Premium Stretcher Mattress | Durable Comfort for Medical Use

Understanding Advanced Stretcher Mattress Technologies

In critical medical and emergency care settings, the quality of patient support surfaces is paramount. A high-performance stretcher mattress is not merely a comfort item; it is a vital component directly influencing patient outcomes, caregiver efficiency, and overall operational safety. As healthcare demands evolve, so too must the technology underpinning these essential devices. Modern stretcher mattresses are engineered to address complex challenges such as pressure injury prevention, infection control, rapid patient transfer, and durability in high-stress environments. The industry is witnessing a significant shift towards materials and designs that offer superior pressure redistribution, fluid resistance, and ease of cleaning, directly contributing to enhanced patient safety and reduced healthcare-associated infections (HAIs). Furthermore, the integration of advanced polymers and composite foams allows for mattresses that are not only lighter and more maneuverable but also exceptionally resilient, capable of withstanding the rigors of continuous use across diverse clinical scenarios, from routine patient transport within hospitals to critical care interventions in emergency vehicles.

The design philosophy behind contemporary stretcher mattress solutions emphasizes a delicate balance between patient comfort and functional exigencies. Key trends include the widespread adoption of multi-layered foam constructions, often incorporating high-resilience (HR) foams for foundational support, viscoelastic (memory) foams for contouring and pressure relief, and sometimes gel infusions for temperature regulation. Specialized cover materials, typically polyurethane-coated fabrics, are becoming standard due to their fluid-impervious, anti-microbial, and breathable properties. These materials are crucial for maintaining hygiene and preventing the proliferation of pathogens. Furthermore, advancements in mattress design are now taking into account factors like radiolucency, allowing for seamless imaging procedures without patient transfer, and compatibility with MRI environments, which necessitates non-ferromagnetic components. The goal is to provide a comprehensive patient support solution that minimizes risk, optimizes care delivery, and extends the product lifespan, thereby offering a superior return on investment for healthcare providers who prioritize patient safety and operational efficiency in their procurement decisions.

The Advanced Manufacturing Process of a Stretcher Foam Mattress

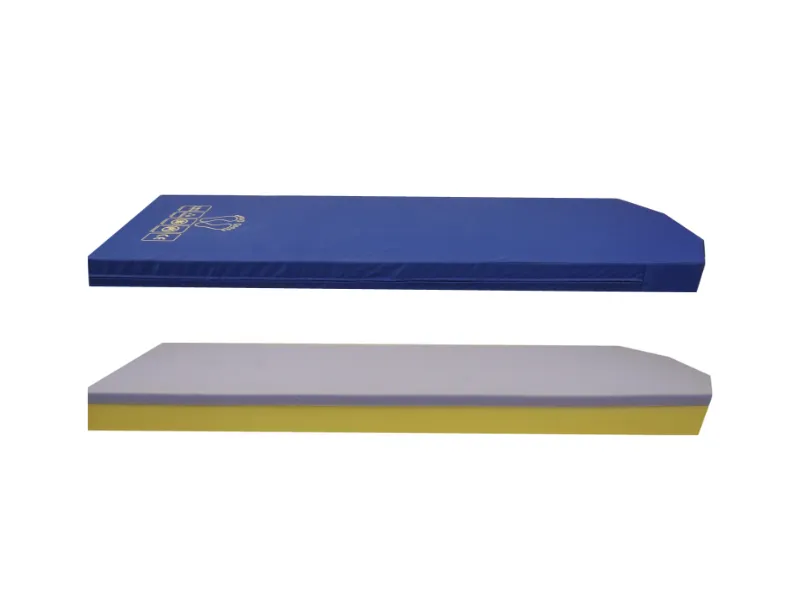

The creation of a high-quality stretcher foam mattress, particularly one designed for an ambulance stretcher mattress application, involves a meticulously engineered manufacturing process that ensures durability, hygiene, and patient comfort under demanding conditions. This sophisticated process begins with the careful selection of raw materials. Typically, this involves sourcing medical-grade, open-cell polyurethane foams, including high-resilience (HR) foams for the core and viscoelastic (memory) foams for the top comfort layers. Cover materials are usually advanced fluid-impervious fabrics, often polyurethane-coated polyesters, known for their anti-microbial properties and ease of cleaning. These materials must meet stringent safety and performance standards, such as those set by ISO 13485 for medical device quality management and various flammability ratings like EN 597-1/2.

Once materials are procured, the process moves to precision foam cutting and shaping. Utilizing computer numerical control (CNC) cutting technology, foam blocks are accurately cut into specific dimensions and contours required for the mattress for stretcher bed, ensuring a perfect fit for various stretcher models. Multi-layer designs, crucial for effective pressure redistribution, involve laminating different foam types together using specialized, non-toxic, medical-grade adhesives. This layering might include a firm base layer for support, a softer middle layer for pressure relief, and a top layer with enhanced comfort characteristics. Following the foam assembly, the cover fabrication begins. This involves precise cutting and industrial sewing or high-frequency welding of the cover material, ensuring robust, sealed seams that prevent fluid ingress and enhance infection control. The final assembly step carefully encloses the foam core within the fabricated cover, often featuring a robust zipper for easy removal and cleaning.

Throughout the entire manufacturing journey, rigorous quality control and testing are paramount. Each stretcher bed mattress undergoes a series of critical inspections. These include dimensional accuracy checks to ensure compliance with stretcher specifications, firmness and indentation load deflection (ILD) tests to verify pressure redistribution properties, and fluid impermeability tests for the cover material. Flammability testing is conducted to ensure compliance with international safety standards. Durability cycling tests, simulating years of use, assess the mattress's long-term resilience and structural integrity, crucial for medical environments where equipment undergoes constant stress. The final product is then packaged in a manner that protects it during transit and maintains its sterile integrity until deployment in various demanding applications such as emergency medical services (EMS), hospital emergency rooms, critical care units, and military field hospitals, where characteristics like lightweight design, superior patient comfort, and robust infection control are non-negotiable advantages.

Technical Specifications and Performance Metrics for Stretcher Mattresses

The performance of a stretcher mattress is quantifiable through a range of technical parameters that directly relate to its efficacy in patient care and operational longevity. Key specifications include dimensions (length, width, height), which must precisely match the stretcher frame to ensure stability and patient safety. Weight capacity is another critical metric, indicating the maximum patient weight the mattress can comfortably and safely support without compromising its pressure-redistributing properties. Material composition details the type and density of foam layers (e.g., high-resilience polyurethane foam, viscoelastic memory foam, gel-infused foam), as well as the specifications of the cover material (e.g., polyurethane-coated fabric, nylon, fluid-impervious, anti-microbial). Flammability ratings, often compliant with standards like EN 597-1/2 or CAL 117, are essential for fire safety in clinical environments.

Beyond basic specifications, advanced metrics for an ambulance stretcher mattress include surface pressure mapping results, demonstrating its ability to distribute patient weight evenly and reduce peak pressure points, thereby mitigating the risk of pressure injuries (bedsores). Vapor permeability (MVTR - Moisture Vapor Transmission Rate) of the cover material is crucial for skin breathability and microclimate management, preventing moisture buildup that can lead to skin breakdown. Ease of cleaning and disinfection protocols are also paramount, often involving materials resistant to common hospital disinfectants and featuring welded or taped seams to prevent fluid penetration. The lifespan of a mattress for stretcher bed is often expressed in durability cycles, representing the number of compressions or transfers it can endure while maintaining its structural and therapeutic integrity. Compatibility with medical imaging equipment, such as X-ray and MRI, is also a growing requirement, necessitating radiolucent and non-ferromagnetic components. These detailed specifications empower healthcare professionals to make informed procurement decisions based on evidence-based performance data.

Comparative Product Specifications: Ambulance Stretcher Mattresses

Applications and Technical Advantages of High-Performance Stretcher Mattresses

The versatility of an advanced stretcher mattress extends across a multitude of critical healthcare and emergency scenarios, each benefiting from its specialized design and robust construction. In hospital emergency departments (EDs), these mattresses are indispensable for rapid patient triage, assessment, and stabilization. Their ability to provide immediate pressure relief is crucial for patients who may remain on a stretcher for extended periods, significantly reducing the risk of pressure injury development during the initial critical hours. In operating rooms (ORs) and recovery areas, they facilitate seamless patient transfers and offer stable support for post-operative recovery. For ambulance and emergency medical services (EMS), the design of an ambulance stretcher mattress is optimized for mobility, impact absorption during transit, and resistance to environmental factors, ensuring patient comfort and safety even in dynamic, challenging conditions.

Beyond conventional hospital use, the application of specialized stretcher bed mattress extends to military field hospitals, disaster relief operations, and remote medical clinics where durability, ease of disinfection, and rapid deployment are paramount. The technical advantages of these mattresses are manifold. Foremost is their superior pressure redistribution capabilities, achieved through multi-layered foam constructions that conform to the patient's body, effectively minimizing areas of high pressure and promoting healthy blood flow. This is a critical factor in preventing pressure ulcers, which are a significant concern in prolonged immobilization. Another key advantage is infection control; most modern stretcher foam mattress products feature fluid-impervious, anti-microbial covers with welded or sealed seams, which can be easily cleaned and disinfected, thereby reducing the risk of cross-contamination and healthcare-associated infections. Furthermore, the robust construction ensures longevity and resistance to punctures, tears, and general wear and tear, even with continuous, heavy-duty use. The inclusion of features like radiolucency allows for X-ray imaging without moving the patient, streamlining workflow and minimizing patient discomfort. These combined advantages underscore their indispensable role in modern healthcare infrastructure.

Choosing the Right Stretcher Mattress: Manufacturer Comparison and Customization

Selecting the optimal stretcher mattress for a specific healthcare environment requires a thorough evaluation of manufacturers and their capabilities, especially concerning customization and support. Reputable manufacturers distinguish themselves not only through product quality but also through adherence to international standards and comprehensive customer service. When comparing providers of stretcher bed mattress solutions, key considerations include their certifications (e.g., ISO 13485, CE, FDA registration), demonstrating compliance with medical device regulations and quality management systems. A manufacturer's research and development capabilities, indicated by their innovation in material science, foam technology, and cover fabric advancements, are crucial for future-proofing your investment. Furthermore, evaluating their service history, customer testimonials, and after-sales support (including warranty and repair services) provides insight into their reliability and commitment to client satisfaction. Companies with a long-standing presence in the medical device market, such as XinMattress with its specialized focus on patient support surfaces, often offer a blend of proven quality and adaptable solutions.

Customization options are increasingly important, especially for facilities with unique requirements or specialized stretchers. A flexible manufacturer can provide tailored dimensions, specific foam compositions (e.g., varying densities, multi-zone pressure relief), or specialized cover materials (e.g., enhanced chemical resistance, radiolucency for imaging departments). For instance, an ambulance stretcher mattress may require specific cut-outs for stretcher mechanisms or a non-slip base for secure transport, which a standard off-the-shelf product might not offer. The ability to consult directly with engineers or product specialists to design a stretcher foam mattress that meets precise functional and environmental specifications is a significant advantage. This ensures that the chosen solution not only fits the physical parameters of the stretcher but also addresses specific patient needs, infection control protocols, and operational workflows. Ultimately, a strategic partnership with a manufacturer capable of delivering both standardized excellence and bespoke solutions guarantees optimal performance and long-term value for healthcare institutions.

Ensuring Trustworthiness: FAQ, Delivery, Warranty, and Support

Frequently Asked Questions (FAQ)

-

Q: How often should a stretcher mattress be replaced?

A: The lifespan of a stretcher mattress depends heavily on its usage frequency and maintenance. Generally, high-quality mattresses designed for medical use have a typical lifespan of 5-7 years, but this can vary. Regular inspections for signs of wear, loss of pressure redistribution properties, or damage to the cover are crucial. Manufacturers often provide durability ratings based on extensive testing, simulating years of use. For example, a mattress that passes 50,000 compression cycles without significant degradation is considered highly durable. -

Q: Are these mattresses compatible with all types of stretchers?

A: While many stretcher bed mattress designs adhere to universal dimensions, it's crucial to verify compatibility with specific stretcher models. Manufacturers like XinMattress offer detailed product specifications and often provide custom sizing options to ensure a perfect fit for diverse stretcher types, including ambulance stretchers, patient transport stretchers, and specialized bariatric stretchers. Always check the dimensions and mounting features required by your stretcher. -

Q: How do these mattresses contribute to infection control?

A: An ambulance stretcher mattress is designed with infection control as a primary concern. They typically feature fluid-impervious, anti-microbial covers that prevent liquid penetration and inhibit bacterial growth. The seams are often welded or taped to eliminate stitching holes where pathogens could harbor. These covers are also easy to clean and disinfect with standard hospital-grade cleaning solutions, significantly reducing the risk of healthcare-associated infections (HAIs) and facilitating efficient turnover between patients.

Delivery and Lead Times

Efficient logistics are vital for healthcare providers. Reputable manufacturers understand the urgency associated with medical equipment procurement. Standard delivery for in-stock stretcher mattress models is typically 7-14 business days, depending on destination and order volume. For customized solutions or large bulk orders, lead times may extend to 3-6 weeks to accommodate specific production requirements and quality assurance protocols. Transparent communication regarding delivery schedules and proactive updates on order status are hallmarks of reliable suppliers, ensuring that healthcare facilities can plan their inventory and operations effectively. Urgent requirements can often be accommodated through expedited shipping options, though this may incur additional costs.

Warranty and Customer Support

A robust warranty and comprehensive customer support are indicative of a manufacturer's confidence in their product and their commitment to client satisfaction. Most high-quality stretcher foam mattress products come with a standard warranty, typically ranging from 1 to 5 years, covering manufacturing defects and material integrity. It is essential to understand the terms of the warranty, including what aspects are covered (e.g., foam core degradation, cover integrity) and the process for submitting claims. Beyond the warranty period, reliable customer support services, including technical assistance, maintenance guidance, and parts replacement, ensure the longevity and continued performance of the investment. Many manufacturers provide dedicated account managers, online resources, and responsive communication channels to address client inquiries and provide timely solutions, fostering long-term partnerships built on trust and reliability.

References

- National Pressure Injury Advisory Panel (NPIAP). Pressure Injury Stages. Available at: npiap.com

- International Organization for Standardization (ISO). ISO 13485: Medical devices — Quality management systems — Requirements for regulatory purposes.

- European Committee for Standardization (CEN). EN 597-1/2: Furniture — Assessment of the ignitability of mattresses and upholstered bed bases.

- U.S. Food and Drug Administration (FDA). Medical Devices. Available at: fda.gov/medical-devices

- Agency for Healthcare Research and Quality (AHRQ). Pressure Ulcer Prevention. Available at: ahrq.gov

-

best-cleaning-practices-for-a-hospital-mattress-doubleNewsAug.22,2025

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025

-

Innovative Wave Mattresses for Ultimate ComfortNewsAug.08,2025

-

High-Quality Mattresses for Hospital BedsNewsAug.08,2025

-

High-Quality Mattresses for Every NeedNewsAug.08,2025

-

Healthcare Foam Mattress: Sleep Better, Heal FasterNewsAug.08,2025

-

Cube Mattress for Daily ComfortNewsAug.08,2025