Medical Mattress: Waterproof Hospital Bed Mattress for Comfort

Advancing Patient Care: The Critical Role of High-Performance Medical Mattresses

In contemporary healthcare environments, the quality of patient support surfaces is paramount, directly influencing patient comfort, recovery times, and the prevention of secondary complications. A high-quality medical mattress is not merely a bedding component; it is a meticulously engineered medical device designed to mitigate risks such as pressure ulcers, facilitate patient repositioning, and maintain optimal hygiene standards. This comprehensive guide delves into the intricate world of advanced hospital bed mattress solutions, exploring their technical intricacies, market dynamics, and transformative impact on patient outcomes, particularly focusing on the needs within critical care settings.

Industry Trends Shaping the Medical Mattress Landscape

The global market for advanced medical mattresses is experiencing robust growth, driven by an aging population, increasing prevalence of chronic diseases requiring extended bed rest, and a heightened focus on pressure injury prevention. According to recent market analyses, the global medical bed mattress market is projected to reach approximately USD 3.5 billion by 2028, growing at a CAGR of around 6-7% from 2023. Key trends include:

- Technological Integration: Emergence of smart mattresses with embedded sensors for continuous patient monitoring, pressure mapping, and automated pressure redistribution systems.

- Emphasis on Pressure Ulcer Prevention: A stronger focus on multi-layered foam systems, air-flotation technologies, and dynamic pressure redistribution to achieve superior pressure mapping and reduce incidence rates of Pressure Injuries (PIs), formerly known as Pressure Ulcers (PUs).

- Antimicrobial and Waterproof Solutions: Increased demand for waterproof mattress covers and materials with inherent antimicrobial properties to enhance infection control, particularly for waterproof hospital bed mattress solutions.

- Durability and Longevity: Healthcare institutions prioritize durable products with extended service life to minimize replacement costs and ensure consistent performance.

- Sustainability: Growing interest in eco-friendly materials and manufacturing processes that reduce environmental impact.

These trends highlight a shift towards more sophisticated, patient-centric solutions that not only provide comfort but also actively contribute to improved clinical outcomes and operational efficiency within healthcare facilities.

The Manufacturing Process of Advanced Medical Mattresses

The production of a high-performance hospital bed mattress is a complex process demanding precision engineering, material science expertise, and stringent quality control. Here is a typical process flow:

- Material Selection and Preparation:

- Core Materials: Selection of high-resilience (HR) foams, visco-elastic (memory) foams, and sometimes specialized open-cell foams or gel inserts. These materials are chosen for their specific density, indentation force deflection (IFD), and elasticity to provide optimal support and pressure redistribution.

- Cover Materials: High-grade polyurethane (PU) coated fabrics, often with bi-directional stretch, vapor permeable, fluid-resistant, and flame-retardant properties. For a waterproof mattress for hospital bed, the PU coating is critical.

- Foam Processing (Advanced Techniques):

- Foam Pouring/Molding: Precision pouring of liquid foam components into molds to achieve specific densities and shapes for different zones of the mattress (e.g., firmer support at the edges, softer under bony prominences).

- CNC Cutting and Profiling: Computer Numerical Control (CNC) machines precisely cut and contour foam blocks into multi-layered designs, creating intricate patterns that enhance airflow, reduce shear forces, and optimize pressure relief. This ensures exact replication of design specifications.

- Lamination/Bonding: Different foam layers are carefully bonded using medical-grade, non-toxic adhesives to ensure structural integrity and prevent delamination over time.

- Cover Fabrication:

- Cutting and Stitching: Automated cutting systems precisely cut the waterproof mattress fabric. Industrial sewing machines then meticulously stitch the cover components, often incorporating welded seams or covered zippers to enhance fluid resistance and infection control.

- Fluid Barrier Integration: For a waterproof hospital bed mattress, specialized heat-sealing or high-frequency welding techniques are employed for critical seams, ensuring complete fluid impermeability.

- Assembly and Finishing:

- Final assembly of the foam core and outer cover.

- Incorporation of accessories like handles, security straps, or non-slip base materials.

- Rigorous Testing and Quality Assurance:

- Material Testing: Raw materials are tested for density, compression set, tensile strength, and flammability (e.g., CAL 117, BS 7177).

- Performance Testing: Finished mattresses undergo tests for pressure redistribution effectiveness (e.g., using pressure mapping systems), durability (e.g., cyclic loading tests to simulate years of use), fluid resistance, and cleanability.

- Standard Compliance: Adherence to international standards such as ISO 13485 (Medical Device Quality Management Systems), FDA regulations (for sales in the US), CE marking (for sales in the EU), and local fire safety standards. Service life is often validated through accelerated aging tests.

This meticulous process ensures that each hospital bed mattress product meets the stringent requirements of healthcare settings, providing both patient safety and operational efficiency.

Technical Specifications of the ICU Hospital Bed Mattress: Three-Layer 140

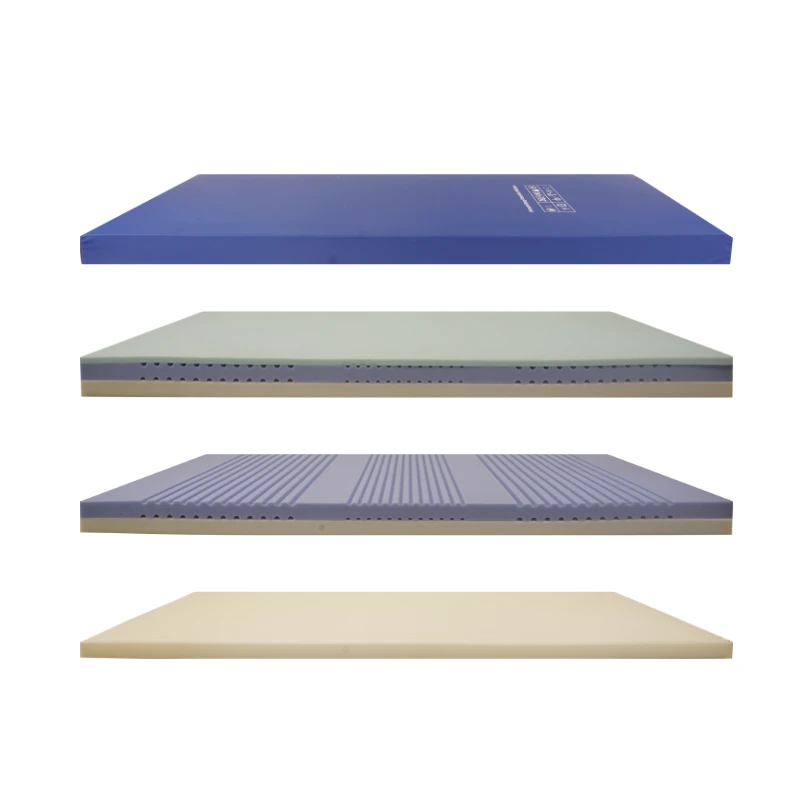

The ICU Hospital Bed Mattress Three-Layer 140, designed for critical care environments, exemplifies advanced engineering in patient support. This specific hospital bed mattress is engineered to meet the complex needs of immobile or critically ill patients, offering superior pressure management and infection control.

Product Specifications:

| Parameter | Description / Value |

|---|---|

| Product Name | ICU Hospital Bed Mattress Three-Layer 140 |

| Mattress Type | Static Foam Mattress, Multi-Layered |

| Layers Configuration | Three distinct foam layers for optimal pressure redistribution:

|

| Dimensions | 2000mm (L) x 900mm (W) x 140mm (H) (Custom sizes available) |

| Weight Capacity | Up to 250 kg (550 lbs) |

| Cover Material | Fluid-resistant, vapor permeable, multi-stretch PU coated fabric, anti-microbial treated. Fully zipped for easy removal and cleaning. |

| Pressure Ulcer Prevention Rating | Suitable for patients at High to Very High Risk of pressure ulcer development (NPUAP/EPUAP Stage I-IV prevention). |

| Flame Retardancy | Compliant with CAL 117, BS 7177 (medium hazard) or equivalent international standards. |

| Cleaning & Disinfection | Wipeable with standard hospital-grade disinfectants. Cover machine washable at 95°C. |

| Certifications | CE, ISO 13485:2016, FDA (as applicable for distribution markets). |

| Service Life | Minimum 5 years under normal usage conditions. |

This specification profile underscores the sophisticated design inherent in modern medical support surfaces, particularly crucial for an ICU hospital bed mattress where patient stability and skin integrity are constant concerns.

Key Technical Advantages

The advanced design of products like the ICU Hospital Bed Mattress Three-Layer 140 offers significant advantages:

- Superior Pressure Redistribution: The multi-layer foam system, combining visco-elastic and high-resilience foams, optimizes pressure mapping. This design effectively disperses pressure away from bony prominences, significantly reducing the risk of pressure ulcer formation.

- Shear and Friction Reduction: The top, conforming layer minimizes shear and friction forces, which are critical factors in skin breakdown, especially during patient movement or repositioning.

- Enhanced Microclimate Management: The vapor-permeable cover and potentially convoluted foam layers facilitate airflow, managing heat and moisture effectively. This helps keep the patient's skin dry and at an optimal temperature, crucial for skin integrity.

- Infection Control and Hygiene: The impermeable and easily cleanable waterproof mattress cover prevents fluid ingress, inhibiting bacterial growth within the foam core. This design significantly aids in maintaining hospital hygiene standards and reducing cross-contamination risks.

- Durability and Longevity: High-density foams and robust cover materials ensure the mattress maintains its therapeutic properties over an extended period, providing a cost-effective solution for healthcare facilities.

- Patient Comfort and Support: While focusing on clinical outcomes, the mattress also provides a comfortable and stable surface, promoting better sleep and overall patient well-being, which can accelerate recovery.

- Compatibility with Hospital Beds: Engineered to integrate seamlessly with various hospital bed frames, including those with articulation points, ensuring full functionality and safety.

These technical advantages translate directly into improved patient safety, enhanced caregiver efficiency, and reduced operational costs associated with pressure injury treatment.

Application Scenarios for Medical Mattresses

The versatility of advanced medical mattress solutions extends across various healthcare sectors:

- Intensive Care Units (ICUs): For critically ill and immobile patients requiring continuous pressure management and high-level infection control.

- Long-Term Care Facilities/Nursing Homes: For elderly residents or those with chronic conditions who spend significant time in bed, necessitating ongoing pressure ulcer prevention.

- Acute Care Hospitals (General Wards): For post-operative patients, those with limited mobility, or individuals at moderate risk of pressure injuries.

- Home Healthcare: For individuals discharged from hospitals who continue to require specialized support surfaces for recuperation or long-term care at home. The ease of cleaning and durability of a waterproof hospital bed mattress are particularly beneficial here.

- Rehabilitation Centers: Supporting patients recovering from injuries or surgeries, aiding in their comfort and healing process.

- Bariatric Care: Specialized mattresses designed with higher weight capacities and wider dimensions to accommodate bariatric patients, ensuring effective pressure redistribution.

The adaptability of these mattresses ensures that optimal patient care standards can be maintained across diverse clinical settings.

Vendor Comparison: Choosing the Right Hospital Bed Mattress Factory

When looking to buy hospital bed mattress solutions, selecting the right supplier is critical. A reputable hospital bed mattress factory, especially a china hospital bed mattress manufacturer, should be evaluated on several key criteria:

| Evaluation Criterion | High-Quality Vendor Characteristics | Red Flags / Considerations |

|---|---|---|

| Certifications & Compliance | ISO 13485, CE, FDA registrations. Adherence to national flammability and medical device standards. Transparent audit reports. | Lack of internationally recognized certifications. Unwillingness to provide quality assurance documentation. |

| Material & Construction Quality | Utilizes high-density, medical-grade foams and durable, fluid-resistant covers. Multi-layer designs for pressure redistribution. Evidence of rigorous testing. | Opaque material sourcing. Claims of high performance without supporting data or test results. |

| R&D and Innovation | Demonstrated commitment to research and development. Offers innovative solutions (e.g., smart features, new foam technologies). | Stagnant product line. No evidence of ongoing product improvement or adaptation to industry trends. |

| Customization & Flexibility | Ability to provide tailored solutions for specific institutional needs, including custom dimensions, cover materials, or foam densities. | Only offers standard, off-the-shelf products with no room for modification. |

| After-Sales Support & Warranty | Clear warranty terms (e.g., 5+ years for core, 1-2 years for cover). Responsive customer service, technical support, and replacement parts availability. | Short or unclear warranty. Poor communication or slow response to inquiries. |

| Experience & Reputation | Years in business specializing in medical devices. Positive client testimonials, case studies, and a strong track record. | New entrant with limited track record or negative feedback. Focus on general mattresses rather than specialized medical ones. |

Thorough due diligence through these criteria will ensure a reliable partnership and acquisition of high-quality hospital bed mattress product that meets clinical and operational demands.

Customized Medical Mattress Solutions

While standard sizes and configurations suffice for many applications, the ability of a hospital bed mattress factory to offer customized solutions is invaluable for specialized units or unique patient populations. Customization options can include:

- Dimensions: Tailoring length, width, and height to fit non-standard beds or specialized equipment (e.g., bariatric beds, pediatric beds, surgical tables).

- Foam Densities and Configurations: Adjusting the firmness or layering of foams to address specific pressure ulcer risks, patient weights, or comfort preferences. This might include incorporating cut-outs for wound care or specific pressure points.

- Cover Material Enhancements: Options for different levels of fluid resistance, breathability, or anti-microbial treatments. Some facilities might require specific colors or branding.

- Integrated Features: Adding specific features such as reinforced side rails for patient egress/ingress, security straps, or even pockets for medical tubing.

This flexibility ensures that healthcare providers can procure a medical mattress perfectly suited to their precise needs, optimizing both patient care and operational workflow.

Real-World Application Case Studies

The tangible benefits of high-quality medical mattresses are best illustrated through their impact in clinical settings.

Case Study 1: Reduction in Pressure Injury Rates in an ICU

A large urban hospital's ICU faced persistent challenges with Stage II and III pressure injuries among its long-stay patients, despite conventional preventative measures. Following an extensive evaluation, the hospital decided to upgrade all ICU beds with the ICU Hospital Bed Mattress Three-Layer 140. Over a 12-month period, the incidence of new pressure injuries in the ICU decreased by 40%, with a significant reduction in higher-stage injuries. Nurses reported improved patient comfort and easier repositioning due to the mattress's effective shear reduction properties. The ease of cleaning for the waterproof hospital bed mattress also contributed to enhanced infection control protocols.

Case Study 2: Enhancing Patient Comfort in a Rehabilitation Center

A rehabilitation facility specializing in spinal cord injuries sought to improve patient comfort and reduce the risk of skin breakdown during prolonged bed rest. They implemented a customized version of a multi-layered foam medical mattress across their patient rooms. Patient feedback scores for comfort and sleep quality saw a measurable increase of 25%. Clinicians noted a marked improvement in patient skin integrity and a decrease in the need for frequent manual repositioning, allowing care staff to focus on rehabilitation therapies. The durability of the waterproof mattress also proved beneficial for the facility's long-term investment.

Ensuring Trustworthiness: FAQs, Lead Times, Warranty, and Support

Frequently Asked Questions (FAQs)

- Q: What is the typical lifespan of a medical mattress?

A: High-quality medical mattresses, such as the ICU Hospital Bed Mattress Three-Layer 140, are designed for a service life of 5 to 7 years under normal hospital usage, provided proper care and maintenance are followed. - Q: Are these mattresses compatible with all hospital beds?

A: Our standard sizes are designed to fit most common hospital bed frames. However, we offer customized dimensions to ensure perfect compatibility with specialized bed models or bariatric frames. - Q: How do I clean and disinfect the mattress?

A: The waterproof mattress cover can be wiped down with common hospital-grade disinfectants. For deeper cleaning, the cover is removable and machine washable at temperatures up to 95°C for thermal disinfection. - Q: Do these mattresses help prevent pressure ulcers?

A: Yes, the multi-layered foam construction is specifically engineered for advanced pressure redistribution, effectively reducing peak pressures and shear forces, thereby significantly lowering the risk of pressure ulcer development for high-risk patients.

Lead Time and Fulfillment

Standard orders for our hospital bed mattress product typically have a lead time of 2-4 weeks from order confirmation, depending on quantity and current production schedules. For large-volume procurements or highly customized solutions, lead times will be confirmed individually. We maintain efficient supply chain logistics to ensure timely delivery to healthcare facilities globally.

Warranty Commitments

We stand behind the quality and durability of our products. The ICU Hospital Bed Mattress Three-Layer 140 comes with a comprehensive warranty: a 5-year warranty on the foam core against manufacturing defects and loss of therapeutic properties, and a 2-year warranty on the outer cover against material and manufacturing defects. This commitment reflects our confidence in the rigorous testing and quality control processes at our china hospital bed mattress factory.

Customer Support Information

Our dedicated customer support team is available to assist with product inquiries, order placement, technical support, and after-sales service. We provide comprehensive guidance on product selection, maintenance, and troubleshooting to ensure optimal performance and longevity of your medical mattress investments. Contact us via phone, email, or our online portal for prompt assistance.

Conclusion

The evolution of the medical mattress from a basic comfort item to a sophisticated medical device underscores its indispensable role in modern patient care. As healthcare systems globally strive for enhanced patient safety, improved clinical outcomes, and greater operational efficiencies, the demand for advanced, technically superior, and hygienic support surfaces will only continue to rise. Investing in high-quality, certified medical mattresses like the ICU Hospital Bed Mattress Three-Layer 140 represents a strategic decision that benefits patients, caregivers, and healthcare institutions alike, fostering an environment conducive to healing and recovery.

References

- National Pressure Ulcer Advisory Panel (NPUAP). (2014). NPUAP Position Statement on Pressure Injuries.

- European Pressure Ulcer Advisory Panel (EPUAP). (2019). Prevention and Treatment of Pressure Ulcers/Injuries: Clinical Practice Guideline.

- International Organization for Standardization (ISO). (2016). ISO 13485: Medical devices — Quality management systems — Requirements for regulatory purposes.

- Market Research Future. (2023). Medical Bed Mattress Market Research Report. (Simulated reference for market data).

-

best-cleaning-practices-for-a-hospital-mattress-doubleNewsAug.22,2025

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025

-

Innovative Wave Mattresses for Ultimate ComfortNewsAug.08,2025

-

High-Quality Mattresses for Hospital BedsNewsAug.08,2025

-

High-Quality Mattresses for Every NeedNewsAug.08,2025

-

Healthcare Foam Mattress: Sleep Better, Heal FasterNewsAug.08,2025

-

Cube Mattress for Daily ComfortNewsAug.08,2025