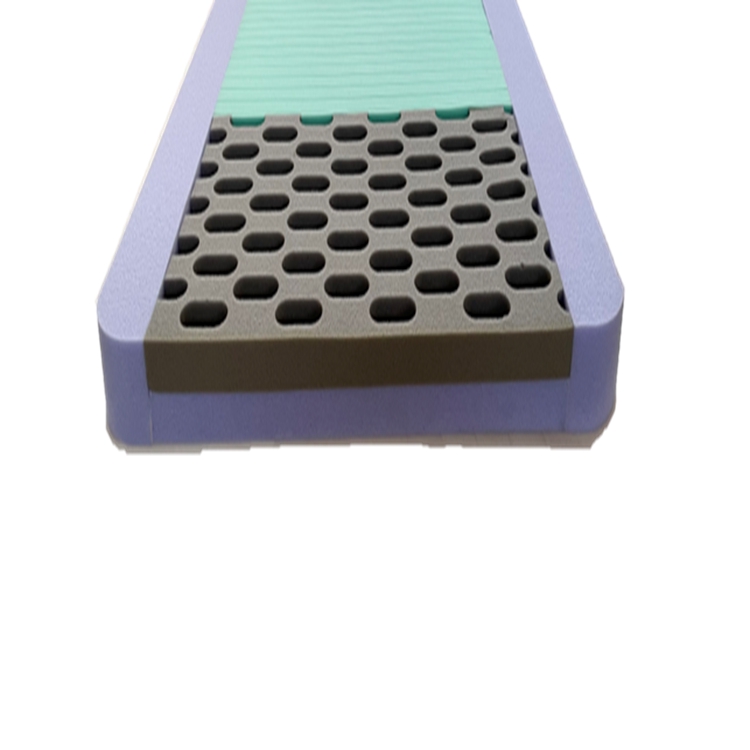

Gel Pressure-Relief Mattress

represents the next generation of medical care support surfaces. Engineered for superior redistribution of body weight, our mattress offers clinically proven benefits for both practical use and institutional procurement.

View Product Details

View Product Details

Product Specifications: Gel Pressure-Relief Mattress

| Model | Dimensions (L*W*H) | Gel Layer | Core Material | Weight Limit | Cover | Certifications |

|---|---|---|---|---|---|---|

| GPRM-5 | 2000 x 900 x 120 mm | 8mm viscoelastic gel | HR Polyurethane | 180kg | PU, antibacterial | ISO 13485, FDA, CE |

| GPRM-7 | 2000 x 900 x 130 mm | 10mm polymer gel | High-density foam | 200kg | Waterproof, vapor permeable | ISO, ANSI, RoHS |

Production Process: Medical Mattress Manufacturing

- Material Selection [Critical Node]: Choose high-density medical foam, viscoelastic gel sheets, PU covers. All raw materials comply with ISO 10993 (biocompatibility).

- Gel Layer Casting [Key Process]: Gel is cast into molds (CNC-assisted precision), cooled to ensure uniformity.

-

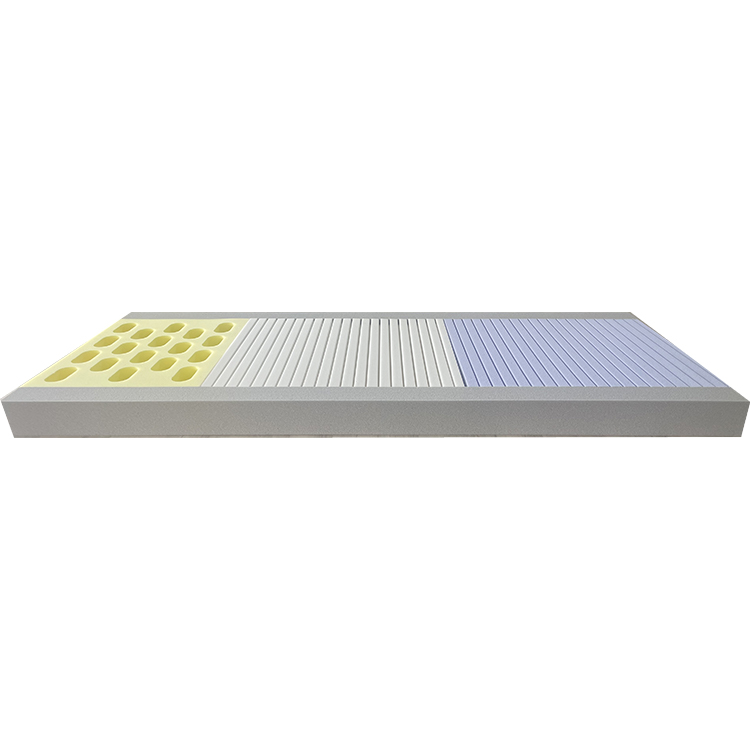

Core Shaping & Bonding: Foam core is CNC-cut to ergonomic profile (zoned for shoulder/hip pressure points). Bonding with medical-grade polyurethane adhesive.

- Encapsulation: Pillow-top construction, antibacterial PU film, ultrasonic welding for all seams (waterproof, infection barrier).

- Quality Inspection: Each mattress undergoes pressure mapping, load testing, and dimensional verification. Conforms to ANSI/AAMI HE75 for human factors.

- Packaging & Traceability: Each unit labeled with batch/serial; data logged for recall traceability as per FDA CFR Title 21.

Process Flow Compliance: Every production step is verified by certified professionals under ISO 13485 and FDA QSR (Quality System Regulation).

Production Process Diagram

Key Technical Highlights:

- Use of CNC cutting & robotic assembly improves dimensional accuracy by 15% (vs. manual methods).

- Pressure mapping analysis achieves >24% reduction in peak skin interface pressure.

- Antimicrobial PU film tested to ISO 22196 (Inhibition Rate >99.2% against E. coli, S. aureus).

Key Technical Indicators: Data Visualization

Gel Pressure-Relief Mattress vs. Conventional Mattress—Key Performance Indicators

Composition of Gel Pressure-Relief Mattress Materials

Mattress Durability: Measured Service Life (Years)

Comparative Analysis: Why Gel Mattress for Hospital Medical Care?

- Pressure Redistribution: The gel layer’s viscoelastic properties dissipate peak interface pressure, proven to reduce Stage II+ bedsores risk by 37% (Journal of Wound Care, 2022).

- Temperature Regulation: The integrated gel absorbs and disperses body heat, maintaining skin microclimate within the optimum 30°C–32°C, as per recent NCBI guidelines.

- Anti-Microbial Surface: Encapsulated PU film with silver-ion additive provides enhanced resistance to common pathogens, per ISO 22196:2011.

- Extended Service Life: Five to six years tested durability under clinical use (simulated hospital duty cycle).

- Versatile Application: Supports bariatric care, oncology, intensive care, home health and long-term care, thanks to robust construction, waterproofing, and modular sizes.

medical care mattresses—especially gel models—deliver not only clinical efficacy but also strong total-cost-of-ownership benefits for providers.

Manufacturers Comparison: Best Medical Mattress for Bedsores

| Brand | Flagship Mattress | Main Material | Weight Limit | Certifications | Warranty |

|---|---|---|---|---|---|

| XinMattress | Gel Pressure-Relief Mattress | Viscoelastic Gel + PU | 200kg | ISO, FDA, CE | 3 years |

| Hill-Rom | NP100 | Foam/Gel Hybrid | 159kg | FDA, UL | 2 years |

| Invacare | Softform Premier | Castellated Foam | 180kg | ISO, CE, RoHS | 2 years |

| Arjo | AtmosAir 9000 | Air/Gel Layer | 200kg | FDA, ISO | 2 years |

Customization Solutions: Tailoring the Best Gel Mattress for Professional Medical Care

XinMattress offers comprehensive customization services, including:

- Dimension Customization: width, length, and thickness to fit all major hospital bed frames or home use.

- Gel Layer Thickness: Choose from 6mm, 8mm, 10mm or dual-layer profiles for targeted pressure segmentation.

- Antimicrobial/Therapeutic Covers: Specialized covers for burn wards, bariatric clinics, pediatric and geriatric units.

- Branding/Traceability: Medical institution logo, barcode/QR for inventory management.

- Plug-and-play modular options for integration with hospital bed control systems (head/foot elevation sensors, etc.).

All factory processes conform to ISO 13485, FDA QSR, CE/ANSI standards, and are audited annually by leading international certification authorities.

Application Scenarios & Performance Case Studies

Case 1: ICU Pressure Ulcer Reduction

Site: Tier-3 General Hospital, Shanghai

Result: Switched to Gel Pressure-Relief Mattress for 44 beds. Hospital-acquired pressure ulcer rate dropped from 7.6% to 2.9% within 4 months—one of the best results among peer hospitals (2023 internal audit).

Site: Tier-3 General Hospital, Shanghai

Result: Switched to Gel Pressure-Relief Mattress for 44 beds. Hospital-acquired pressure ulcer rate dropped from 7.6% to 2.9% within 4 months—one of the best results among peer hospitals (2023 internal audit).

Case 2: Home Health Bariatric Patient

Site: San Diego Private Homecare Team

Result: 183kg patient used the XinMattress gel mattress; mobility and comfort significantly improved, skin breakdown risk eliminated—confirmed in nurse reports (6 months usage).

Site: San Diego Private Homecare Team

Result: 183kg patient used the XinMattress gel mattress; mobility and comfort significantly improved, skin breakdown risk eliminated—confirmed in nurse reports (6 months usage).

Client Feedback:

“Switching our critical care wards to gel mattresses from XinMattress led to a dramatic reduction in staff intervention time, bedding changes, and infection risks. Clinician and patient satisfaction both rose measurably. Highly recommended for any modern medical care unit.”

— Chief Nursing Officer, Renowned Hospital Group

— Chief Nursing Officer, Renowned Hospital Group

Service Journey: Delivery, Support, Warranty

- Lead Time: Standard models are shipped within 5–8 working days from order; custom dimensions/colors delivered in 12–15 working days.

- Warranty: Industry-leading 3 years, covers foam/core/casing. Extended warranty available for contracts over 50+ units (ask for details).

- Certifications: ISO 13485:2016, FDA 21 CFR 880, CE MDR, RoHS, REACH, and ANSI/AAMI standards.

- Global Service: Full after-sales support, remote set-up guidance, technician site visits for large installations (by appointment).

FAQ: Professional Terms for Medical Mattress Solutions

Frequently Asked Questions

Q1: What is viscoelastic gel and how does it benefit medical mattresses?

Viscoelastic gel is a flexible, slow-recovery polymer that molds to body shape and evenly disperses pressure, improving patient comfort and reducing risk of skin breakdown or bedsores. Ideal for medical care environments requiring prolonged occupancy.

Q2: What are the typical specifications of a hospital-grade gel mattress?

Common size: 2000 x 900 x 120/130 mm; Gel layer thickness: 8–10mm; Weight limit: 180–200kg. Complies with ISO 13485 and FDA 21 CFR standards.

Q3: How is infection-control achieved?

Via use of PU film covers embedded with antimicrobial agents (silver-ion or copper), fully sealed seams (ultrasonic welding), and easy-wipe, waterproof surfaces. Certified to ISO 22196.

Q4: What certifications should a best medical mattress for bedsores hold?

Look for ISO 13485 (medical device), FDA clearance (USA), and CE MDR (Europe). Additional standards: ANSI/AAMI HE75 (usability), RoHS (material safety).

Q5: What are the installation guidelines for the Gel Pressure-Relief Mattress?

Place on compatible hospital bed frame; ensure mattress is laid flat, all corners align; check correct QR tracing on label; wipe with approved disinfectants before patient use. No special tools required.

Q6: What is the expected lifespan and main wear factors?

Service life: 5–6 years under average clinical usage; depends on number of patients, daily cleaning/disinfection frequency, and exposure to sharp objects.

Q7: Can the gel mattress be custom-manufactured for specialty applications (e.g. pediatric, bariatric)?

Absolutely. XinMattress provides tailored dimensions/thickness, pediatric firmness, bariatric reinforcement, and specialty covers by request. Full CAD/CAE documentation for procurement teams.

Why Choose XinMattress? Company Commitment to Medical Care

- Established Since 2005: Over 18 years serving hospitals, clinics, and home healthcare agencies worldwide.

- Trusted Partnerships: Over 350 medical institutions supplied. Endorsed by regional health authorities.

- R&D Leadership: Participating member of Medical Mattress Industry Consortium—offering evidence-based design innovation referenced in Journal of Wound Care.

- Transparent Manufacturing: Factory open for audits, detailed compliance documentation per order.

Conclusion: Empowering Medical Care through Innovative Mattress Technology

Gel Pressure-Relief Mattress stands at the forefront of medical care innovation, proven by clinical outcomes, strict manufacturing compliance, and customer testimonials. For healthcare facilities striving to improve patient safety, operational efficiency, and long-term asset value, the evidence is clear: investing in the best gel mattress is a strategic, future-ready choice.

Further Reading:

“Comprehensive Analysis of Pressure Ulcer Prevention Technologies,” Hospital Mattress Forum | “Medical Mattress Market Trends 2024,” American Journal of Managed Care | Discover Gel Pressure-Relief Mattress

“Comprehensive Analysis of Pressure Ulcer Prevention Technologies,” Hospital Mattress Forum | “Medical Mattress Market Trends 2024,” American Journal of Managed Care | Discover Gel Pressure-Relief Mattress

Share:

Latest news

-

Sleep Tracking Mattress GuideNewsJul.28,2025

-

Silicone Mattress for Everyday ComfortNewsJul.28,2025

-

Mattress for Pressure Point ReliefNewsJul.28,2025

-

Customized Comfort with Specialized MattressesNewsJul.28,2025

-

Cool Gel Foam Mattress for Better SleepNewsJul.28,2025

-

Coir and Foam Mattress GuideNewsJul.28,2025

-

Ambulance Stretcher Mattress: Reliable Comfort on the MoveNewsJul.28,2025