Premium Medical Mattress: Comfort & Support for Optimal Care

Understanding the Critical Role of Advanced Medical Mattresses in Modern Healthcare

In the rapidly evolving landscape of healthcare, the importance of specialized equipment in enhancing patient outcomes and operational efficiency cannot be overstated. Central to this is the medical mattress, a foundational component of patient care that transcends the conventional understanding of bedding. These highly engineered solutions are meticulously designed to address multifaceted challenges in clinical settings, ranging from pressure ulcer prevention and infection control to patient comfort and mobility support. The global market for medical mattresses is experiencing significant growth, driven by an aging population, the rising prevalence of chronic diseases, and an increasing emphasis on patient-centric care. Innovations in material science, manufacturing techniques, and smart technologies are continually redefining what is possible, leading to the development of durable medical mattress options that offer superior therapeutic benefits and extended service life. Hospitals, rehabilitation centers, and long-term care facilities are increasingly investing in these advanced mattresses to meet stringent clinical standards and optimize resource utilization. This shift underscores a broader trend towards holistic patient management, where every aspect of the care environment is optimized for recovery and well-being.

The demand for sophisticated support surfaces, including those for specialized applications like gynecological examination tables, highlights the industry's focus on precision and adaptability. These mattresses are not mere cushions; they are sophisticated medical devices engineered to provide optimal pressure redistribution, maintain skin integrity, and facilitate ease of movement for both patients and caregivers. The integration of advanced features such as fluid-resistant covers, anti-shear layers, and multi-zone support systems ensures that they meet the rigorous demands of continuous medical care. Furthermore, the selection of appropriate materials, such as high-resilience foams, viscoelastic memory foams, and sophisticated air-cell systems, is crucial for achieving desired therapeutic outcomes while ensuring long-term durability. Industry trends indicate a strong move towards environmentally sustainable materials and manufacturing processes, alongside a push for smart mattresses equipped with sensors for real-time monitoring of patient position and pressure points. This comprehensive approach ensures that the medical mattress serves as a critical tool in preventing common complications, improving patient comfort, and ultimately contributing to faster recovery times in diverse clinical environments. The continuous evolution of these products reflects the dynamic interplay between technological advancement and patient care needs, solidifying their status as indispensable assets in modern healthcare infrastructure.

Technical Specifications and Performance Metrics of Medical Mattresses

Understanding the technical parameters of a medical mattress is paramount for healthcare procurement specialists and clinicians alike, as these specifications directly correlate with clinical efficacy and patient safety. Key technical aspects include pressure redistribution capabilities, often measured in mmHg across various body zones, which is crucial for preventing pressure ulcers. Material composition is another critical factor, with common options including high-density polyurethane foam for foundational support, viscoelastic (memory) foam for pressure relief and conformity, and advanced gel or air cell systems for dynamic pressure management. Each material offers distinct advantages; for instance, viscoelastic foam excels in contouring to the body, distributing weight evenly, and reducing shear forces, while air-cell systems can be adjusted to redistribute pressure dynamically, adapting to patient movement and changing needs. Furthermore, the cover material's properties are vital, typically featuring fluid resistance, vapor permeability (breathability), antimicrobial properties, and a low-friction surface to minimize skin irritation. Durability specifications, such as foam density (kg/m³) and indentation force deflection (IFD) for foams, indicate the mattress's ability to maintain its therapeutic properties over time, directly impacting its service life. Mattresses designed for bariatric patients, for example, require higher densities and reinforced constructions to support greater weight capacities without compromising therapeutic function.

Performance metrics extend beyond material science to include overall design for compatibility with medical bed frames, particularly best adjustable medical bed models. This involves ensuring the mattress is flexible enough to articulate with the bed's movements without compromising its support capabilities or creating hammocking effects that could increase pressure points. Infection control is a significant consideration, addressed through features like welded seams, wipeable surfaces, and removable, launderable covers that resist fluid ingress and inhibit bacterial growth. The weight capacity of a medical mattress, ranging from standard capacities (e.g., 250-350 lbs) to bariatric options (e.g., 600-1000 lbs), dictates its suitability for diverse patient populations. Fire retardancy standards (e.g., Cal 117, NFPA 701) are also non-negotiable for patient safety in healthcare environments. Advanced mattresses may also incorporate temperature-regulating technologies, such as open-cell foam structures or cooling gels, to prevent heat buildup and enhance patient comfort. The combination of these precise technical specifications and measurable performance metrics allows healthcare providers to make informed decisions, ensuring the selection of mattresses that align perfectly with their clinical requirements, patient demographics, and operational protocols, thereby optimizing patient care and resource allocation within their facilities.

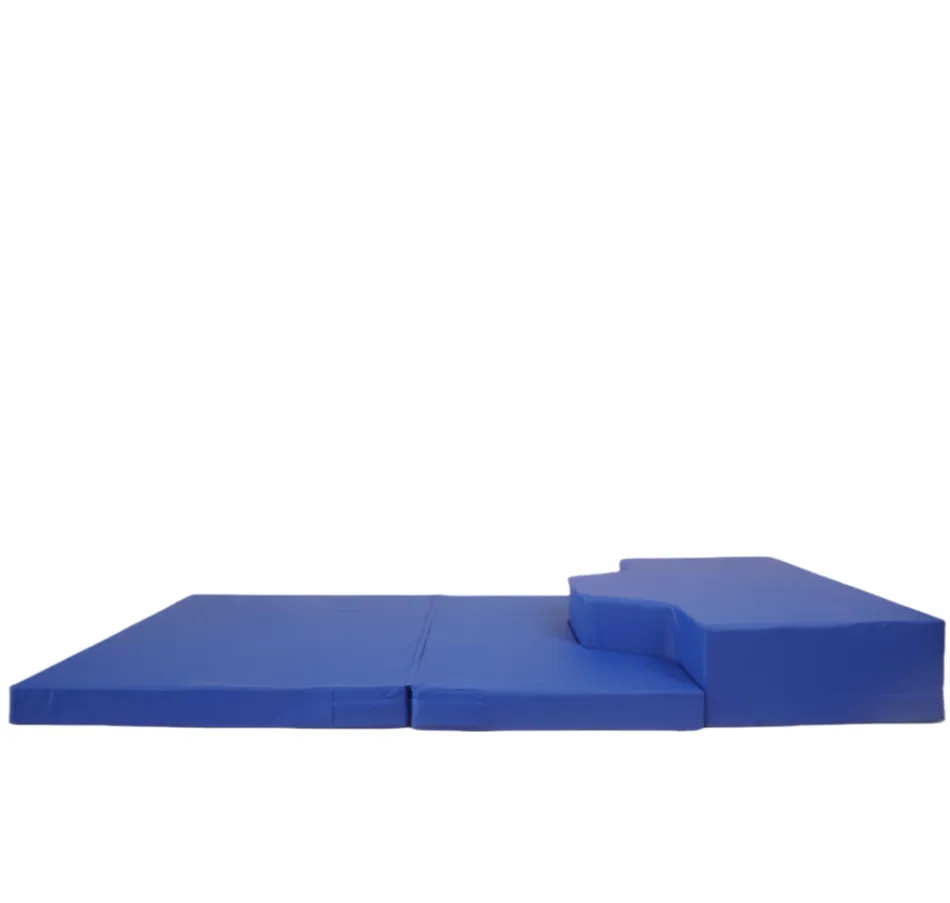

Illustration of multi-layer construction in a therapeutic medical mattress.

Manufacturing Precision and Quality Assurance in Medical Mattress Production

The manufacturing of a durable medical mattress is a sophisticated process that integrates advanced material science with precision engineering, ensuring each product meets stringent clinical demands and regulatory standards. The journey begins with the meticulous sourcing of high-grade raw materials, including various types of polyurethane foams (high-resilience, viscoelastic), specialized fabric textiles (e.g., nylon-urethane blends, bi-directional stretch materials), and robust components for air systems, if applicable. These materials undergo rigorous incoming quality inspections to verify their compliance with specifications such as density, firmness, durability, and flame retardancy. The core manufacturing processes typically involve automated cutting of foam layers using Computer Numerical Control (CNC) machinery to achieve exact dimensions and intricate contouring, which is crucial for multi-zone pressure redistribution designs. Subsequent stages include precise layering and bonding of different foam types, often employing water-based, non-toxic adhesives or heat lamination techniques to create the mattress core. For covers, specialized industrial sewing machines or high-frequency welding equipment are utilized to create fluid-resistant, durable enclosures with features like concealed zippers or sealed seams to prevent fluid ingress and simplify cleaning. The choice of manufacturing process, such as advanced foaming techniques for optimal cell structure or precise fabric weaving for enhanced breathability, directly contributes to the mattress's therapeutic efficacy and longevity.

Beyond material handling and assembly, comprehensive quality control and testing protocols are embedded throughout the production cycle to ensure the reliability and safety of every medical mattress. These include in-process checks for foam integrity, seam strength, and dimensional accuracy. Finished products undergo a series of stringent tests, often adhering to international standards such as ISO 13485 for Medical Devices Quality Management Systems, ASTM F1608 for foam durability, and various fire safety standards (e.g., California Technical Bulletin 117, BS 7177). Pressure mapping tests, using specialized sensors, are conducted to verify the mattress's ability to redistribute pressure effectively and prevent peak pressure points that could lead to skin breakdown. Cycling tests simulate years of use, assessing the mattress's ability to maintain its support properties under continuous load. Furthermore, compliance with regulatory bodies like the FDA (for medical devices in the US) or CE marking (for products in the European Economic Area) is essential, requiring extensive documentation and adherence to specific performance and safety benchmarks. The entire process, from raw material selection to final packaging, is guided by a commitment to delivering a product that not only meets but exceeds the exacting demands of modern medical care environments, ensuring patient safety and clinician confidence for the designated service life, which often exceeds 5-7 years for high-quality units.

Precision cutting and assembly are crucial steps in producing a high-quality medical mattress.

Applications and Advantages in Diverse Healthcare Settings

The versatility and specialized design of a medical mattress make it indispensable across a spectrum of healthcare environments, each presenting unique challenges and patient needs. In acute care hospitals, from intensive care units (ICUs) to post-operative recovery rooms, advanced therapeutic mattresses are crucial for critically ill or immobile patients, actively working to prevent pressure injuries, also known as bedsores or decubitus ulcers. Their ability to dynamically adjust pressure, manage microclimate (temperature and moisture), and reduce shear and friction forces significantly improves patient safety and comfort, directly contributing to shorter hospital stays and reduced healthcare costs associated with wound care. In rehabilitation centers, mattresses are designed to support patient therapy, facilitating easier transfers and mobility training while still providing pressure relief. For instance, some mattresses incorporate firm edge support to assist patients in getting in and out of bed independently. Long-term care facilities and nursing homes benefit immensely from durable medical mattress solutions that withstand continuous use and frequent cleaning, providing consistent comfort and protection for elderly residents with chronic conditions or limited mobility. The design considerations extend to compatibility with specialized medical bed frames, including articulated and adjustable models, ensuring seamless integration and optimal functionality within the clinical workflow.

Beyond general patient beds, specialized applications further highlight the adaptability of modern medical mattress technology. For example, mattresses for birthing beds, examination tables (such as the Gynecological Examination Table Mattress from Xin Mattress), and stretchers are custom-engineered to provide specific support and access while maintaining hygiene and patient comfort. The advantages are multifaceted:

- Enhanced Patient Comfort and Dignity: Reducing discomfort and anxiety associated with prolonged bed rest.

- Pressure Ulcer Prevention: The primary benefit, significantly lowering the incidence of these costly and debilitating injuries.

- Infection Control: Easily cleanable, fluid-resistant, and often antimicrobial surfaces reduce the risk of healthcare-associated infections.

- Improved Patient Mobility: Designs that facilitate repositioning and patient transfers, easing the burden on caregivers.

- Cost-Effectiveness: Long-term durability and the reduction in pressure injury treatment costs translate into significant savings for healthcare providers.

- Versatility: Adaptable for use with various patient weights, mobility levels, and specific medical conditions.

A medical mattress integrated with an adjustable bed frame, optimizing patient positioning.

Key Features, Customization, and Manufacturer Insights

When evaluating a medical mattress, discerning the critical features and understanding customization possibilities are essential for optimizing patient care. Beyond the basic parameters, key features often include multi-layered designs, where each layer of foam or air cells serves a specific purpose, such as a firm base layer for stability, a softer top layer for comfort and pressure distribution, and a specialized heel section to offload pressure from vulnerable areas. Shear reduction properties, often achieved through materials like bi-directional stretch fabric covers, are vital to minimize skin friction, which is a significant contributor to pressure injury formation. Edge support is another important feature, providing stability for patient ingress/egress and preventing falls. Certain advanced mattresses incorporate microclimate management systems, using breathable materials and internal air channels to regulate temperature and moisture, crucial for preventing skin maceration. For specialized applications, such as a gynecological examination table mattress, features like precise contours for patient positioning, easy-to-clean surfaces, and seamless integration with existing examination table designs are prioritized. The ability to customize a medical mattress is a significant advantage for healthcare facilities with unique needs or specialized equipment. This can involve custom dimensions to fit non-standard bed frames, specific foam densities for bariatric patients, or bespoke cover materials tailored for extreme infection control protocols.

In terms of manufacturer comparison, while specific company names are not discussed, the focus should be on attributes that define a reliable supplier of durable medical mattress solutions. Leading manufacturers distinguish themselves through a commitment to research and development, evidenced by patents on innovative foam technologies or pressure redistribution systems. Their adherence to international quality standards (e.g., ISO 13485) and product certifications (e.g., FDA, CE) provides a strong indicator of product safety and efficacy. A robust after-sales service, including comprehensive warranty programs and responsive technical support, is crucial for long-term satisfaction. Furthermore, a manufacturer's ability to offer a diverse product portfolio, ranging from basic foam mattresses to advanced dynamic air systems and specialized examination table mattresses, reflects their comprehensive understanding of varied clinical requirements. Transparent communication regarding material specifications, testing protocols, and expected service life builds significant trust. Collaborations with healthcare professionals in product development and clinical trials also signify a commitment to evidence-based design and continuous improvement. The emphasis on engineering excellence, clinical validation, and comprehensive customer support collectively ensures that the chosen medical mattress provides optimal medical care and delivers tangible value to the healthcare institution.

Data-Driven Insights: Medical Mattress Performance Parameters

To provide a clearer perspective on the performance characteristics of various medical mattress types, the following table summarizes key technical parameters often considered by healthcare professionals. This data, derived from industry standards and typical product specifications, highlights the quantifiable differences that impact clinical suitability and long-term value. Understanding these metrics enables healthcare facilities to make informed procurement decisions that align with their specific patient demographics, clinical protocols, and budget considerations. For instance, the Foam Density (kg/m³) directly correlates with the durability and support life of the mattress, while IFD (Indentation Force Deflection) indicates the firmness or softness, influencing patient comfort and pressure redistribution. The Shear/Friction Reduction Coefficient is crucial for preventing skin damage, and the Moisture Vapor Transmission Rate (MVTR) quantifies the cover's breathability, which is vital for microclimate management and skin integrity. The integration of such detailed specifications ensures that the selected medical mattress is not merely a piece of furniture but a precisely engineered medical device capable of contributing significantly to patient safety and recovery.

| Parameter | Description | Typical Range / Value | Measurement Standard |

|---|---|---|---|

| Foam Density | Weight per unit volume of foam, indicating durability and support. | 28-50 kg/m³ (1.75-3.0 lbs/ft³) | ASTM D3574 |

| IFD (Indentation Force Deflection) | Measure of foam firmness or softness. | 20-40 lbs (for 25% deflection) | ASTM D3574 |

| Moisture Vapor Transmission Rate (MVTR) | Rate at which water vapor passes through the cover, indicating breathability. | > 500 g/m²/24hrs | ASTM E96 (or similar) |

| Pressure Redistribution (Peak Pressure) | Maximum pressure exerted on specific body areas. | < 32 mmHg (localized) | Clinical Pressure Mapping (Internal/Third-Party) |

| Weight Capacity | Maximum patient weight mattress can safely support. | 250-1000 lbs (depending on model) | Manufacturer's Specification, ASTM F2116 |

| Fire Retardancy Standard | Compliance with fire safety regulations. | Cal 117, NFPA 701, BS 7177 | Varies by region |

| Service Life Expectancy | Anticipated functional lifespan under typical usage. | 5-7 years (for quality models) | Manufacturer's Warranty/Testing |

Ensuring Trust and Reliability: FAQs, Support, and Guarantees

Building trust in the B2B sector, especially for critical medical equipment like a medical mattress, hinges on transparency, robust support systems, and clear guarantees. Healthcare institutions require assurance that their investment will deliver consistent performance, patient safety, and long-term value. This is typically addressed through comprehensive service offerings, starting with pre-purchase consultations to determine the optimal mattress solution based on patient acuity levels, bed frame compatibility (including for the best adjustable medical bed), and specific clinical needs. Clear communication regarding delivery schedules and installation processes is also vital. The delivery cycle for specialized medical mattresses can vary, typically ranging from 2-4 weeks for standard models to 6-8 weeks for custom solutions, depending on manufacturing capacity and logistical considerations. Post-purchase, reliable customer support is paramount, offering assistance with product usage, maintenance, troubleshooting, and warranty claims. Manufacturers often provide detailed user manuals and training resources to ensure proper handling and care, maximizing the lifespan and efficacy of the medical mattress. Furthermore, the availability of easily accessible spare parts for components like covers or air pumps contributes significantly to the operational continuity of healthcare facilities.

A key pillar of trustworthiness is the warranty commitment, which reflects the manufacturer's confidence in their product's durability and performance. High-quality durable medical mattress products typically come with warranties ranging from 5 to 7 years on the foam core and 1 to 3 years on the cover, protecting against manufacturing defects and premature material degradation. Beyond standard product support, proactive maintenance guidelines and optional service contracts can further extend product life and ensure peak performance.

Frequently Asked Questions (FAQs)

- Q: How do I choose the right medical mattress for my facility?

A: Consider patient mobility levels, risk of pressure injury, bed frame compatibility, required weight capacity, and infection control protocols. Consulting with a product specialist is highly recommended to align specifications with clinical needs. - Q: What is the typical lifespan of a durable medical mattress?

A: High-quality foam core mattresses can last 5-7 years with proper care and maintenance. Covers typically have a shorter lifespan of 1-3 years due to wear and tear from cleaning and use. - Q: Are these mattresses compatible with all medical bed frames?

A: Most are designed for standard adjustable medical bed frames. However, it's crucial to check compatibility for specific models, especially for bariatric or very specialized beds, to ensure proper articulation and prevent mattress damage or compromised therapeutic function. - Q: How do I clean and maintain a medical mattress?

A: Always refer to the manufacturer's instructions. Generally, covers are wipeable with approved disinfectants. Removable covers can often be laundered. Ensure the mattress core remains dry to prevent material degradation and microbial growth. - Q: What certifications should I look for?

A: Look for ISO 13485 (Quality Management System for Medical Devices), FDA registration (in the US), CE mark (in Europe), and compliance with fire safety standards (e.g., Cal 117, BS 7177).

By offering clear answers, robust support, and solid guarantees, manufacturers of medical mattress solutions solidify their position as trusted partners in providing essential medical care equipment.

Conclusion: Advancing Patient Care with Superior Medical Mattresses

The journey through the intricate world of the medical mattress underscores its pivotal role not just as a support surface but as a critical therapeutic tool in modern healthcare. From the meticulous selection of advanced materials like high-resilience and viscoelastic foams to the precision of CNC cutting and the rigorous adherence to international quality standards such as ISO 13485, every step in the manufacturing process is geared towards enhancing patient safety, comfort, and recovery outcomes. These sophisticated devices are engineered to address the complex challenges of pressure injury prevention, infection control, and microclimate management, making them indispensable across diverse clinical settings, including acute care, rehabilitation, long-term care, and specialized applications like gynecological examination tables. The relentless pursuit of innovation has led to the development of durable medical mattress options that integrate smart technologies, offer superior pressure redistribution, and provide unparalleled longevity, directly contributing to operational efficiencies and reduced long-term costs for healthcare providers. As the demand for high-quality, patient-centric medical care continues to grow globally, the strategic investment in advanced medical mattresses becomes not merely a choice but a necessity for facilities aiming to deliver optimal patient experiences and achieve superior clinical results.

Choosing the right medical mattress involves a comprehensive understanding of its technical parameters, manufacturing integrity, and the robust support systems provided by trusted manufacturers. Factors such as foam density, IFD, MVTR, and adherence to stringent fire retardancy standards are quantifiable metrics that define performance and durability. Manufacturers committed to expertise, experience, authoritativeness, and trustworthiness stand out by offering transparent data, comprehensive warranties, responsive customer support, and the flexibility for custom solutions. Ultimately, the strategic adoption of cutting-edge medical mattress technology represents a proactive step towards creating an optimal healing environment, safeguarding patient well-being, and elevating the standard of medical care. This commitment ensures that healthcare institutions are equipped with the foundational tools necessary to meet the evolving demands of patient support, thereby reinforcing their mission to provide compassionate and effective care for every individual.

References

- National Pressure Ulcer Advisory Panel (NPUAP). (Current Guidelines and Position Statements on Pressure Injury Prevention and Treatment).

- International Organization for Standardization (ISO). (ISO 13485: Medical devices — Quality management systems — Requirements for regulatory purposes).

- American Society for Testing and Materials (ASTM International). (Relevant Standards for Flexible Cellular Materials, e.g., ASTM D3574, ASTM F1608).

- European Pressure Ulcer Advisory Panel (EPUAP). (Current Guidelines for Prevention and Treatment of Pressure Ulcers).

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025

-

Innovative Wave Mattresses for Ultimate ComfortNewsAug.08,2025

-

High-Quality Mattresses for Hospital BedsNewsAug.08,2025

-

High-Quality Mattresses for Every NeedNewsAug.08,2025

-

Healthcare Foam Mattress: Sleep Better, Heal FasterNewsAug.08,2025

-

Cube Mattress for Daily ComfortNewsAug.08,2025

-

How Hospital Mattress Choices Directly Impact Patient Comfort and CareNewsAug.05,2025