Hospital Bed Mattress 36x80 – Waterproof & Pressure Sore Prevention

- Introduction to the Critical Role of 36x80 Hospital Bed Mattresses

- The Stark Reality: Pressure Injury Statistics Demanding Specialized Mattresses

- Engineering Breakthroughs in Medical Mattress Technology

- Leading Brands Performance Comparison Analysis

- Custom Configuration Solutions for Specific Care Scenarios

- Documented Outcomes in Real Clinical Environments

- Implementation Guide: Selecting the Optimal Mattress System

(hospital bed mattress 36 x 80)

Why the 36x80 Hospital Bed Mattress is a Critical Care Component

Specialized hospital bed mattresses measuring 36" x 80" serve as frontline defense in patient care settings. Designed for standard medical bed frames, these critical components directly impact pressure ulcer prevention and rehabilitation outcomes. Unlike conventional mattresses, medical-grade options incorporate targeted pressure redistribution technologies that respond to patients' unique physiological requirements, especially for at-risk individuals.

Immobility patients require surfaces capable of minimizing tissue deformation—research indicates peak pressure points decrease by up to 52% on specialized medical mattresses compared to standard alternatives. The dimensions precisely match institutional bed frames to eliminate dangerous gaps while accommodating patients up to 350lbs. Facilities utilize these solutions across ICU, geriatric, bariatric, and palliative care units where pressure management becomes non-negotiable for care quality.

The Stark Reality: Pressure Injury Statistics Demanding Specialized Mattresses

Healthcare-acquired pressure injuries (HAPIs) present alarming clinical and financial consequences. Approximately 2.5 million patients develop pressure ulcers annually in US acute care facilities, costing between $20,900-$151,700 per injury according to Agency for Healthcare Research data. These preventable complications extend hospital stays by 4-7 days on average while increasing mortality risk by 400%.

High-risk populations exhibit particular vulnerability. For spinal injury patients, pressure ulcer incidence reaches 25-66%. Geriatric units report 15-25% incidence rates among immobile seniors. Waterproof hospital bed mattress technology counters these statistics by creating microclimate control through breathable materials that reduce moisture accumulation—a key factor in skin breakdown. Facilities implementing advanced mattress systems report up to 64% reduction in hospital-acquired pressure injuries within 12 months.

Engineering Breakthroughs in Medical Mattress Technology

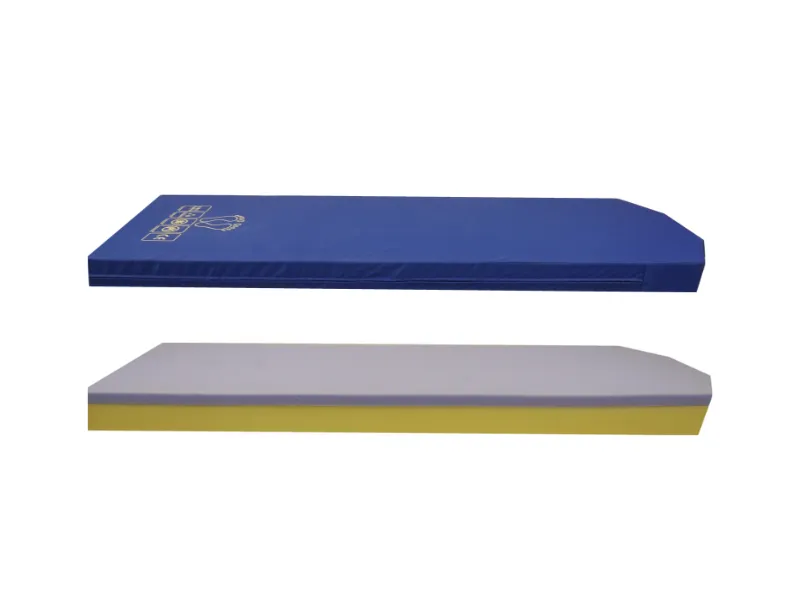

Modern therapeutic mattresses incorporate layered engineering approaches combining multiple pressure management modalities:

- Multicell foam cores with varying ILD (Indentation Load Deflection) ratings strategically distribute weight

- Continuous airflow spacer fabrics that evacuate heat and humidity

- Medical-grade polyurethane coatings providing waterproof protection without compromising breathability

- Viscoelastic memory foam overlays contouring to anatomical pressure points

- Fluid-resistant seams preventing bacterial ingress through double-stitched seams

Cutting-edge advancements include phase-change materials (PCMs) that actively regulate surface temperature and alternating pressure systems with micro-sensors that dynamically redistribute load. Waterproofing technologies deserve particular attention—modern medical mattress covers utilize TPU (thermoplastic polyurethane) membranes with 10,000mm+ water resistance while achieving MVTR (moisture vapor transmission rates) exceeding 3,000g/m²/24hr, preventing maceration without heat retention.

Leading Brands Performance Comparison Analysis

| Manufacturer | Waterproof Protection | Core Technology | Pressure Redistribution | Maximum Weight Capacity | Cover Integrity Warranty |

|---|---|---|---|---|---|

| Invacare MicroAIR | 360° barrier system | 3-layer alternating pressure | 72% reduction at sacrum | 450lbs | 3 years |

| Drive Medical TriMatrix | Laminated TPU coating | Multi-density convoluted foam | 59% overall pressure decrease | 350lbs | 2 years |

| Medline SoftGrip | Welted-edge waterproofing | Viscoelastic + gel infusion | 67% heel pressure reduction | 400lbs | 18 months |

| Span-America Geo-Matrix | Liquid-proof welded seams | Multi-directional column design | 71% hip pressure relief | 500lbs | 5 years |

When evaluating waterproof mattress for hospital bed applications, Span-America's welded construction provides superior fluid containment while Invacare delivers industry-leading pressure mapping results. Facilities treating high-risk bariatric patients should prioritize models with 400lbs+ capacity and reinforced edge support to prevent roll-off incidents.

Custom Configuration Solutions for Specific Care Scenarios

Therapeutic mattresses demand customization based on care environments and patient profiles. For infection control units, antimicrobial silver-ion impregnated covers reduce bacterial colonization by 99.8% within 24 hours of exposure. Bariatric configurations incorporate reinforced perimeter walls and expanded support bases to accommodate patients up to 500lbs without bottoming out.

Memory foam configurations with gradual firmness transition zones (progressive compression resistance) benefit patients with existing bed sores. For home healthcare environments, lightweight models (under 20lbs) featuring removable, bleach-cleanable covers simplify maintenance. Long-term care facilities implement continuous low-pressure models that automatically redistribute pressure points without manual repositioning schedules, reducing staff intervention by 4 hours per patient weekly.

Documented Outcomes in Real Clinical Environments

Mercy Medical Center documented outcomes from switching 220 beds to alternating pressure systems: Stage 3 pressure injuries decreased by 73% within 8 months, reducing treatment costs by $412,000 annually. The Veterans Administration implemented waterproof hospital bed mattress systems across spinal injury units and recorded 61% fewer skin integrity incidents, correlating with a 22% reduction in extended care requirements.

In home care settings, clients utilizing specialized pressure-reducing mattresses reported 4.2 higher comfort scores (10-point scale) compared to conventional mattresses. Perhaps most significantly, facilities conducting quarterly pressure mapping tests extend mattress lifespan by 28% by identifying support deterioration before failure.

Selecting the Ideal 36x80 Waterproof Hospital Bed Mattress

Specification begins with risk assessment—Braden Scale scores under 12 demand high-specification pressure redistribution systems with continuous micro-adjustment capabilities. Waterproofing integrity verifications should include testing reports for hydrostatic pressure resistance exceeding 9,800 Pa. Budgetary planning must consider total lifecycle costs; premium models may carry 25-40% higher upfront costs but deliver 300% lifespan extension over budget alternatives.

Technical validation includes requesting independent pressure mapping reports showing less than 32mmHg at critical points (capillary closing pressure threshold). For facilities managing diverse patient populations, modular systems offering interchangeable overlays provide maximum flexibility. Implementation success correlates directly with staff education programs—facilities conducting 3-hour technical training sessions report 82% higher protocol compliance in mattress utilization.

(hospital bed mattress 36 x 80)

FAQS on hospital bed mattress 36 x 80

Q: What are the benefits of a 36" x 80" hospital bed mattress for bed sores?

A: A 36" x 80" hospital bed mattress designed for bed sores features pressure-redistribution foam and alternating airflow technology. These medical-grade materials help reduce friction and shear forces while maintaining proper skin microclimate. Many models include removable waterproof covers for hygiene maintenance.

Q: How does a waterproof hospital bed mattress prevent fluid damage?

A: Waterproof hospital bed mattresses use PVC or polyurethane laminated fabrics with sealed seams. These impermeable barriers block liquids while remaining vapor-permeable for comfort. Antimicrobial treatments often enhance infection control in clinical environments.

Q: Are standard 36x80 hospital mattresses compatible with bed frames?

A: Yes, 36" x 80" mattresses match most institutional bed frames' dimensions. Verify depth requirements (typically 5-8") and check for securement features like mattress retention bars. Some bariatric models may require reinforced frames.

Q: What certifications should waterproof medical mattresses have?

A: Look for FDA 510(k) clearance and ISO 13485 certification. Infection control models often carry NSF/ANSI 49 or UL2999 validation. Flame retardancy should meet CAL TB 117 or BS 7175 standards.

Q: How to clean waterproof hospital bed mattresses properly?

A: Wipe daily with hospital-grade disinfectant wipes (avoid bleach). For deep cleaning, use mild detergent and low-pressure water (<30psi). Always follow manufacturer's instructions for drying and chemical compatibility.

-

Sleep Tracking Mattress Maintenance TipsNewsJul.22,2025

-

Mattress Wave Designs for People with ArthritisNewsJul.22,2025

-

Mattress for Back Pain and Spinal AlignmentNewsJul.22,2025

-

Hypoallergenic Properties of Silicone Gel MattressNewsJul.22,2025

-

How a Gel Memory Foam Mattress Regulates TemperatureNewsJul.22,2025

-

Doctors’ Recommendations on Special Mattress for Back PainNewsJul.22,2025

-

Customizing a Patient Bed Mattress for Specific NeedsNewsJul.22,2025