diamond memory foam mattress factories

Exploring the World of Diamond Memory Foam Mattress Factories

In recent years, the demand for high-quality mattresses has surged, as more people recognize the importance of good sleep for their overall health and well-being. Among the popular choices available in the market, diamond memory foam mattresses have emerged as a preferred option for many. These mattresses are known for their comfort, durability, and enhanced support, which is largely due to the innovative manufacturing techniques employed by leading factories specializing in these products.

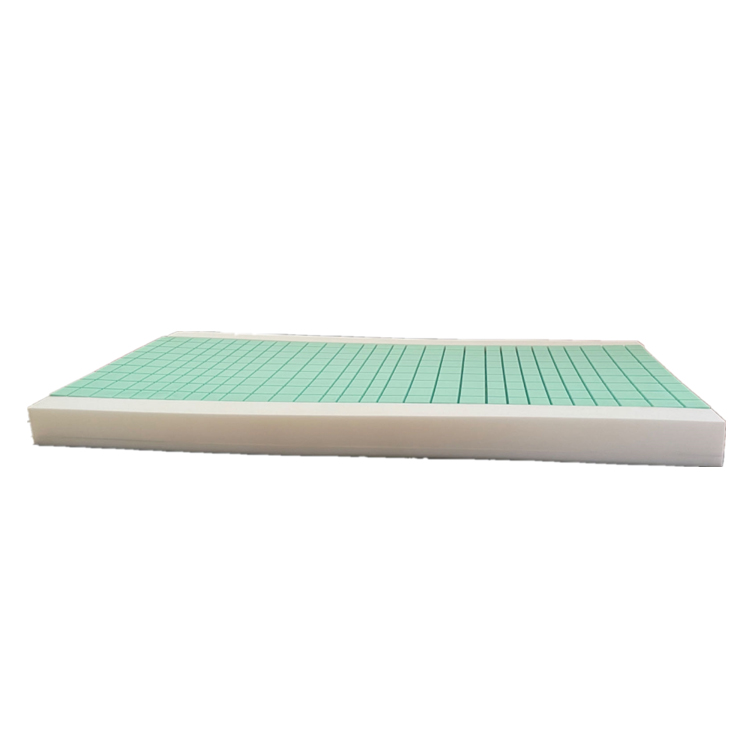

Diamond memory foam mattresses are distinguished by their unique formulation that typically combines multiple layers of foam, including a supportive base layer, a contouring memory foam layer, and a cooling gel layer. This combination provides an optimal sleeping experience by balancing support and comfort. As a result, consumers are increasingly turning to these products, prompting factories to ramp up production to meet the growing demand.

The Manufacturing Process

The manufacturing of diamond memory foam mattresses begins with the selection of high-quality materials. Factories source premium-grade polyurethane foam and durable fabrics that ensure longevity and performance. The foam is often treated with various additives to enhance its properties, such as thermal regulation, durability, and hypoallergenic features. Such careful selection of materials is crucial in creating a mattress that not only feels good but is also built to last.

Once the materials are procured, the production process kicks off. Most modern factories employ advanced technology and machinery for cutting, shaping, and assembling the foam layers. Large automated machines precisely cut the foam to the required dimensions, ensuring uniformity and quality across all products. After cutting, the foam layers are combined using strong adhesives that bond the materials together, making sure that each layer works harmoniously to provide the desired comfort and support.

Quality Control

diamond memory foam mattress factories

Quality control is a vital aspect of the manufacturing process at diamond memory foam mattress factories. Each mattress undergoes a series of rigorous tests to assess its durability, comfort levels, and conformity to safety standards. Factory technicians often conduct tests such as firmness testing and durability assessments to ensure that each mattress meets these high standards before it reaches the consumer. This commitment to quality not only enhances customer satisfaction but also builds brand reputation and loyalty in a competitive market.

Sustainability Practices

In today’s conscious consumer landscape, many mattress factories are also adopting sustainable manufacturing practices. This includes sourcing eco-friendly materials, minimizing waste during production, and using environmentally safe adhesives and chemicals. Some factories even implement recycling programs for old mattresses, thereby reducing their ecological footprint.

Moreover, many manufacturers are beginning to offer customizable diamond memory foam mattresses that cater to individual sleep preferences. By allowing consumers to choose aspects such as firmness levels and additional features like adjustable bases, factories are able to meet a wider range of customer needs, making their products even more appealing.

Conclusion

The evolution of diamond memory foam mattress factories is a testament to the ever-changing landscape of the sleep industry. With a focus on innovation, quality control, and sustainability, these factories are playing a critical role in enhancing the sleep experience for consumers worldwide. As advancements continue to emerge, it will be exciting to see how the mattress industry evolves further, ensuring that restful sleep remains attainable for everyone. In the end, the combination of quality craftsmanship and materials will keep diamond memory foam mattresses at the forefront of the industry, promising a good night’s sleep for years to come.

-

The Effect of Coconut Foam Mattress Breathability and Humidity Regulation on Improving Sleep QualityNewsJul.03,2025

-

How Wave Mattress Systems Improve Blood Circulation During ImmobilityNewsJul.03,2025

-

The Climate-Adaptive Sleep Revolution: Exploring the Benefits of Cooling Gel Memory Foam MattressesNewsJul.03,2025

-

Exploration of the Role of Coconut Foam Mattress in Preventing Bedsores in the ElderlyNewsJul.03,2025

-

Comparing Wave Mattress and Air Mattress: Which Is Better for Medical Use?NewsJul.03,2025

-

Analysis of Comfort and Environmental Performance of Natural Latex and Coconut Foam MattressNewsJul.03,2025

-

Multi-Layer Construction for Enhanced Performance in Gel Mattress PadNewsJun.24,2025