Pressure Injury Solutions and Manufacturer Insights for Optimal Patient Care

Understanding Pressure Injury Prevention A Guide for Manufacturers

Pressure injuries, also known as pressure ulcers or bedsores, are a significant concern in healthcare settings, particularly for patients with limited mobility. As a manufacturer, understanding the dynamics of pressure injuries and how your products can contribute to their prevention is essential.

What Are Pressure Injuries?

Pressure injuries result from prolonged pressure on the skin, often over bony areas such as the heels, sacrum, or elbows. They can occur in any patient, but those with limited mobility, poor circulation, or compromised health conditions are at higher risk. These injuries can lead to severe complications, including infections, prolonged hospitalization, and increased healthcare costs.

The Role of Manufacturers in Prevention

Manufacturers play a pivotal role in developing products that can help prevent pressure injuries. This involves not just the creation of specialized mattresses and cushions, but also integrating advanced technologies and materials that enhance patient care.

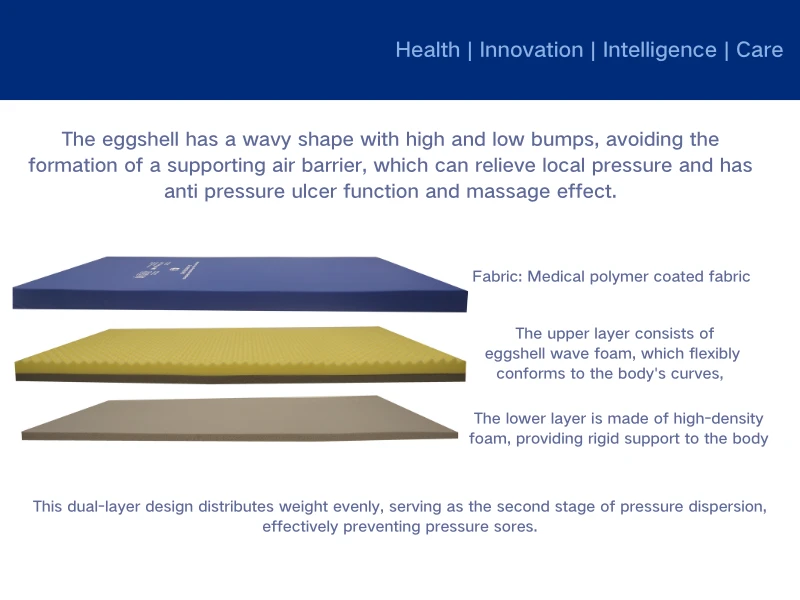

Using advanced materials that promote airflow and moisture management is crucial. Products made from breathable fabrics can help keep the skin dry, reducing the risk of moisture-associated skin damage (MASD). Additionally, materials that offer better pressure redistribution can minimize the localized pressure that leads to skin breakdown.

2. Dynamic Support Surfaces

Dynamic support surfaces, such as air-filled or alternating-pressure mattresses, significantly reduce the risk of pressure injuries. These products work by periodically redistributing weight, thereby alleviating pressure points. Manufacturers need to focus on creating devices that are easy to use while providing effective therapeutic support.

pressure injury manufacturer

3. Monitoring Systems

Integrating monitoring technology into pressure injury prevention products can offer real-time data for caregivers. For instance, smart beds equipped with sensors can alert staff when a patient is at risk of developing a pressure injury, allowing for timely interventions. Additionally, apps or digital platforms that track patient positioning and mobility can provide caregivers with the information they need to prevent injuries proactively.

Collaborating with Healthcare Professionals

To develop effective products, manufacturers must collaborate with healthcare professionals. This partnership helps in understanding the actual challenges faced in clinical settings, leading to more practical solutions. Feedback from nurses, doctors, and therapists can guide product design, ensuring that they meet the needs of patients and caregivers alike.

Education and Training

Another critical aspect of pressure injury prevention is education. Manufacturers should provide training resources for healthcare staff on the proper use of their products. This may include instructional videos, informational brochures, or hands-on workshops. By educating users on how to maximize the benefits of their products, manufacturers can play a vital role in preventing pressure injuries.

Compliance with Standards

Ensuring compliance with healthcare standards and regulations is paramount in manufacturing products for pressure injury prevention. Adhering to guidelines set forth by organizations such as the National Pressure Injury Advisory Panel (NPIAP) can help maintain product efficacy and safety. By staying abreast of these guidelines, manufacturers can ensure that their offerings are not only effective but also endorsed by the wider healthcare community.

Conclusion

In conclusion, addressing pressure injuries is a multifaceted challenge that requires commitment from manufacturers in the healthcare sector. By creating innovative products, leveraging technology, collaborating with healthcare professionals, and providing thorough education, manufacturers can significantly contribute to the prevention of pressure injuries. This not only enhances patient care but also supports the overall mission to improve health outcomes in vulnerable populations. As we move forward, it is crucial for manufacturers to remain engaged and responsive to the evolving needs of the healthcare community, ultimately leading to better protection for patients at risk of pressure injuries.

-

The Effect of Coconut Foam Mattress Breathability and Humidity Regulation on Improving Sleep QualityNewsJul.03,2025

-

How Wave Mattress Systems Improve Blood Circulation During ImmobilityNewsJul.03,2025

-

The Climate-Adaptive Sleep Revolution: Exploring the Benefits of Cooling Gel Memory Foam MattressesNewsJul.03,2025

-

Exploration of the Role of Coconut Foam Mattress in Preventing Bedsores in the ElderlyNewsJul.03,2025

-

Comparing Wave Mattress and Air Mattress: Which Is Better for Medical Use?NewsJul.03,2025

-

Analysis of Comfort and Environmental Performance of Natural Latex and Coconut Foam MattressNewsJul.03,2025

-

Multi-Layer Construction for Enhanced Performance in Gel Mattress PadNewsJun.24,2025