Factory for Durable and Comfortable Protective Mattresses to Ensure Restful Sleep

The Importance of Protective Mattresses An Overview of Factory Production

In the modern world, where comfort, safety, and hygiene are paramount, protective mattresses have emerged as essential elements in many settings, from hospitals to homes. These specialized mattresses play a crucial role in offering both comfort for users and protection for the mattress itself. As consumer demand rises, the role of the protective mattresses factory becomes increasingly significant. This article explores the various aspects of protective mattresses, along with an overview of factory production processes.

Understanding Protective Mattresses

Protective mattresses are designed to safeguard against various factors such as liquid spills, bedsores, allergens, and dust mites. They are often equipped with waterproof covers, antimicrobial treatments, and breathable materials that enhance user comfort while maintaining hygiene standards. These mattresses aren't solely for medical facilities; they are also finding applications in homes, especially for caregivers of elderly or disabled individuals.

Key Features of Protective Mattresses

1. Waterproofing Many protective mattresses incorporate waterproof barriers that prevent liquids from seeping through. This feature is especially beneficial in hospitals and care facilities, where spills are common.

2. Antimicrobial Properties To combat bacteria, fungi, and viruses, factory-produced protective mattresses often feature materials treated with antimicrobial agents. This characteristic helps maintain a clean sleeping environment and reduces the risk of infection.

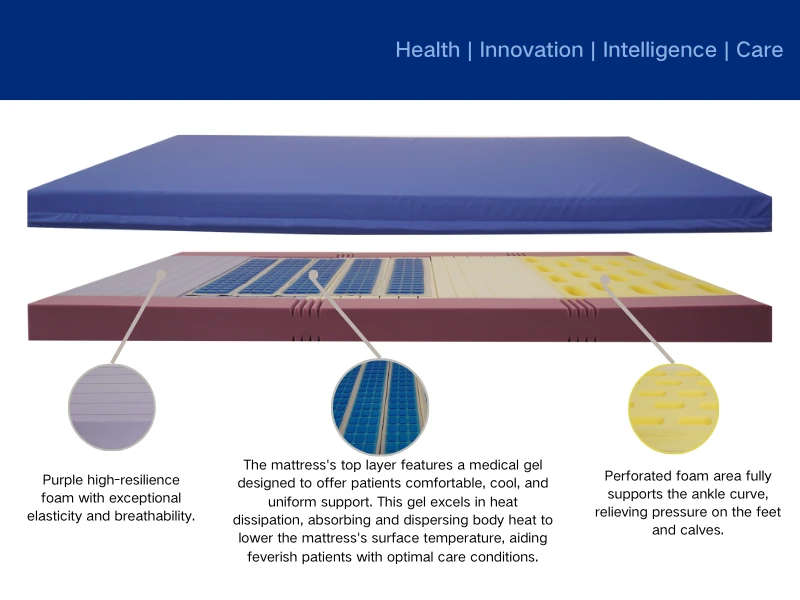

3. Pressure Relief Many specialized mattresses are designed to distribute body weight evenly, which can alleviate pressure points. This feature is crucial for immobile patients, as it can help prevent bedsores.

4. Breathability A good protective mattress must allow for proper air circulation, enhancing comfort and reducing the likelihood of overheating, especially during warmer months.

The Factory Production Process

protective mattresses factory

The production of protective mattresses involves several critical steps, ensuring that the final product meets rigorous quality and safety standards.

1. Material Selection The first step in the manufacturing process is the selection of materials. Factories typically source high-quality fabrics, foams, and other components that meet industry standards for safety and durability. Materials are often chosen based on their waterproof capabilities, durability, and comfort level.

2. Cutting and Shaping After materials are procured, they are cut and shaped according to predetermined specifications. This step involves precise measurements to ensure that the mattress fits standard sizes or specific customer requests.

3. Assembly The next step involves assembling the different layers of the mattress. This usually includes a waterproof layer, cushioning foam, and sometimes specialized pressure-relief materials. Proper assembly is crucial for the mattress's performance and longevity.

4. Quality Control Quality assurance is a vital part of the production process. Each mattress undergoes rigorous testing to check for durability, safety, and comfort levels. Factories often have dedicated teams that inspect mattresses at various stages of production, ensuring that any defects can be caught early on.

5. Packaging and Shipping Once the mattresses have passed inspection, they are packaged for shipment. This step must be handled carefully to prevent damage during transportation. Many factories employ eco-friendly packaging materials to cater to growing consumer concerns about sustainability.

Challenges Faced by Protective Mattress Factories

While the demand for protective mattresses is rising, factories face several challenges. Sourcing sustainable materials, adhering to strict health regulations, and keeping up with technological advancements in mattress manufacturing are just a few hurdles. Moreover, as consumer preferences evolve, factories must be agile, incorporating new features and adapting to market trends to stay competitive.

Conclusion

Protective mattresses are more than just a luxury; they are a necessity in many environments. The factories that produce these mattresses play an essential role in ensuring that consumers have access to safe, comfortable, and hygienic sleeping solutions. With the ongoing advancements in manufacturing technology and a heightened focus on health and safety, the future of protective mattress production looks promising. As the industry continues to evolve, it remains crucial for factories to innovate and adapt to the changing needs of consumers.

-

The Science Behind Silicon Mattresses for Critical Care EnvironmentsNewsJul.16,2025

-

The Role of Wave Mattress Systems in Pressure Ulcer PreventionNewsJul.16,2025

-

The Role of ICU Nursing Silicon Mattress in Preventing Pressure UlcersNewsJul.16,2025

-

Long-Term Bedridden Patients and the Advantages of Silicon Mattresses in the ICUNewsJul.16,2025

-

From ICU to Home Care: Expanding the Use of Silicon Mattresses for Nursing NeedsNewsJul.16,2025

-

Choosing the Right Wave Mattress for Different Levels of Patient CareNewsJul.16,2025

-

The Effect of Coconut Foam Mattress Breathability and Humidity Regulation on Improving Sleep QualityNewsJul.03,2025