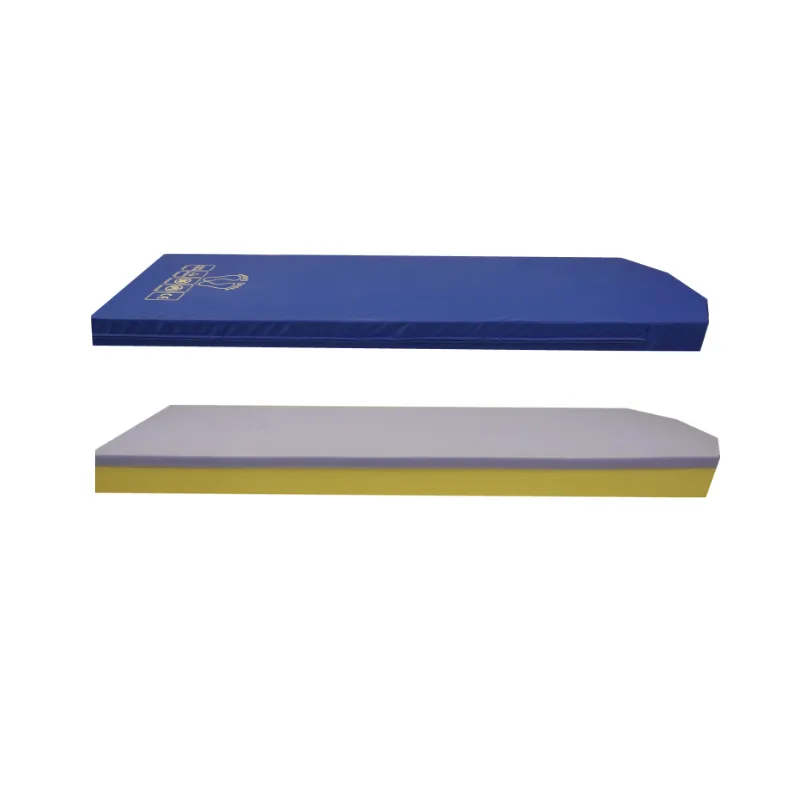

foam custom cut

Custom Foam Cut The Versatile Solution for Multiple Applications

In today’s fast-paced world, customization has become a key demand across various sectors. One area that has gained significant attention is the customization of foam. Foam is an incredibly versatile material, used in a multitude of industries, from automotive to medical, packaging to design. This article will explore the benefits of custom foam cutting and its wide-ranging applications, emphasizing why it is increasingly becoming the go-to solution for businesses and individuals alike.

Understanding Custom Foam Cutting

Custom foam cutting refers to the process of tailoring foam products to meet specific requirements. This procedure involves cutting foam sheets into desired shapes, sizes, and designs using specialized equipment. Whether for protective packaging, cushioning, or artistic projects, the customization process allows for a precise fit, ensuring maximum effectiveness in its intended use.

Benefits of Custom Foam Cutting

1. Precision and Fit One of the significant advantages of custom foam cutting is the ability to achieve an exact fit for your needs. Standard foam products can sometimes be too bulky or not provide the necessary support, leading to wasted space or compromised protection. Customized foam solutions ensure every inch is utilized effectively, offering better performance, especially in protective packaging.

2. Versatility of Materials Foam is available in various types, including polyurethane, polyethylene, and memory foam, each with unique properties suited for specific applications. By choosing custom foam cutting, you can select the material that perfectly aligns with your requirements, whether it’s for enhanced durability, softness, or shock absorption.

foam custom cut

3. Enhanced Protection For businesses that rely heavily on shipping products, custom foam inserts provide a crucial layer of protection against damage during transit. By designing foam packaging that snugly fits around your product, you can reduce the risk of breakage, leading to lower replacement costs and higher customer satisfaction.

4. Cost-Effectiveness While it may seem counterintuitive, investing in custom foam cutting can lead to cost savings in the long run. By minimizing waste and reducing the need for additional packaging materials, businesses can optimize their shipping and manufacturing processes. Additionally, the longevity of high-quality custom foam products reduces the need for frequent replacements.

5. Sustainability As businesses and consumers become more environmentally conscious, custom foam cutting offers sustainable solutions. Many manufacturers now provide eco-friendly foam options made from recycled materials. By opting for customized solutions, you not only enhance your product’s safety but also contribute to a greener planet.

Applications of Custom Foam Cutting

The applications of custom foam cutting are vast and varied. In the medical field, foam is used for ergonomic cushions and supports that enhance patient comfort. In the automotive industry, custom foam components provide sound insulation and crash protection. Retailers utilize foam for effective product displays that attract customers while ensuring the items are securely presented.

Custom foam cutting has also found its place in the technological realm, where devices and equipment require specialized foam inserts for protection during transport. In events and exhibitions, designed foam displays enable products to stand out and be showcased effectively.

In conclusion, custom foam cutting stands as an innovative solution meeting the needs of various industries. With its ability to provide tailored support, enhanced protection, and cost-effectiveness, it is no wonder that businesses are increasingly recognizing its value. Whether for packaging, medical supports, or creative displays, custom foam cuts offer the flexibility and precision demanded in modern applications. If you have specific foam requirements, consider custom solutions to ensure you get the most out of this versatile material.

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025

-

Innovative Wave Mattresses for Ultimate ComfortNewsAug.08,2025

-

High-Quality Mattresses for Hospital BedsNewsAug.08,2025

-

High-Quality Mattresses for Every NeedNewsAug.08,2025

-

Healthcare Foam Mattress: Sleep Better, Heal FasterNewsAug.08,2025

-

Cube Mattress for Daily ComfortNewsAug.08,2025

-

How Hospital Mattress Choices Directly Impact Patient Comfort and CareNewsAug.05,2025