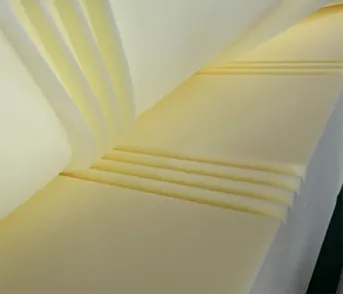

latex foam cut to size

Laser Foam Cutting Precision and Customization

In various industries, from packaging and construction to automotive and aerospace, the need for customized materials that fit specific dimensions and shapes is growing. Among the many options available for obtaining such bespoke products, laser foam cutting has emerged as a highly precise and efficient method. This technology allows for the creation of foam products cut to size, catering to the exact requirements of various applications.

Understanding Laser Foam Cutting

Laser foam cutting involves the use of a high-powered laser to slice through foam materials with extreme precision. The process begins with the preparation of a digital design, which can be created using CAD software. This design is then fed into a laser cutting machine, which interprets the data and executes the cut. The laser beam's intensity, speed, and angle can be adjusted, allowing for intricate designs, sharp edges, and minimal waste.

One of the most significant advantages of using laser cutting for foam is its capability to produce complex geometries that traditional methods may struggle to achieve. Whether dealing with polyethylene, polyurethane, polystyrene, or other foam types, manufacturers can create tailored parts that meet specific requirements, resulting in a highly efficient production process.

Advantages of Laser Foam Cutting

1. Precision and Accuracy At the heart of laser cutting is its precision. The laser can create cuts with tolerances as tight as 0.1 mm, ensuring that the final product meets exact specifications. This level of accuracy is crucial for applications in industries such as aerospace, where any deviation can lead to significant failures.

2. Speed Laser cutting is considerably faster than traditional cutting methods. Once the design is prepared, the actual cutting process can be completed in a fraction of the time it would take by hand or with other mechanisms. This efficiency enables quicker turnaround times for prototypes and mass production runs alike.

latex foam cut to size

3. Minimal Waste The precision of laser cutting means that very little material is wasted during the cutting process. This aspect not only reduces costs associated with raw materials but also contributes to environmentally sustainable practices by minimizing the environmental footprint of production.

4. Versatility Laser cutting technology can work with a variety of foam materials, such as EVA foam, memory foam, and closed-cell foams. Additionally, it can handle multiple thicknesses and densities, which makes it suitable for creating a wide range of products – from packaging solutions to insulation materials.

5. Customization In today’s market, where consumer preferences are increasingly personalized, the ability to easily customize products is a significant advantage. Laser foam cutting enables manufacturers to adapt their offerings quickly, responding to shifts in demand without the need for extensive changes to machinery or production processes.

Applications of Laser Foam Cutting

The applications of laser foam cutting are extensive. In the packaging industry, custom foam inserts can provide protection for fragile items during transit, ensuring that products arrive at their destination undamaged. In construction, foam can be cut to size for custom insulation solutions, enhancing energy efficiency. The automotive industry also benefits from this technology by creating lightweight foam components, which contribute to weight reduction and improved fuel efficiency.

Moreover, the healthcare sector utilizes laser-cut foam for medical cushioning and padding that requires specific shapes and sizes for comfort and support. The gaming and entertainment industries also exploit foam cutting for props and themed decorations, showcasing the versatility of this technology.

Conclusion

In conclusion, laser foam cutting is revolutionizing how industries approach the customization and production of foam products. Its precision, speed, and versatility offer significant advantages over traditional cutting methods, allowing businesses to meet the growing demand for bespoke solutions efficiently. As technology continues to evolve, it is expected that laser foam cutting will become an even more integral part of various manufacturing processes, driving innovation and excellence across diverse fields. Whether for packaging, insulation, or customized components, laser foam cutting stands out as a go-to method for those seeking high quality and tailored solutions in the world of foam fabrication.

-

The Science Behind Silicon Mattresses for Critical Care EnvironmentsNewsJul.16,2025

-

The Role of Wave Mattress Systems in Pressure Ulcer PreventionNewsJul.16,2025

-

The Role of ICU Nursing Silicon Mattress in Preventing Pressure UlcersNewsJul.16,2025

-

Long-Term Bedridden Patients and the Advantages of Silicon Mattresses in the ICUNewsJul.16,2025

-

From ICU to Home Care: Expanding the Use of Silicon Mattresses for Nursing NeedsNewsJul.16,2025

-

Choosing the Right Wave Mattress for Different Levels of Patient CareNewsJul.16,2025

-

The Effect of Coconut Foam Mattress Breathability and Humidity Regulation on Improving Sleep QualityNewsJul.03,2025