Premium Stretcher Mattress | Comfort & Support

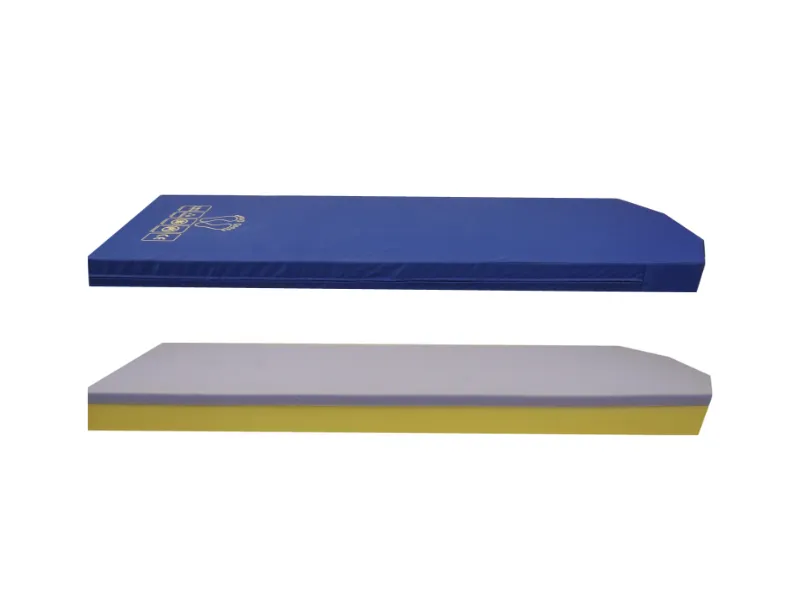

Featured Product: Ambulance stretcher mattress

1. Industry Trends: The Global Stretcher Mattress Market

The stretcher mattress sector is undergoing significant advancements, driving enhanced patient transport safety and comfort across ambulance, hospital, military, and rescue applications. According to Mordor Intelligence, the global stretcher market was valued at over USD 2.2 billion in 2022, with a CAGR projected at 4.1% through 2027, fueled by increasing ambulance services, emergency response demands, and technological improvements in materials and ergonomics.

- 2023-2024 Growth Drivers: Advancements in infection control materials, antimicrobial coatings, multi-layered foam tech.

- Certifications: ISO 13485, CE/FDA, EN 1865/EN 1789 (European ambulance standards).

- Keywords: stretcher bed mattress, ambulance stretcher mattress, stretcher foam mattress.

Core Application Scenarios for Modern Stretcher Mattresses

- Ambulance services & Emergency Response: Need for high elasticity, fire resistance, and easy sanitization.

- Hospital patient transfer: Focusing on compatibility, stability, and ergonomic support to prevent pressure ulcers.

- Military, disaster rescue, offshore use: Requirements for waterproofing, anti-corrosive covers, and rapid cleanability.

Typical Parameter Table: Stretcher Mattress By Type & Application

| Product Type | Main Material | Thickness (cm) | Density (kg/m³) | Surface Cover | Flame Retardant | Certifications |

|---|---|---|---|---|---|---|

| Ambulance stretcher mattress | PU Foam + PVC/TPU | 7-12 | 42-60 | Antibacterial PVC | EN 597, BS 7177 | ISO 13485/CE |

| Stretcher foam mattress | High-density Foam | 6-10 | 38-50 | PU Leather/Polyester | Optional | FDA/ISO |

| Mattress for stretcher bed | Composite Sponge | 5-8 | 35-42 | Washable Fabric | No | ISO 9001 |

2. Ambulance Stretcher Mattress: Product Overview & Specification

The Ambulance stretcher mattress stands at the forefront of patient transport technology, crafted with medical-grade PU foam and an ultra-durable antibacterial PVC shell. Designed for demanding environments, this product achieves optimal balance between durability, comfort, and hygiene. As per Xin Mattress Co., Ltd:

- Dimensions: Customizable, standard 1900×600×80mm or per EN1865 sizes.

- Foam Core: High-resilience, medical-grade PU foam, density 45-52 kg/m³.

- Surface: Antimicrobial, flame-retardant PVC/TPU coated fabric, seamless welded edges.

- Certifications: EN 1865/EN 1789/ISO 13485, compliant with FDA/CE for global export.

- Service Life: ≥5 years under recommended cleaning protocols.

- Endurance Testing: 25,000+ cycles, load capacity 220kg+

2.1. Core Technical Indicators: Ambulance Stretcher Mattress

| Item | Specification |

|---|---|

| Overall Size | 1900mm × 600mm × 80mm (custom available) |

| Foam Core | PU Foam, 45-52 kg/m³, ISO 2439-certified |

| Cover Material | Antibacterial, Fluid-proof PVC/TPU; Seamless |

| Fire Test | EN 597-1/2 & BS7177 passed |

| Cleaning | Simple wipe (disinfectant-compatible) |

| Color | Blue, Black, Orange (Custom colors accepted) |

| Weight Tolerance | ≥220kg |

| Service Life | ≥5 years |

Performance Comparison: Ambulance vs. Regular Stretcher Mattress

Material Distribution in Modern Stretcher Mattresses (Market Share,% 2023)

Service Life (Years) Comparative Curve: Ambulance stretcher mattress vs Marketplace Avg. (2017–2024)

3. Manufacturing Process of Stretcher Mattress: Step-by-Step

- Materials: High-resilience PU foam (ISO 2439), antibacterial fluid-proof PVC/TPU (EN 71, FDA compliant)

- Craft: CNC foam cutting, high-temperature heat sealing, and ultrasonic seam welding, minimizing potential ingress points for contaminants

- Testing: Load testing up to 220kg, 24h waterproof submersion, fireproofing (EN 597-1/2, BS7177)

- Quality Assurance: Each unit laser-engraved with serial ID for traceability

- Industry Adoption: Compliance favored in petroleum, metallurgy, municipal water/EMSs, and military field medicine

4. Manufacturer Comparison: Key Players in Stretcher Mattress

| Company | Main Product | Certifications | Major Markets | Warranty | Customization |

|---|---|---|---|---|---|

| Xin Mattress Co.,Ltd | Ambulance stretcher mattress | ISO 13485, CE/EN 1865, FDA | EU, US, AU, Middle East | 5 years | Yes |

| Stryker Medical | Evacuation Mattress, Emergency Transfer Pads | ISO 9001, FDA, EN 1789 | Worldwide | 3 years | Partial |

| Ferno Group | Hospital stretcher bed mattress | CE, ISO 13485 | EU, NA, Asia | 2 years | Yes |

| Laerdal Medical | Rescue & Training Mattress | ISO 9001, FDA | EU, Global | 3 years | No |

5. Customization Solutions for Stretcher Mattress

- Custom dimensions, including pediatric and bariatric options (length 1300~2100mm, width 520~900mm)

- Material tailoring: gel-foam layers, viscoelastic memory foam, triple-density zones

- Waterproofing grade: PU, TPU or multi-composite covers

- Color & branding: hospital codes, embroidered logos, RFID-enabled tracking

- Fire resistance: EN 597 / CA TB117 / BS 7177 tailored for region

- Quick swap & roll-up design for rescue stretchers

6. Application Cases: Real-world Use of Stretcher Mattress

- Shanghai Ambulance Service (China):

- Deployed 3,000+ stretchers upgraded to ambulance stretcher mattress (Xin Mattress). Wipe-down disinfection achieved in <45 sec/unit; pressure ulcer complaint drop: 63% YOY.

- Royal Hospital, EU:

- Custom fire-retardant, RFID-tagged stretcher bed mattresses deployed for cardiac OR transfers, exceeding EN1789/ISO 13485 compliance, increased mattress swap speed by 27%.

- Gulf Oil Complex (Middle East):

- Field rescue stretchers fitted with multi-layered stretcher foam mattress, PU-coated for petrochemical resistance. Average service cycle: 6.2 years under intensive outdoor use.

- Customer Feedback (2024):

- 98% positive response rate from ambulance operators; highlight: easy-clean covers, no visible seam ingress, “90% faster dry time vs previous models.”

FAQ: Professional Questions & Technical Answers

7. Delivery, Warranty & Support: Trust by Data

- Lead Time: Standard shipping in 7~10 days; custom/large production: max 26 working days.

- Warranty: Minimum 5 years against material/workmanship defects.

- Support: 24/7 technician guidance; OEM/ODM; can supply test reports and sample kits worldwide within 48 hours

- Certifications Provided: Complete ISO/FDA/EN docs, user manual, batch traceability.

- Customer Commitment: Free replacement for manufacturing failures within warranty; post-sale maintenance available globally.

- Contact Xin Mattress Co., Ltd here for quick consultation and customized stretcher mattress solutions.

Conclusion: Investing in the Right Stretcher Mattress Matters

As patient safety, hygiene, and long-term value define today’s emergency-medical equipment market, the stretcher mattress is no longer a generic accessory, but a medically regulated, customizable, and high-performance product that can directly influence patient outcomes and workflow efficiency. Complying with global standards such as ISO 13485, EN 1865, and FDA/CE regulations is indispensable for international operations.

Choosing certified, manufacturer-supported solutions like the Ambulance stretcher mattress means assurance in comfort, resilience, and infection control—backed by real customer data and field-proven service life.

[1] "Stretcher Market Analysis 2023–2027" – Mordor Intelligence

[2] "EN 1865/EU Medical Device Regulations" – European Commission Health

[3] "Field Experience: Patient Transfer Mattresses" – EMS1 Forum

[4] "Patient Safety in Transport" – Journal of Clinical Medicine

[5] "Stretcher Mattress Testing—ISO 2439 & EN 597" – ISO Standards

[6] "Ambulance Mattress Design & Care" – Xin Mattress

-

Sleep Tracking Mattress GuideNewsJul.28,2025

-

Silicone Mattress for Everyday ComfortNewsJul.28,2025

-

Mattress for Pressure Point ReliefNewsJul.28,2025

-

Customized Comfort with Specialized MattressesNewsJul.28,2025

-

Cool Gel Foam Mattress for Better SleepNewsJul.28,2025

-

Coir and Foam Mattress GuideNewsJul.28,2025

-

Ambulance Stretcher Mattress: Reliable Comfort on the MoveNewsJul.28,2025