professional bedsore prevention mattress mass sales factory

Exploring Professional Bedsore Prevention Mattresses A Factory Perspective on Mass Sales

In the realm of healthcare, the prevention of bedsores—also known as pressure ulcers—remains a critical concern, particularly for individuals with limited mobility or those confined to beds for extended periods. A significant advancement in this field is the development of professional bedsore prevention mattresses, specifically designed to mitigate pressure points and enhance patient comfort. This article delves into the importance of these mattresses, the manufacturing process, and the landscape of mass sales within this niche market.

Understanding Bedsore Prevention Mattresses

Bedsore prevention mattresses play a crucial role in ensuring patient safety and comfort in hospitals, nursing homes, and at home. Bedsore formation occurs when sustained pressure on the skin restricts blood flow, often leading to painful sores. To combat this issue, specialized mattresses utilize various technologies and materials that distribute weight evenly, thus significantly reducing the risk of pressure ulcers.

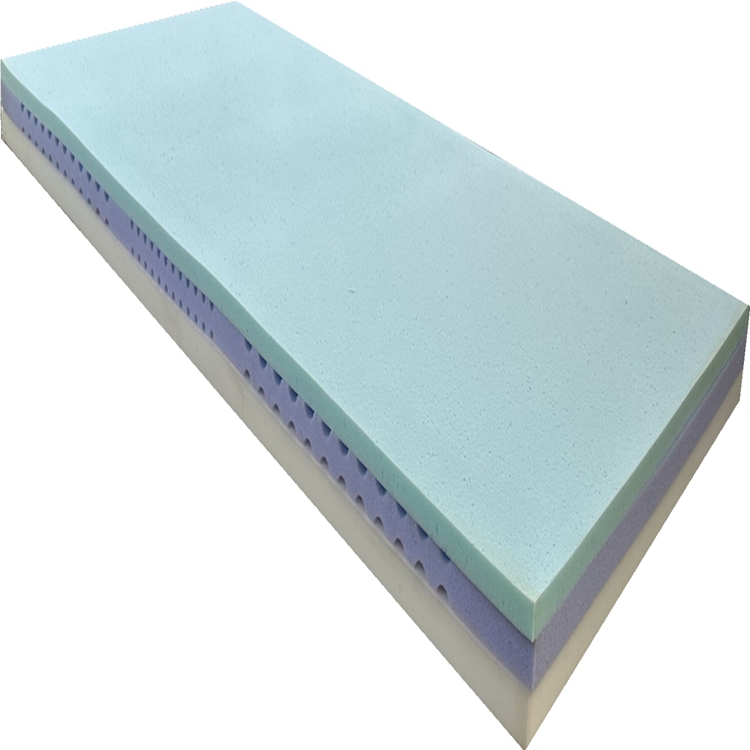

These mattresses often incorporate advanced gel, foam, air, or hybrid technologies that offer unique benefits. For instance, gel mattresses absorb and distribute body heat, helping maintain an optimal temperature for the patient, while air mattresses feature adjustable settings that allow caregivers to customize firmness based on patient needs. Foam mattresses, on the other hand, provide excellent support while also being lightweight and easy to handle.

Manufacturing Process Quality and Innovation

The creation of professional bedsore prevention mattresses involves a meticulous manufacturing process, where innovation and quality control are paramount. Factories specializing in these products invest heavily in research and development to ensure their mattresses meet stringent healthcare standards.

1. Material Selection High-quality materials are essential for durability and effectiveness. Manufacturers assess various foam densities, gel compositions, and air bladder technologies to find the best combination that enhances pressure relief.

2. Design Engineering Ergonomic design is key; the mattress must not only be comfortable but also functional. Engineers work alongside healthcare professionals to develop features that cater to the specific needs of patients at risk for bedsores.

professional bedsore prevention mattress mass sales factory

3. Quality Control Every batch of mattresses undergoes rigorous quality assurance testing. This includes checks for durability, comfort, and pressure redistribution capabilities. Factories utilize sophisticated testing equipment to simulate real-world usage and ensure that products meet or exceed regulatory requirements.

4. Sustainability Practices As environmental concerns grow, many manufacturers are incorporating sustainable practices into their production lines. From sourcing eco-friendly materials to implementing recycling programs, factories are increasingly aware of their ecological impact.

The Landscape of Mass Sales

With an increasing awareness of patient care standards and the importance of bedsore prevention, the market for professional mattresses is expanding rapidly. Hospitals and care facilities recognize the value of investing in high-quality prevention mattresses, not only for patient comfort but also for financial considerations. Preventing bedsores can lead to significant cost savings by reducing the incidence of related complications requiring extensive treatment.

Mass sales strategies encompass various distribution channels, including direct sales to healthcare institutions, partnerships with medical supply companies, and online platforms that allow consumers to access these mattresses directly. Marketing efforts often highlight the scientific backing behind the mattresses’ designs, showcasing their effectiveness in real-world healthcare settings.

Conclusion

As the healthcare landscape evolves, so does the need for innovative solutions to common challenges like bedsores. Professional bedsore prevention mattresses represent a significant step forward in patient care, combining advanced engineering with a keen understanding of patient needs. The manufacturing process, guided by a commitment to quality and sustainability, is crucial in delivering products that can make a real difference in people's lives.

For factories involved in the mass production of these essential healthcare tools, the intersection of technology and compassion drives their mission. As demand grows, the industry must continue to innovate, ensuring that every mattress produced contributes to a safer, more comfortable experience for those at risk of bedsores. With ongoing improvements and increased awareness, the future of bedsore prevention looks promising, paving the way for healthier patient outcomes across the board.

-

The Effect of Coconut Foam Mattress Breathability and Humidity Regulation on Improving Sleep QualityNewsJul.03,2025

-

How Wave Mattress Systems Improve Blood Circulation During ImmobilityNewsJul.03,2025

-

The Climate-Adaptive Sleep Revolution: Exploring the Benefits of Cooling Gel Memory Foam MattressesNewsJul.03,2025

-

Exploration of the Role of Coconut Foam Mattress in Preventing Bedsores in the ElderlyNewsJul.03,2025

-

Comparing Wave Mattress and Air Mattress: Which Is Better for Medical Use?NewsJul.03,2025

-

Analysis of Comfort and Environmental Performance of Natural Latex and Coconut Foam MattressNewsJul.03,2025

-

Multi-Layer Construction for Enhanced Performance in Gel Mattress PadNewsJun.24,2025