medical bed positions factories

Understanding Medical Bed Positions The Role of Factories in Healthcare

Medical beds are essential equipment in healthcare settings, providing patients with comfort and support during their recovery. The positioning of these beds is critical, as it can significantly impact patient health outcomes. Factories that specialize in manufacturing medical beds play a crucial role in ensuring that these crucial components of healthcare facilities are not only durable but also versatile and adaptable to various medical needs.

The Importance of Medical Bed Positions

Medical beds are designed with multiple positions to accommodate a variety of patient needs. Common positions include flat, semi-fowler, fowler, trendelenburg, and reverse trendelenburg. Each position serves a unique purpose; for instance, the fowler position elevates the upper body, which can help improve breathing and reduce the risk of aspiration in patients with respiratory issues. Conversely, the trendelenburg position is often used in emergencies to enhance venous return and increase blood flow to vital organs.

The ability to adjust bed positions also aids nursing staff in providing care. By repositioning beds, caregivers can minimize strain while performing patient care tasks, reducing the risk of injury to both patients and healthcare workers. Therefore, the design and functionality of medical beds have a direct impact on the efficiency of healthcare services and patient safety.

Role of Factories in Medical Bed Production

Factories that specialize in producing medical beds must adhere to stringent quality standards and regulations to ensure that their products meet healthcare needs. The process begins with research and development, where manufacturers analyze trends in patient care and feedback from healthcare professionals. This data informs the design of medical beds, ensuring they feature the latest technology and ergonomic designs.

medical bed positions factories

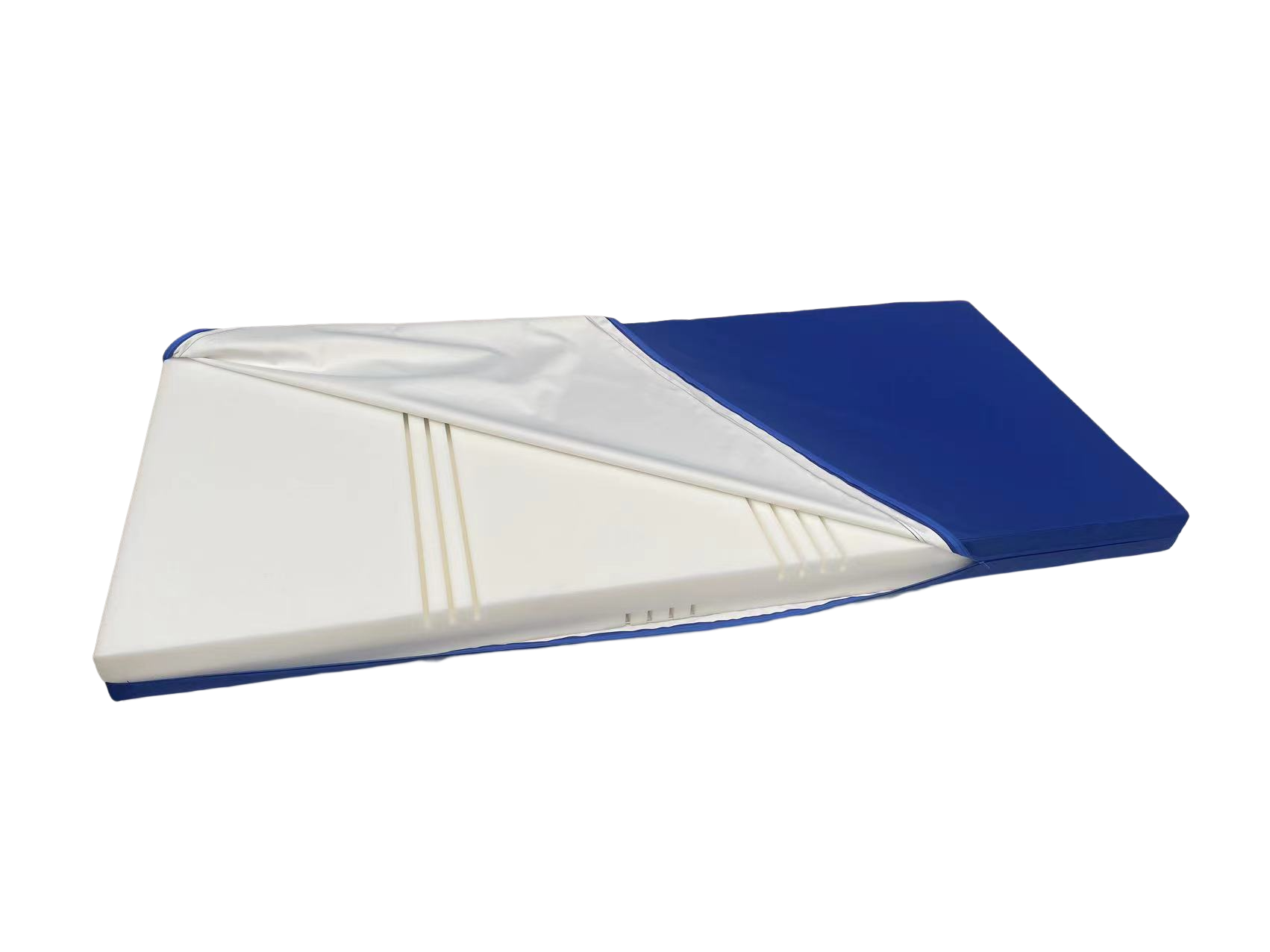

In terms of manufacturing, these factories utilize advanced machinery and materials to create beds that are not only robust but also easy to sanitize. Given the rising concerns about infection control in healthcare facilities, it's essential for medical beds to be made of materials that can withstand rigorous cleaning processes without degrading in quality.

Furthermore, factories must also consider the aesthetic aspects of medical beds. As healthcare environments evolve, the focus has shifted towards creating a more welcoming and less clinical atmosphere for patients. Manufacturers have started incorporating features like softer colors, more appealing designs, and patient-friendly controls, which can contribute to reducing the anxiety levels of patients.

Innovations in Medical Bed Technology

Recently, medical bed factories have begun to integrate smart technology into their designs. Features such as automated positioning, weight-sensing capabilities, and monitoring systems that track patient vitals are gaining popularity. These innovations not only enhance patient care but also provide valuable data that healthcare providers can use to make informed decisions regarding treatment and adjustments to patient care plans.

Another emerging trend is the emphasis on sustainability in manufacturing processes. Factories are increasingly adopting eco-friendly practices, using recyclable materials, and optimizing energy use during production. This is not only beneficial for the environment but also appeals to healthcare facilities seeking to enhance their sustainability credentials.

Conclusion

In summary, the positioning of medical beds is a pivotal aspect of patient care, influencing not only comfort but also clinical outcomes. Factories dedicated to the production of medical beds are fundamental to the healthcare system, as they provide the necessary equipment that supports patient recovery and safety. With ongoing innovations and a commitment to quality, these factories continue to evolve in response to the changing needs of healthcare, ultimately benefiting both patients and healthcare providers alike.

-

The Science Behind Silicon Mattresses for Critical Care EnvironmentsNewsJul.16,2025

-

The Role of Wave Mattress Systems in Pressure Ulcer PreventionNewsJul.16,2025

-

The Role of ICU Nursing Silicon Mattress in Preventing Pressure UlcersNewsJul.16,2025

-

Long-Term Bedridden Patients and the Advantages of Silicon Mattresses in the ICUNewsJul.16,2025

-

From ICU to Home Care: Expanding the Use of Silicon Mattresses for Nursing NeedsNewsJul.16,2025

-

Choosing the Right Wave Mattress for Different Levels of Patient CareNewsJul.16,2025

-

The Effect of Coconut Foam Mattress Breathability and Humidity Regulation on Improving Sleep QualityNewsJul.03,2025