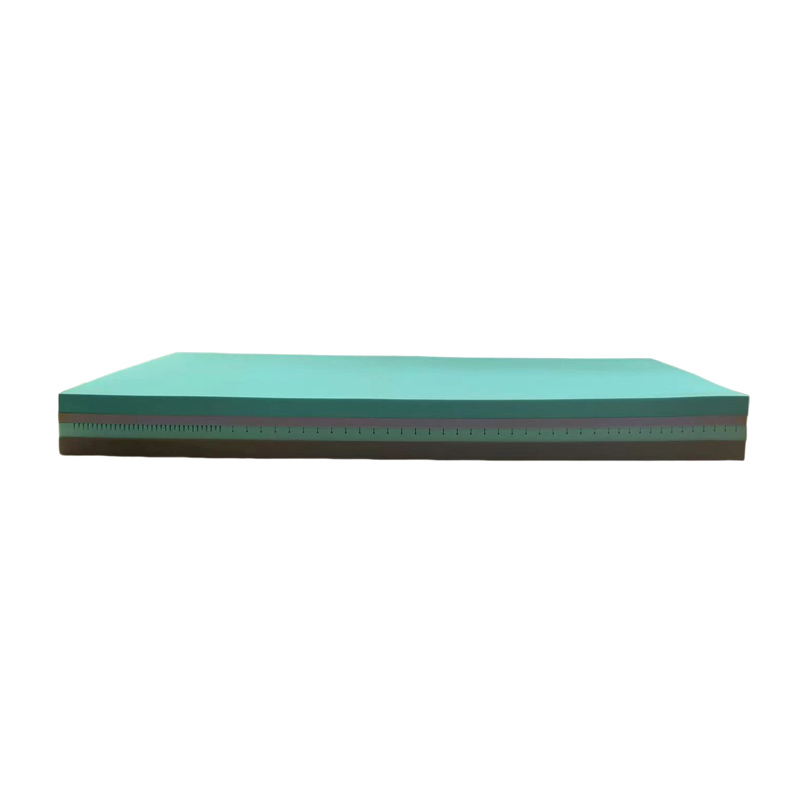

anti pressure sore mattress factory

The Importance of Anti-Pressure Sore Mattresses A Closer Look at Manufacturing Practices

In the realm of healthcare and comfort, the significance of anti-pressure sore mattresses cannot be overstated. These specialized mattresses play a crucial role in preventing pressure sores or bedsores, particularly for individuals who are bedridden or have limited mobility. As a result, the demand for high-quality anti-pressure sore mattresses continues to grow, leading to the emergence of numerous factories dedicated to their manufacturing. This article explores the intricacies of anti-pressure sore mattress production, highlighting the necessary materials, design considerations, and quality assurance practices involved.

Understanding Pressure Sores and Their Impact

Pressure sores are injuries to the skin and underlying tissue that result from prolonged pressure on the skin. They are most commonly found in individuals who are unable to move due to illness or injury. These sores can lead to severe complications, including infections, prolonged hospital stays, and, in extreme cases, life-threatening conditions. The importance of prevention through effective mattress design is thus paramount.

Key Features of Anti-Pressure Sore Mattresses

Anti-pressure sore mattresses are designed with several key features aimed at redistributing body weight, reducing pressure on vulnerable areas, and enhancing overall comfort. The most common types of materials used in these mattresses include memory foam, gel-filled components, and air cell technology.

1. Memory Foam One of the most popular materials, memory foam conforms to the body’s shape, providing support where it is needed most. By reducing pressure points, it minimizes the risk of developing sores.

2. Gel-Infused Layers Gel-filled mattresses help to dissipate body heat, keeping the user cool and comfortable. This cooling effect can significantly enhance comfort for individuals who spend extended periods in bed.

3. Air Cell Technology Some advanced mattresses utilize air bladders that can be adjusted to change the pressure distribution dynamically. This feature allows for optimal comfort and support while effectively preventing the occurrence of pressure sores.

anti pressure sore mattress factory

The Manufacturing Process

The manufacturing of anti-pressure sore mattresses involves meticulous attention to detail and quality control at every step

. Factories typically follow a series of standardized procedures to ensure that each product meets stringent health and safety standards.1. Material Selection It begins with the careful selection of high-quality materials. Manufacturers must source durable, breathable fabrics alongside supportive foam and gel components that comply with medical standards.

2. Design and Engineering Engineers and designers collaborate to create mattress specifications that align with clinical research on pressure sore prevention. This step includes determining the ideal thickness, firmness, and design patterns to effectively distribute weight.

3. Production The production phase involves cutting, shaping, and assembling various materials. Automated machinery is often employed to ensure precision while manual quality checks are performed to maintain high standards.

4. Quality Assurance After production, each mattress undergoes rigorous testing. Factors such as pressure redistribution capabilities, durability, and comfort are assessed to ensure they fulfill the required medical criteria.

5. Packaging and Distribution Finally, the mattresses are carefully packaged to prevent damage during transportation. Factories develop efficient distribution channels to ensure that healthcare facilities can easily access these essential products.

Conclusion

As the aging population and the number of individuals requiring long-term care continue to rise, the importance of anti-pressure sore mattresses will only increase. Factories dedicated to their production play a critical role in the healthcare industry, providing crucial solutions that enhance patient care and comfort. Through innovative design, advanced materials, and stringent quality control, these manufacturers contribute significantly to the overall wellbeing of patients, helping to alleviate the risks associated with pressure sores. The commitment to continuous improvement and research in this field will ensure that healthcare providers have access to the best possible tools to support their patients in their journey toward recovery and comfort.

-

the-truth-about-orthopedic-mattresses-for-sore-back-painNewsAug.23,2025

-

space-saving-benefits-of-a-single-mattress-cubeNewsAug.23,2025

-

eco-friendly-advantages-of-a-silicon-mattressNewsAug.23,2025

-

how-to-fix-sagging-in-a-special-mattressNewsAug.23,2025

-

how-ambulance-stretcher-mattresses-reduce-pressure-injuriesNewsAug.23,2025

-

best-cleaning-practices-for-a-hospital-mattress-doubleNewsAug.22,2025

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025