Premium Medical Mattress: Waterproof, Grade for Home & Hospital

In the evolving landscape of healthcare, the importance of patient comfort, safety, and recovery cannot be overstated. At the core of this patient-centric approach lies the sophisticated technology of the medical mattress. Far beyond conventional bedding, these specialized mattresses are engineered to address complex challenges in patient care, from preventing pressure injuries to facilitating healing and ensuring hygienic environments. As a leading expert in providing specialized solutions like our Special Supply Medical Mattresses, we delve into the critical aspects of this essential medical device.

Industry Trends and the Growing Need for Advanced Medical Mattress Solutions

The global healthcare industry is witnessing significant shifts, driven by an aging population, rising chronic disease prevalence, and a heightened focus on quality of life. These factors underscore the increasing demand for advanced medical mattress solutions. Key trends include:

- Pressure Injury Prevention: With an estimated 2.5 million patients developing pressure injuries annually in the U.S. healthcare facilities, costing billions, the drive for effective pressure redistribution mattresses is paramount. Data from the Agency for Healthcare Research and Quality (AHRQ) indicates that hospital-acquired pressure ulcers are a significant quality indicator, pushing institutions to invest in superior support surfaces. This directly impacts medical care quality and cost.

- Infection Control & Hygiene: The COVID-19 pandemic amplified the need for robust infection control measures. Waterproof mattress covers and easily cleanable surfaces have become non-negotiable standards, particularly for waterproof mattress for hospital bed applications, ensuring a sterile environment.

- Home Healthcare Expansion: A growing trend towards home medical mattress use reflects the shift from acute care to community and home-based settings. Patients recovering at home require similar levels of support and comfort, making specialized mattresses crucial for continuity of medical care.

- Smart Technology Integration: The advent of IoT (Internet of Things) in healthcare is leading to medical mattress designs that can monitor patient vitals, detect movement, and even adjust firmness automatically to prevent pressure points. These intelligent systems aim to further optimize patient comfort and preventive care, positioning them as the best medical mattress options for the future.

- Sustainability: Increasing awareness of environmental impact drives demand for mattresses made from sustainable materials and manufacturing processes with reduced waste. Manufacturers are exploring eco-friendly foams and recyclable components to reduce the carbon footprint of healthcare products.

Technical Parameters Defining a Medical Grade Mattress

A truly effective medical mattress is characterized by a precise combination of technical parameters, each contributing to patient well-being and clinical efficacy. Here are key specifications to consider:

Key Medical Mattress Performance Metrics

| Parameter | Description | Typical Range/Standard | Benefit to Patient/Caregiver |

|---|---|---|---|

| Pressure Redistribution (mmHg) | Ability to distribute body weight evenly across the support surface, reducing peak pressure points on vulnerable areas of the body. Often measured by interface pressure mapping (IPM). | <32 mmHg at bony prominences (e.g., sacrum, heels) according to National Pressure Injury Advisory Panel (NPIAP) guidelines. Lower values indicate better redistribution. | Crucial for preventing and treating pressure injuries (bedsores), a primary concern in long-term immobility. Essential for selecting the best medical mattress. |

| Density (Foam, lbs/ft³) | Weight per cubic foot of foam, indicating the amount of material in the foam. Higher density generally means better quality, durability, and support consistency. | 1.8 - 2.5 lbs/ft³ for conventional support layers; 2.5 - 5.0 lbs/ft³ for viscoelastic (memory) foam or gel-infused layers. | Ensures longer product lifespan, consistent therapeutic support over time, and resistance to "bottoming out" (where the patient sinks through comfort layers to the base). |

| Indentation Force Deflection (IFD) / ILD (lbs) | Measures the firmness or softness of foam. It's the force required to indent a 4-inch thick, 50-square-inch foam sample by 25% of its original height. | 15-30 lbs for soft comfort layers; 35-60 lbs for firm support layers. | Allows for precise tuning of the mattress feel and support level, optimizing comfort and pressure relief tailored to patient weight and medical condition. |

| Shear Reduction (Coefficient of Friction) | Minimizes forces that occur when skin remains stationary while underlying tissue shifts, particularly during bed adjustments or patient repositioning. This is often achieved through low-friction top layers and bi-elastic covers. | Low coefficient of friction, often indicated by the fabric's stretch and recovery properties (e.g., 2-way or 4-way stretch). | Significantly reduces the risk of skin breakdown, blistering, and tearing, which can lead to pressure injuries, especially important for elderly or fragile skin. |

| Moisture Vapor Permeability (MVP) (g/m²/24h) | Ability of the cover material to allow moisture vapor (perspiration) to pass through, keeping the patient's skin dry and preventing maceration. | Typically >500 g/m²/24h, measured by ASTM E96 standard. Essential for a waterproof mattress that also breathes. | Maintains a healthy microclimate for the skin, reducing the risk of skin breakdown and promoting overall patient comfort. |

| Fluid Resistance / Waterproofness (Hydrostatic Head, cm H₂O) | Ability of the mattress cover to prevent liquid penetration into the foam core. Measured by the amount of water pressure the fabric can withstand before leakage. | >100 cm H₂O. Must meet standards like AAMI PB70 (Level 4 for surgical drapes/gowns) or ISO 811. Mandatory for any effective waterproof mattress. | Crucial for infection control, enabling easy cleaning and disinfection, and extending the overall life of the mattress by protecting the core. |

| Fire Retardancy (Various Standards) | Resistance to ignition and spread of flame, adhering to national and international safety standards. | Meets CAL 117 (California Technical Bulletin 117), 16 CFR 1633 (U.S. federal standard), BS 7177 (EU standard for contract bedding), or NFPA 701. | Ensures paramount patient safety and compliance with institutional safety regulations, critical in all healthcare settings. |

| Weight Capacity (lbs/kg) | Maximum patient weight the mattress can safely support without compromising its therapeutic performance or structural integrity. | Standard: 300-500 lbs (136-227 kg); Bariatric: 600-1000+ lbs (272-454+ kg). | Ensures effective support, pressure redistribution, and durability for all patient sizes, from pediatric to bariatric. |

| Infection Control Features | Incorporates materials and design elements that inhibit microbial growth and facilitate thorough cleaning. | Antimicrobial treatments (e.g., ISO 22196 for antibacterial activity), seamless or welded designs, bleach-cleanable and fluid-proof materials. | Significantly reduces the risk of cross-contamination, healthcare-associated infections (HAIs), and maintains a hygienic environment for patients and staff. |

Application Scenarios of Special Supply Medical Mattresses

Our Special Supply Medical Mattresses are designed to excel across a diverse range of healthcare environments, providing optimal support and hygiene where it matters most:

- Hospitals (General Wards & ICU): Critical for patients with limited mobility, post-operative recovery, or those at high risk of pressure injuries. The superior pressure redistribution and infection control capabilities reduce hospital-acquired conditions and improve patient outcomes, making them an indispensable component of modern medical care.

- Long-Term Care Facilities / Nursing Homes: Many residents have chronic conditions or age-related mobility issues, making them highly susceptible to skin breakdown. A high-quality medical mattress significantly enhances their comfort, dignity, and quality of life, simultaneously easing the burden of care for staff by reducing the incidence of pressure injuries.

- Home Healthcare Settings: As more care shifts to the home, home medical mattress options provide hospital-grade care in a familiar environment, aiding recovery and independence. Features like portability, ease of setup, and simplified maintenance are crucial here to support the patient and their caregivers.

- Rehabilitation Centers: Patients undergoing physical therapy or recovering from injuries benefit from mattresses that support proper spinal alignment, facilitate easier transfers (e.g., in and out of bed), and provide consistent support during prolonged periods of rest, contributing to faster and more effective rehabilitation.

- Hospice Care: For end-of-life care, comfort and pain management are paramount. These mattresses provide gentle, conforming support, minimize discomfort from pressure points, and help manage pain, ensuring the highest level of dignity and peace for patients.

- Specialty Clinics: Such as burn units, where delicate skin requires extreme care and specialized support surfaces to minimize friction and pressure, promoting healing and preventing further injury. Similarly, for orthopedic recovery, precise support can aid alignment.

Unveiling the Manufacturing Process of Special Supply Medical Mattresses

The creation of a high-quality medical mattress is a meticulous process, combining advanced material science with precision engineering. Our commitment to excellence ensures every Special Supply Medical Mattress meets the stringent demands of modern medical care. While traditional industrial manufacturing often involves processes like casting or forging for metal components, mattress production focuses on sophisticated foam chemistry, advanced cutting techniques, and durable assembly methods.

Detailed Manufacturing Workflow:

Material Sourcing & Quality Inspection

Our process begins with the careful sourcing of premium-grade raw materials. This primarily includes various densities of high-resilience (HR) foams, viscoelastic (memory) foams, and gel-infused foams known for their pressure redistribution properties. For the covers, we utilize durable, multi-stretch, bi-elastic waterproof mattress fabrics, typically polyurethane-coated nylon or vinyl, renowned for their fluid resistance and cleanability. All incoming materials undergo rigorous quality checks, including assessments for density, IFD, flame retardancy, and adherence to biocompatibility standards like ISO 10993, ensuring they are safe for patient contact.

Foam Core Fabrication & Layering

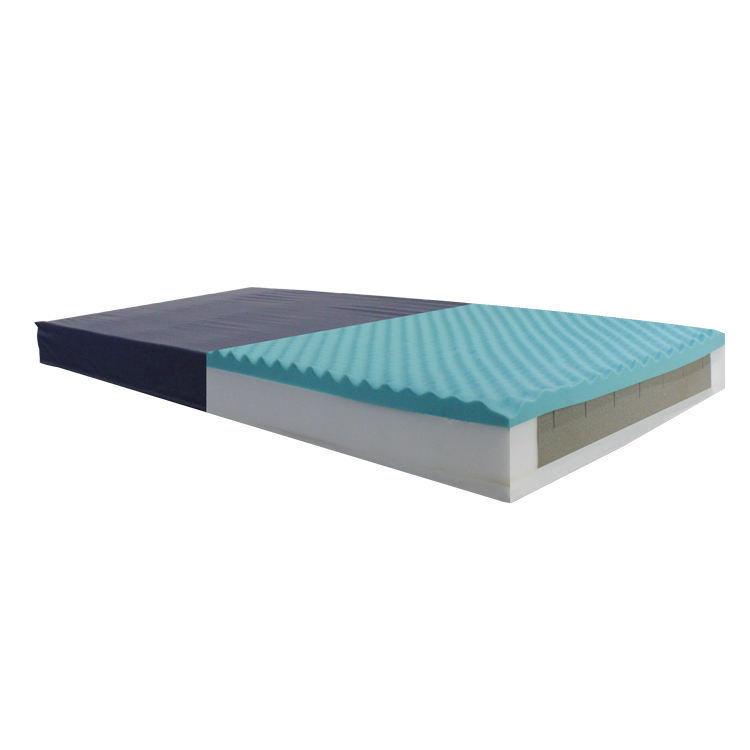

Depending on the specific mattress design (e.g., multi-layered pressure redistribution systems, zoned mattresses), large foam blocks are precisely cut into various shapes and sizes using advanced CNC (Computer Numerical Control) cutting machines. This allows for intricate contours, channels for air circulation, and specialized pressure relief zones (e.g., heel slope, head and foot sections). Different foam densities and types are then expertly laminated together using specialized, non-toxic, water-based adhesives. This precise layering optimizes support, comfort, and therapeutic effectiveness, creating the robust core of our medical grade mattress.

Cover Manufacturing & Sealing

The specialized waterproof mattress covers are cut from large rolls of fabric with precision. To ensure optimal fluid resistance and meet stringent infection control standards, seams are often created using high-frequency welding (RF welding) or ultrasonic welding rather than traditional stitching. This advanced technique eliminates needle holes, creating a hermetic, impenetrable seal that prevents fluid ingress and microbial colonization within the mattress core. This is a hallmark of a truly famous waterproof mattress and critical for hygiene.

Assembly & Final Inspection

Once the foam core is complete and the cover is fabricated, skilled technicians meticulously insert the foam core into its sealed cover. This step requires precision to ensure a snug fit and proper alignment of all therapeutic zones. Each completed medical mattress then undergoes a comprehensive final inspection. This includes visual checks for defects, verification of dimensions, and functional tests such as zipper integrity (if applicable), seam integrity, and fluid resistance spot checks to ensure every product meets our rigorous quality benchmarks before packaging.

Testing & Certification

Before leaving our facility, batch samples of our Special Supply Medical Mattresses are subjected to stringent internal and third-party testing protocols. These include pressure mapping for pressure redistribution efficacy, durability tests (e.g., rolling indent test simulating years of use), fire retardancy tests (e.g., Cal 117, 16 CFR 1633), and fluid resistance tests (e.g., AAMI PB70). Our products consistently meet or exceed international standards like ISO 13485 (Medical Devices Quality Management System) and often carry FDA registration where applicable. This rigorous testing ensures that every medical grade mattress we produce is reliable, safe, and performs optimally in demanding healthcare environments.

Product Material & Craftsmanship: Our Special Supply Medical Mattresses typically utilize a multi-layered design. The foundational layer is often a high-density, firm foam providing stable support and preventing bottoming out. Intermediate layers might include medium-firm foams with sculpted channels for air circulation and additional pressure relief. The top layer, crucial for patient comfort and skin integrity, frequently features visco-elastic (memory) foam or gel-infused foam that gently conforms to the body, distributing pressure uniformly and reducing shear forces. The outer cover is crafted from a famous waterproof mattress material: a bi-elastic, vapor-permeable polyurethane-coated fabric that is not only resistant to fluids but also fire retardant and exceptionally easy to disinfect. This robust construction, combined with meticulous assembly and welding techniques, ensures a long service life, typically 5-7 years under normal medical usage conditions, even in high-traffic hospital settings.

Technical Advantages of Our Special Supply Medical Mattresses

Our Special Supply Medical Mattresses are engineered with distinct advantages, setting them apart in the market and directly addressing critical needs in medical care:

- Superior Pressure Redistribution: Through advanced foam layering, strategic zoning, and the use of high-quality viscoelastic materials, our mattresses effectively reduce interface pressure on bony prominences. This significantly lowers the incidence of pressure injuries, leading to fewer patient complications, reduced treatment costs, and vastly improved patient comfort and recovery times.

- Enhanced Infection Control: Our fully sealed, waterproof mattress covers, often manufactured with welded seams and integrated antimicrobial treatments, prevent fluid penetration and inhibit bacterial proliferation. This ease of cleaning and disinfection is absolutely vital in maintaining stringent hospital hygiene standards and preventing healthcare-associated infections (HAIs), especially for a waterproof mattress for hospital bed.

- Durability and Longevity: Constructed with high-density, resilient foams and robust, tear-resistant covers, our mattresses are designed to withstand the demanding, high-usage environment of healthcare facilities. They resist sagging, cracking, and fluid damage, ensuring a longer medical mattress lifespan and a superior return on investment for healthcare providers, minimizing replacement costs.

- Patient Comfort & Breathability: While waterproof mattress features are critical, breathability is equally important for skin integrity. Our covers are vapor-permeable, allowing heat and moisture (perspiration) to escape efficiently. This prevents skin maceration and enhances overall patient comfort, even during extended periods of immobility, contributing to a healthier skin microclimate.

- Safety Compliance: All our mattresses are meticulously tested and certified to meet or exceed the most stringent fire safety standards (e.g., CAL 117, 16 CFR 1633) and flammability requirements. This provides peace of mind for both patients and healthcare providers, knowing that safety is a top priority in their support surfaces.

- Reduced Shear & Friction: The bi-elastic (multi-directional stretch) properties of our mattress covers minimize shear and friction forces on the patient's skin. This is a critical factor in preventing skin breakdown, particularly when patients are repositioned or when the bed's articulating features are utilized, ensuring maximum skin integrity.

Manufacturer Comparison: Why Xinmattress Stands Out in the Medical Mattress Market

When selecting a medical mattress provider, reputation, expertise, and a steadfast commitment to quality are paramount. While numerous manufacturers exist in the global market, Xinmattress distinguishes itself through several key differentiators that ensure superior product performance and customer satisfaction:

- Specialized Expertise & Focus: With over 15 years of dedicated experience in the mattress industry, Xinmattress has invested significant resources into research and development specifically within the medical mattress sector. Our focus isn't merely on manufacturing general bedding; it's on engineering advanced support surfaces that deliver measurable therapeutic outcomes and improve patient recovery. This deep specialization translates into products perfectly tailored for demanding healthcare environments.

- Uncompromising Quality & Certifications: We are proud to hold internationally recognized certifications, including ISO 9001 (Quality Management System) and ISO 13485 (Medical Devices Quality Management System). These certifications are not just badges; they represent our unwavering commitment to consistent quality, rigorous testing, and strict regulatory compliance for medical devices. Our products frequently meet or exceed FDA (Food and Drug Administration) requirements for medical devices in various markets and carry CE Marking for the European Union, guaranteeing a true medical grade mattress.

- Exceptional Customization Capabilities: Unlike many general manufacturers, we excel in providing custom waterproof mattress solutions. This unparalleled flexibility allows us to precisely meet unique specifications for specialized patient populations (e.g., bariatric), non-standard bed frames, or specific institutional needs, ensuring a perfect fit and optimized performance for diverse clinical requirements.

- Comprehensive Pre- and Post-Sales Support: Our commitment extends far beyond the manufacturing floor. We offer extensive pre-sales consultation to help clients identify the ideal solutions for their specific needs. Post-sales, we provide robust support, including clear warranty services, detailed guidance on proper maintenance and care, and responsive technical assistance, enhancing the overall client experience and ensuring long-term product satisfaction.

- Proven Track Record & Client Success: Our medical mattress solutions have been successfully adopted by numerous prestigious hospitals, long-term care facilities, and home care providers globally. We boast a strong record of positive client feedback, demonstrated improvements in patient outcomes (e.g., reduced pressure injury rates), and long-standing partnerships built on trust and reliability.

"Choosing Xinmattress for our hospital's bed upgrades was a strategic decision rooted in their proven quality, deep understanding of patient needs, and exceptional customer service. Their medical grade mattress solutions have significantly contributed to reducing our pressure injury rates, and their team was incredibly supportive and professional throughout the entire procurement and implementation process. This partnership has genuinely elevated our standard of patient care."

- Dr. Elena Rodriguez, Head of Nursing, City General HospitalCustomization Solutions for Your Specific Medical Mattress Needs

Recognizing that every healthcare setting and every patient presents unique requirements, Xinmattress excels in providing bespoke custom waterproof mattress solutions. Our deep expertise and flexible manufacturing capabilities allow us to tailor product specifications precisely, ensuring optimal alignment with your operational needs, clinical protocols, and patient demographics.

Our comprehensive customization options include:

- Dimensions and Shapes: We can produce mattresses in custom lengths, widths, and thicknesses to perfectly fit non-standard hospital beds, specialized bariatric frames, or unique stretchers. Furthermore, we can design mattresses with specific cut-outs or contours to accommodate medical equipment or enhance support in particular areas.

- Foam Density and Layering Configurations: Our engineers can adjust the Indentation Force Deflection (IFD) and density of individual foam layers, as well as the overall layering scheme. This allows for the creation of mattresses with specific pressure redistribution properties, tailored to address varying levels of pressure injury risk (e.g., low, moderate, high risk patients) or to accommodate different patient weight capacities. We can integrate high-resilience foam, memory foam, or gel-infused layers in precise combinations.

- Cover Materials and Features: We offer a diverse range of waterproof mattress fabrics, each with varying levels of breathability, stretch (bi-elastic for shear reduction), and integrated antimicrobial properties. Beyond functionality, we can also incorporate custom colors, specific branding elements, or unique zipper configurations to meet your aesthetic and operational preferences. Our materials are selected for their durability and resistance to common medical disinfectants.

- Zoning and Targeted Support: Our design capabilities include creating mattresses with specific zones of varying firmness or enhanced pressure relief. This allows for targeted support to highly vulnerable areas such as the heels, sacrum, and shoulders, significantly enhancing the efficacy of pressure injury prevention for specific patient conditions.

- Integrated Features and Accessories: We can incorporate a variety of integrated features to enhance functionality and patient safety. These include raised side bolsters for patient containment and fall prevention, robust transfer handles to assist caregivers, and unique corner designs to seamlessly fit articulating beds or specialized bed frames.

Our collaborative design process ensures that from the initial consultation and conceptualization to rigorous prototyping and final delivery, your custom waterproof mattress solution is precisely what your facility needs to enhance patient care, optimize resource utilization, and improve operational efficiency.

Application Cases & Success Stories

Xinmattress's Special Supply Medical Mattresses have been successfully deployed in diverse healthcare settings globally, consistently demonstrating tangible benefits and contributing to improved patient outcomes:

- Case Study 1: Large Urban Hospital (Pressure Injury Reduction & Cost Savings)

Challenge: A 500-bed urban hospital was grappling with a persistently high incidence of hospital-acquired pressure injuries (HAPIs) in their Intensive Care Unit (ICU) and general surgical wards. This issue not only impacted patient well-being but also led to substantial increases in healthcare costs due to prolonged patient stays and intensive wound care.

Solution: Xinmattress partnered with the hospital to implement a comprehensive upgrade. We supplied 300 units of our multi-layered, advanced pressure-redistributing medical mattress, specifically designed with enhanced shear reduction covers and optimal breathability. Additionally, we provided staff training on the proper usage of the new mattresses and best practices for patient positioning.

Outcome: Within just 12 months of deployment, the hospital reported a remarkable 35% reduction in Stage II and higher HAPIs across the targeted units. This significant improvement translated directly into substantial cost savings from reduced wound care treatments, shorter average patient stays, and a marked increase in overall patient satisfaction scores. The hospital management particularly praised the exceptional durability and the effortless cleaning and disinfection capabilities of the waterproof mattress covers, which streamlined their infection control protocols.

- Case Study 2: Regional Nursing Home (Enhanced Resident Comfort & Hygiene)

Challenge: A regional nursing home was experiencing challenges with resident comfort, frequently leading to agitation and difficulties with routine repositioning. Their existing mattresses were aged, difficult to clean thoroughly, and consequently posed ongoing infection control challenges, impacting both resident well-being and staff efficiency.

Solution: We conducted an on-site assessment and subsequently supplied 150 home medical mattress equivalents, meticulously tailored for the unique needs of long-term care residents. These mattresses featured enhanced comfort layers designed for extended use and were equipped with fully sealed, bleach-cleanable custom waterproof mattress covers, specifically chosen for their superior hygiene properties and resistance to cleaning agents.

Outcome: Following the upgrade, resident feedback indicated a dramatic and positive change in comfort levels and overall sleep quality, leading to reduced agitation and improved cooperation during care. Caregivers reported a significant improvement in the ease of cleaning and disinfection, which directly contributed to a noticeable reduction in facility-wide infection rates. The nursing home staff particularly appreciated the robust build quality and the extended lifespan of the new mattresses, which proved to be a sound long-term investment for the facility.

Trust and Transparency: Our Commitment to You

At Xinmattress, trustworthiness is the cornerstone of our operations and the foundation of our client relationships. We understand that investing in medical mattress solutions is a critical decision, directly impacting patient care quality, operational efficiency, and facility budgets. Here's how we build and maintain your trust through unwavering commitment to quality, clear communication, and robust support:

Quality Assurance & Certifications:

Our dedication to producing a medical grade mattress of the highest standard is validated by rigorous third-party certifications:

- ISO 9001:2015 Certified: This global standard demonstrates our commitment to a robust and continuously improving quality management system across all aspects of our operations, from design and development to production and service.

- ISO 13485:2016 Certified: Specifically tailored for Medical Devices, this certification ensures that our products meet stringent regulatory requirements for design, manufacturing, and distribution, affirming our compliance with the highest medical industry standards.

- FDA Registration/Compliance: Where applicable, our products comply with the U.S. Food and Drug Administration's medical device regulations, ensuring safety, effectiveness, and appropriate labeling for markets within the United States.

- CE Marking: For products sold within the European Union, our CE Mark indicates conformity with essential health, safety, and environmental protection standards, allowing for free movement within the EEA.

- Comprehensive Testing: Beyond certifications, every batch undergoes internal testing for parameters like pressure redistribution, fire retardancy, and fluid resistance, ensuring consistent performance and reliability.

Delivery and Support:

We believe in transparent and efficient processes to support your procurement needs:

Delivery Cycle: Our standard delivery time for existing stock items is typically 7-14 business days, depending on your location and order volume. For custom waterproof mattress orders, the lead time is usually 3-5 weeks from order confirmation, allowing for design, production, and quality control. We maintain proactive communication throughout the order process, providing regular updates on production status and shipping details.

Quality Warranty: All Xinmattress medical mattress products come with a comprehensive warranty to protect your investment. Typically, this includes a 5-7 year warranty for the foam core against manufacturing defects and structural integrity issues, and a 1-3 year warranty for the cover material against manufacturing faults, cracking, or delamination under normal usage conditions. Detailed warranty terms and conditions are provided with each purchase and are readily available upon request.

Customer Support: Our dedicated and knowledgeable customer support team is readily available to assist you. You can reach us via phone, email, or live chat during business hours. We provide prompt assistance with product inquiries, order tracking, technical support, troubleshooting, and after-sales service. We are committed to fostering long-term partnerships with our clients, offering ongoing support and expert advice to ensure you maximize the benefits of our best medical mattress solutions.

Frequently Asked Questions (FAQ) about Medical Mattresses

Q1: What is the primary difference between a standard mattress and a medical mattress?

A standard mattress is designed primarily for comfort in general residential use. In contrast, a medical mattress is specifically engineered to meet therapeutic, clinical, and infection control needs in healthcare settings. Key differences include superior pressure redistribution properties to prevent bedsores (pressure injuries), enhanced infection control features (such as fully sealed, waterproof mattress covers), greater durability to withstand demanding medical environments, and strict compliance with medical device standards (e.g., ISO 13485, fire retardancy standards like CAL 117), all crucial for effective medical care.

Q2: How do medical mattress designs specifically prevent pressure injuries?

Medical mattress designs prevent pressure injuries (also known as pressure ulcers or bedsores) primarily through advanced pressure redistribution. This is achieved by employing multi-layered foam constructions with varying densities and viscoelastic properties (like memory foam), and specialized zoning that precisely conforms to the body's contours. This technology effectively spreads the patient's body weight more evenly across the surface, significantly reducing concentrated pressure on vulnerable bony prominences. Additionally, low-friction, vapor-permeable covers minimize shear forces and manage skin moisture, both critical factors in preventing skin breakdown and promoting healthy skin.

Q3: What makes a waterproof mattress vitally important in a medical setting?

A waterproof mattress is absolutely crucial for maintaining stringent infection control and hygiene in any healthcare environment. It creates an impenetrable barrier, preventing bodily fluids (such as blood, urine, or vomit), medications, and other contaminants from seeping into the mattress core. This prevents the growth of bacteria, viruses, and molds, which can otherwise harbor odors and contribute to healthcare-associated infections. The fluid-proof surface also makes cleaning and disinfection much easier, faster, and more effective, significantly reducing the risk of cross-contamination between patients. Our famous waterproof mattress covers are also designed to be highly durable and resistant to common hospital-grade disinfectants for repeated cleaning cycles.

Q4: Can medical mattresses be effectively used at home for patient care?

Yes, absolutely. With the increasing emphasis on home medical mattress use, many patients recovering from surgery, managing chronic conditions, or requiring long-term care outside of a hospital setting can benefit significantly from the therapeutic features of a medical mattress. They provide the same critical benefits of pressure injury prevention, enhanced comfort, and easy hygiene in a familiar home environment, thereby enhancing the quality and continuity of medical care and supporting patient recovery and independence in their own space.

Q5: What is the typical lifespan and durability one can expect from a medical grade mattress?

The lifespan of a high-quality medical grade mattress can vary based on usage intensity, material quality, and adherence to proper maintenance protocols. Generally, premium pressure redistribution mattresses from reputable manufacturers like Xinmattress are engineered for superior durability and are designed to last 5-7 years for the foam core under normal medical usage conditions. The cover typically has a lifespan of 1-3 years, as it's subject to more direct wear and tear and cleaning. Regular inspection, adherence to cleaning guidelines, and prompt addressing of any issues can significantly help maximize their longevity and maintain optimal therapeutic performance.

Q6: Are medical mattresses universally fire retardant?

Yes, fire retardancy is a paramount safety requirement in all healthcare environments. Reputable medical mattress manufacturers ensure their products are meticulously designed and tested to meet or exceed strict national and international fire safety standards. These often include certifications such as California Technical Bulletin 117 (CAL 117), 16 CFR 1633 (a U.S. federal standard for mattress flammability), and British Standard BS 7177 for contract bedding. These stringent certifications guarantee that the mattress materials resist ignition and significantly limit flame spread, thereby enhancing the safety of both patients and the facility itself.

Q7: How do I choose the best medical mattress for my specific clinical or facility needs?

Choosing the best medical mattress requires a careful evaluation of several critical factors: the patient's individual risk for pressure injuries (ranging from low to very high), their mobility level, the required weight capacity (standard versus bariatric mattresses), the specific type of hospital bed frame it will be used with (e.g., articulating, static), and any unique clinical needs (e.g., exceptional fluid resistance, advanced breathability, or specific therapeutic zones). It is highly recommended to consult with a healthcare professional (e.g., a wound care nurse) or a specialized medical mattress supplier like Xinmattress, who can offer tailored custom waterproof mattress solutions, to ensure the optimal selection that maximizes patient outcomes and operational efficiency.

"The relentless pursuit of innovation in patient support surfaces is transforming healthcare. As institutions increasingly focus on preventive care, patient satisfaction, and operational efficiency, the role of a high-performance medical mattress becomes not just beneficial, but an indispensable component of modern medical care delivery."

- Excerpt from "Advances in Pressure Injury Prevention Technologies," presented at the International Wound Care Forum (IWCF)Further Reading and Resources

For more in-depth understanding of medical mattress technology, pressure injury prevention, and its profound impact on patient care and healthcare economics, we recommend exploring the following authoritative sources and academic publications:

- National Pressure Injury Advisory Panel (NPIAP) Clinical Practice Guidelines: The NPIAP provides evidence-based guidelines for the prevention and treatment of pressure injuries. Their resources are fundamental for understanding the clinical efficacy of support surfaces. https://npiap.com/page/ClinicalPracticeGuidelines

- Journal of Wound, Ostomy and Continence Nursing (JWOCN): This peer-reviewed journal frequently features cutting-edge research, clinical studies, and best practices related to wound care, including detailed analyses of various support surface technologies and their outcomes. https://journals.lww.com/jwocnonline/pages/default.aspx

- Agency for Healthcare Research and Quality (AHRQ) - Patient Safety Resources: AHRQ offers extensive resources, data, and tools focused on patient safety, including comprehensive guidelines and data on preventing hospital-acquired conditions like pressure ulcers. https://www.ahrq.gov/patient-safety/settings/hospital/qps-pressure-ulcers/index.html

- ISO 13485:2016 Medical devices — Quality management systems — Requirements for regulatory purposes: While the standard itself is for purchase, the ISO website provides an overview of this critical quality management system standard for medical device manufacturers, underscoring the importance of regulatory compliance in the industry. https://www.iso.org/standard/59750.html

- Wound Management & Prevention (WMP) Journal: This publication offers practical, evidence-based information for clinicians on wound management, ostomy care, and continence, often including articles on advanced support surface technologies and their application. https://www.woundmanagement.com.au/journal/index.html

-

How Hospital Mattress Choices Directly Impact Patient Comfort and CareNewsAug.05,2025

-

Hospital Mattress Topper Compatibility IssuesNewsAug.05,2025

-

Choosing the Best Hospital Mattress for Home UseNewsAug.05,2025

-

Blue Hospital Mattress Material Safety StandardsNewsAug.05,2025

-

Best Firm Hospital Bed Mattress for Elderly: A Wholesaler’s Guide to Quality Care SolutionsNewsAug.05,2025

-

Adjustable Bed Compatibility with Hospital MattressesNewsAug.05,2025

-

Sleep Tracking Mattress GuideNewsJul.28,2025