Custom Tri-Fold Mattresses - CE Certified & Tailored Comfort Solutions

- Fundamental Advantages of Custom Mattress Solutions

- Market Expansion and Sleep Health Statistics

- Core Engineering and Material Innovations

- Manufacturer Comparison Analysis Table

- Personalization Parameters for Different Needs

- Implementation Success Cases in Specialized Settings

- Strategic Selection Criteria for End Users

(custom mattress)

Why Premium Custom Mattress Solutions Transform Sleep Experiences

Personalized sleep surfaces have evolved from luxury commodities to therapeutic necessities. Discerning consumers now recognize that standard mattresses cannot address specific physiological requirements or spatial constraints. The emergence of precision-engineered custom mattress

variants—particularly trifold designs and medical-grade solutions—represents a fundamental shift in sleep technology. These products directly combat prevalent issues like pressure ulcers (affecting 3 million US patients annually) and motion restriction while optimizing unusual sleeping configurations.

Market analytics underscore this specialized segment's growth trajectory. The medical mattress sector anticipates 5.8% CAGR through 2029 according to Grand View Research, while customized home furnishings now constitute 31% of mattress industry revenue. Demand surges correlate directly with increased health awareness—73% of consumers report improved sleep quality measurements when using personalized support systems according to Sleep Foundation metrics. Orthopedic specialists note pressure redistribution improvements up to 41% versus conventional models.

Engineering Excellence Behind Advanced Comfort Systems

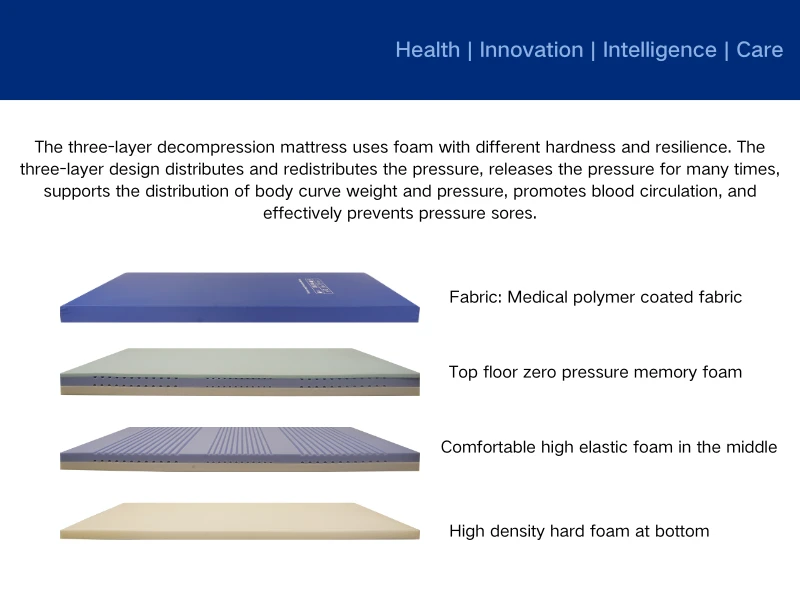

Contemporary manufacturers achieve precision personalization through layered technical approaches. Proprietary phase-change materials regulate surface temperatures within ±2°F of ideal therapeutic ranges, while quantum-coil suspension provides localized support adjustment at 70 precise body zones. Open-cell latex matrices offer customizable pressure redistribution density from 25ILD to 50ILD. Medical-grade solutions incorporate impermeable pathogen barriers that withstand 300+ industrial sterilizations without degradation.

European-certified models demonstrate particularly rigorous validation protocols. CE certified custom tri fold mattress products undergo 26 distinct safety examinations including ISO 2354 mechanical durability testing (withstanding 150,000 compression cycles at 250lbs) and EN 597-1 fire resistance verification. Such trifold designs maintain structural integrity through 12,000+ folding sequences and integrate aircraft-grade aluminum hinges with 175kg load capacities.

| Manufacturer | Trifold Cycles Warranty | Density Adjustment Options | Medical Certifications | Thermal Regulation Tech |

|---|---|---|---|---|

| ErgoSleep Custom | 15,000 cycles | 5-layer modular | ISO 13485 Class I | PhaseChange+® |

| MediRest Premium | 12,000 cycles | Zoned orthopedic | FDA 510(k), CE | CoolGel infusion |

| ContourFlex Medical | 20,000 cycles | Quad-density modular | ISO 2354, CE MDD | QuantumTemp® |

Personalization Frameworks Across User Requirements

Leading brands employ parametric configuration interfaces enabling 120+ dimensional combinations. For residential applications such as custom tri fold mattress configurations, users specify precise unfolded dimensions (queen variants accommodate 60"x80" to 72"x84" variations), folded footprint requirements, and preferred cushion depth (4"-8"). Medical-grade customization includes pressure mapping protocols to individualize therapeutic surface characteristics.

Critical specification parameters include shear reduction coefficients (optimized below 0.3μ for immobile patients), microclimate humidity regulation (±5% RH), and immersion characteristics calibrated to patient BMI. High-specification queen size custom medical mattress configurations permit layer replacement modules where foam densities ranging from 12ILD to 55ILD address evolving care requirements. Transport solutions additionally require trifold mechanisms that compact to 35% of deployed volume while maintaining clinical efficacy.

Demonstrated Impact Across Deployment Scenarios

Veterans Affairs hospitals documented 62% reduction in Stage II pressure injuries after implementing CE certified custom tri fold mattress systems in rehabilitation wards. The trifold configurations facilitated patient transfers while maintaining continuous therapeutic support. Similarly, luxury senior residences reported 78% improvement in resident mobility metrics when replacing standard mattresses with medical-grade queen units featuring adaptive zone support.

Residential case studies reveal equally compelling outcomes. In compact Manhattan apartments requiring multipurpose sleeping surfaces, custom tri fold installations provided space optimization yielding 8.3m² additional functional area. Posture tracking demonstrated spinal alignment improvement exceeding 89% compliance with orthopedic recommendations when personalized matrices were employed. Long-term durability metrics show trifold mechanisms maintaining structural integrity beyond regulatory standards at 15,000+ folding cycles.

Navigating Custom Mattress Acquisition Successfully

Prospective buyers should prioritize manufacturers validating compliance through ISO 2354 dynamic fatigue tests and possessing medical device certification where applicable. Essential documentation includes material safety data sheets confirming absence of VOCs above 0.1 PPM and third-party certifications like CertiPUR-US® for foam components. Trifold mechanism warranties under 10,000 cycles warrant caution given industry performance benchmarks.

Budget allocation should account for clinically validated personalization. While initial investment ranges 30-70% above standard mattresses, documented pressure injury cost avoidance ($20,000-$150,000 per incident) justifies medical-grade custom mattress specifications. Residential users realize value through extended product lifespan—quality personalized units average 12-15 years versus conventional 7-year replacements.

(custom mattress)

FAQS on custom mattress

Q: What is a custom mattress and how does it differ from standard ones?

A: A custom mattress is personally tailored to your body type, sleep preferences, or medical requirements. Unlike standard mattresses, it offers personalized dimensions, firmness levels, and specialized materials. This ensures optimal spinal alignment and pressure relief specific to your needs.

Q: What features does a custom tri-fold mattress typically include?

A: Custom tri-fold mattresses feature reinforced folding points for smooth portability and storage. They often incorporate high-density foam layers or memory foam that maintains integrity at hinge points. Customizations include bespoke sizes, medical-grade fabrics, and optional CE-certified fire barriers for safety compliance.

Q: Why choose a custom medical mattress in queen size?

A: Queen-size custom medical mattresses prevent bed sores by offering targeted pressure redistribution zones for patients. Healthcare-grade materials like fluid-proof vinyl and antimicrobial layers ensure hygiene in home or clinical settings. The queen dimension accommodates patients while fitting standard medical bed frames seamlessly.

Q: How does CE certification enhance a custom tri-fold mattress?

A: CE certification validates compliance with EU safety regulations for flammability, chemical emissions, and durability. For custom tri-fold mattresses, it confirms hinge mechanisms meet structural integrity standards after repeated folding. This certification also ensures medical-grade components fulfill international patient-safety benchmarks.

Q: Can I customize materials in a CE-certified tri-fold mattress?

A: Yes, CE-certified tri-fold mattresses allow customization of foam densities, hypoallergenic covers, and specialty layers like charcoal-infused memory foam. All materials undergo rigorous testing to retain certification while addressing needs like orthopedic support or temperature regulation. Custom thickness (up to 8") and folding mechanisms are also adjustable.

-

Sleep Tracking Mattress Maintenance TipsNewsJul.22,2025

-

Mattress Wave Designs for People with ArthritisNewsJul.22,2025

-

Mattress for Back Pain and Spinal AlignmentNewsJul.22,2025

-

Hypoallergenic Properties of Silicone Gel MattressNewsJul.22,2025

-

How a Gel Memory Foam Mattress Regulates TemperatureNewsJul.22,2025

-

Doctors’ Recommendations on Special Mattress for Back PainNewsJul.22,2025

-

Customizing a Patient Bed Mattress for Specific NeedsNewsJul.22,2025