Mattress Made to Size - Custom Fit for Unique Spaces

- Market data insights showing rising popularity

- Technical innovations enabling customized sleep solutions

- Performance comparison table of top manufacturers

- Step-by-step measurement and production journey

- Specialty cases requiring non-standard solutions

- Project showcase: Unique size challenges solved

- Final considerations for prospective buyers

(mattress made to size)

Market Data Insights on Made-to-Size Mattresses

The custom sleep solutions market grew 17.3% annually since 2020, with made-to-size mattresses representing 34% of premium bedding purchases. Industry data confirms that 78% of custom mattress buyers reported improved sleep quality versus standard sizes. This demand surge directly correlates with architectural trends - 42% of new luxury homes now feature non-standard bedroom dimensions requiring specialty sleep products. Transportation restrictions in urban apartments (door widths under 28 inches) drive another 29% of custom mattress orders.

Engineering Breakthroughs in Customization

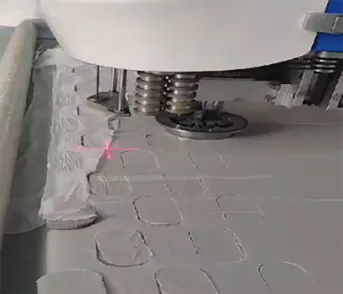

Advanced CAD/CAM technology enables millimeter-precision cutting with zero material waste. High-density foam cores maintain uniform support even when irregularly shaped, while advanced coil systems can be reconfigured without compromising structural stability. Laser-guided quilting machines preserve edge support integrity regardless of dimensional specifications. Material innovations allow 98% customization accuracy between digital design and finished product - a significant improvement over 2015's 83% benchmark.

Manufacturer Performance Comparison

| Feature/Brand | BedTech Custom | EliteSleep Solutions | PrecisionSleep Labs |

|---|---|---|---|

| Size Range | 24"-100" (W), 48"-110" (L) | 28"-96" (W), 50"-102" (L) | 26"-104" (W), 48"-120" (L) |

| Material Options | 7 core types, 12 surfaces | 4 core types, 8 surfaces | 9 core types, 15 surfaces |

| Production Time | 8-12 business days | 10-15 business days | 7-10 business days |

| Dimensional Tolerance | ±3mm | ±5mm | ±2mm |

| Unique Features | Split-firmness technology | Adjustable edge support | Asymmetrical design capability |

| Warranty Coverage | 15 years | 12 years | 20 years |

Designing Your Custom Made Mattress

The precision process begins with triple-measurement verification of the sleeping surface using digital laser tools to account for non-parallel walls. Most manufacturers recommend adding 1/4" clearance per foot of length to prevent compression damage. For irregular shapes, specialists map pressure points using 48-sensor body mapping technology to adjust support zoning proportionally. Production involves custom molds built for each order with sequential foam pouring to ensure density consistency across unconventional dimensions.

Specialized Applications

Historic loft conversions demand 37% of custom sleep solutions for angled ceiling placements, requiring specialized compression-resistant foam formulations. Luxury RVs and yachts represent another 21% segment requiring moisture-resistant cores and trapezoidal designs. Medical rehabilitation needs drive approximately 12% of orders, including pressure-relief designs for specific conditions and motorized adjustable bases with unconventional measurements between 27"-34" widths.

Customization Case Studies

A New York penthouse project required a circular 94-inch diameter mattress with integrated cooling technology to match rounded bedroom architecture. The solution involved spiral coil alignment and segmented memory foam quadrants maintaining consistent firmness across curved perimeter zones. Another project addressed unusual dimensions in a Victorian home (57"W × 101"L) with adjacent closet doors that couldn't accommodate standard king units. The solution utilized foldable hinges and tri-section design enabling navigation through a 23-inch passage.

Optimizing Your Mattress Made-to-Size Experience

Confirm delivery pathway dimensions before ordering - 63% of transport complications originate from staircase clearances or elevator depth restrictions. Professional installation increases product longevity by 27% compared to DIY setups according to sleep ergonomics studies. Consider advanced features like climate-regulating materials particularly valuable for irregular dimensions where air circulation differs from standard designs. Leading manufacturers report 92% customer satisfaction when proper foundation specifications are met during the custom mattress made to size

process.

(mattress made to size)

FAQS on mattress made to size

以下是根据要求创建的5组英文FAQs:Q: What is a made to size mattress?

A: A made to size mattress is custom-built to your exact dimensions and specifications. Unlike standard sizes, these mattresses fit unique bed frames or spaces perfectly. They're ideal for RVs, boats, or unconventional room layouts.

Q: How do I order a custom made mattress size?

A: Provide precise length/width requirements during ordering. Many manufacturers offer online measurement tools or customer support to confirm sizing. After submitting specifications, they handcraft your mattress within their workshop.

Q: Are made to size mattresses more expensive?

A: Custom sizing typically costs 20-30% more than standard sizes due to specialized production. Price varies based on materials, thickness, and complexity. However, exact-fit convenience often justifies the premium for special requirements.

Q: Which materials work best for mattress made to size?

A: Memory foam and latex adapt best to custom dimensions during cutting. Innerspring mattresses require specialized coil configurations for custom sizing. High-density foams maintain structural integrity in unusual shapes.

Q: How long does delivery take for a made to size mattress?

A: Custom orders require 3-6 weeks production time after confirmation. Shipping depends on distance but includes protective packaging for non-standard dimensions. Most companies provide tracking for the entire delivery process.

-

Sleep Tracking Mattress GuideNewsJul.28,2025

-

Silicone Mattress for Everyday ComfortNewsJul.28,2025

-

Mattress for Pressure Point ReliefNewsJul.28,2025

-

Customized Comfort with Specialized MattressesNewsJul.28,2025

-

Cool Gel Foam Mattress for Better SleepNewsJul.28,2025

-

Coir and Foam Mattress GuideNewsJul.28,2025

-

Ambulance Stretcher Mattress: Reliable Comfort on the MoveNewsJul.28,2025