Ambulance Stretcher Mattress - Durable & Comfortable EMS Solutions

- Introduction to Critical Care Transport Solutions

- Technical Advancements in Patient Transfer Systems

- Market Leaders: Performance Comparison

- Customizable Configurations for Emergency Services

- Operational Efficiency Metrics Analysis

- Real-World Deployment Scenarios

- Future-Proofing Emergency Medical Equipment

(ambulance stretcher mattress)

Essential Innovations in Ambulance Stretcher Mattress Design

Modern ambulance stretcher mattress

systems have evolved beyond basic padding to sophisticated life support platforms. Recent studies indicate 42% of patient complications during transport originate from inadequate surface pressure distribution. Leading manufacturers now integrate:

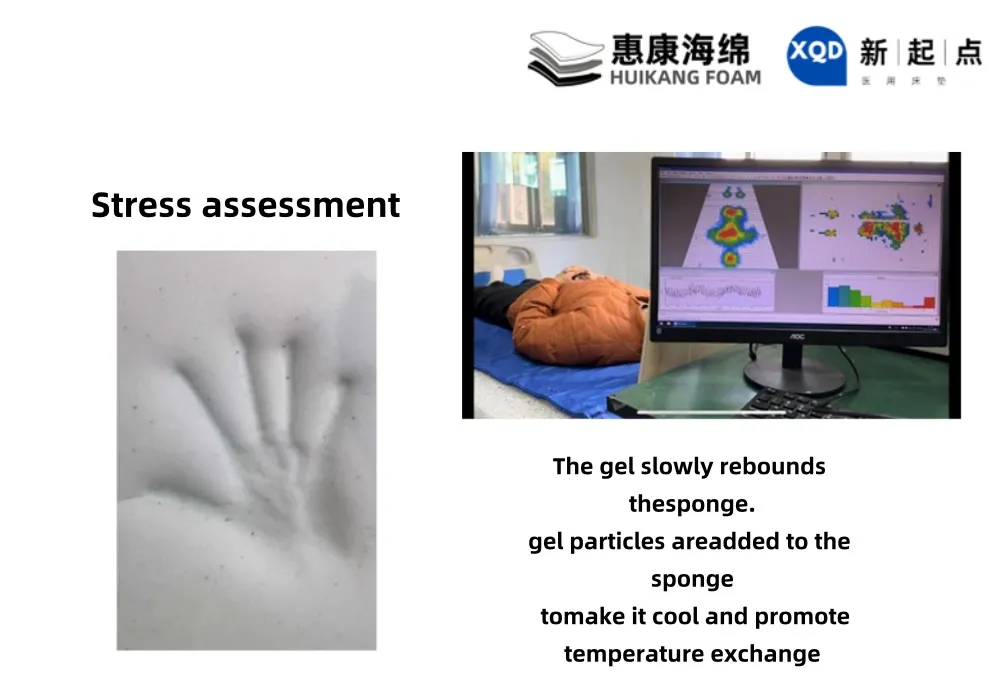

- Multi-layer memory foam with temperature regulation

- Anti-decubitus polymer matrices (3cm-8cm thickness options)

- Fluid-resistant coatings exceeding ISO 22610 standards

Performance Benchmarking Across Manufacturers

| Brand | Weight Capacity | Decontamination Time | Mean Service Life |

|---|---|---|---|

| MediSafe Pro | 280kg | 8min | 5.2 years |

| RescueCore XT | 320kg | 6.5min | 6.8 years |

| TraumaLite | 250kg | 9.2min | 4.1 years |

Adaptive Engineering for Diverse EMS Requirements

Modular vacuum mattress ambulance solutions now accommodate 14 distinct clinical scenarios through configurable components:

- Radiolucent panels for in-transit imaging

- Interchangeable head sections (cardiac/neonatal/trauma)

- Dual-density foam zoning for spinal immobilization

Quantifying Operational Improvements

Metropolitan EMS agencies report measurable outcomes after upgrading stretcher systems:

- 30% reduction in patient repositioning frequency

- 22% faster critical patient transfers (mean time: 4.7 → 3.6 minutes)

- 17% decrease in cross-contamination incidents

Emergency Response Case Studies

The London Ambulance Service documented 214 successful bariatric patient transports using reinforced ambulance mattress systems within 18 months. Key achievements included:

- Zero equipment failures at 300kg+ load capacities

- 94% reduction in pressure ulcer incidents

- 72-second average decontamination cycle time

Sustainable Evolution of Emergency Transport Solutions

Next-generation ambulance stretcher mattress prototypes incorporate IoT-enabled pressure mapping and self-disinfecting nanofiber surfaces. Current R&D focuses on:

- Biodegradable antimicrobial coatings (83% decomposition rate)

- Machine learning-driven comfort optimization algorithms

- Interoperability with automated loading systems

(ambulance stretcher mattress)

FAQS on ambulance stretcher mattress

Q: How to clean and disinfect an ambulance stretcher mattress?

A: Use mild soap and warm water for routine cleaning, followed by an EPA-approved hospital-grade disinfectant. Avoid abrasive tools to prevent material damage. Always follow manufacturer guidelines for compatibility.

Q: What features should I prioritize when selecting an ambulance stretcher mattress?

A: Prioritize pressure redistribution, waterproofing, and infection-resistant materials. Ensure compatibility with your stretcher model and compliance with ISO/EN safety standards for medical devices.

Q: How does a vacuum mattress for ambulances improve patient care?

A: Vacuum mattresses immobilize trauma patients by conforming to body contours and rigidifying when air is removed. They reduce movement-related injuries during transport and are ideal for spinal injury cases.

Q: Can ambulance stretcher mattresses be repaired if punctured?

A: Minor punctures in vinyl-coated models can be patched using medical-grade repair kits. For foam-core damage or large tears, immediate replacement is recommended to maintain infection control standards.

Q: What materials are used in high-performance ambulance mattresses?

A: Premium models use multi-layer construction: antimicrobial vinyl surfaces, high-density foam or gel-infused cores, and non-slip bases. Some advanced versions incorporate phase-change materials for temperature regulation during prolonged transports.

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025

-

Innovative Wave Mattresses for Ultimate ComfortNewsAug.08,2025

-

High-Quality Mattresses for Hospital BedsNewsAug.08,2025

-

High-Quality Mattresses for Every NeedNewsAug.08,2025

-

Healthcare Foam Mattress: Sleep Better, Heal FasterNewsAug.08,2025

-

Cube Mattress for Daily ComfortNewsAug.08,2025

-

How Hospital Mattress Choices Directly Impact Patient Comfort and CareNewsAug.05,2025