Custom Foam Cutting Services for Perfectly Sized Solutions Tailored to Your Needs

The Benefits of Foam Custom Cut Solutions

In today's fast-paced world, customization is becoming increasingly essential across various industries. Whether in packaging, construction, or creative projects, the need for tailored solutions is paramount. One such solution that has gained considerable popularity is foam custom cut products. Foam, with its plethora of applications, offers unique advantages that cater specifically to individual requirements.

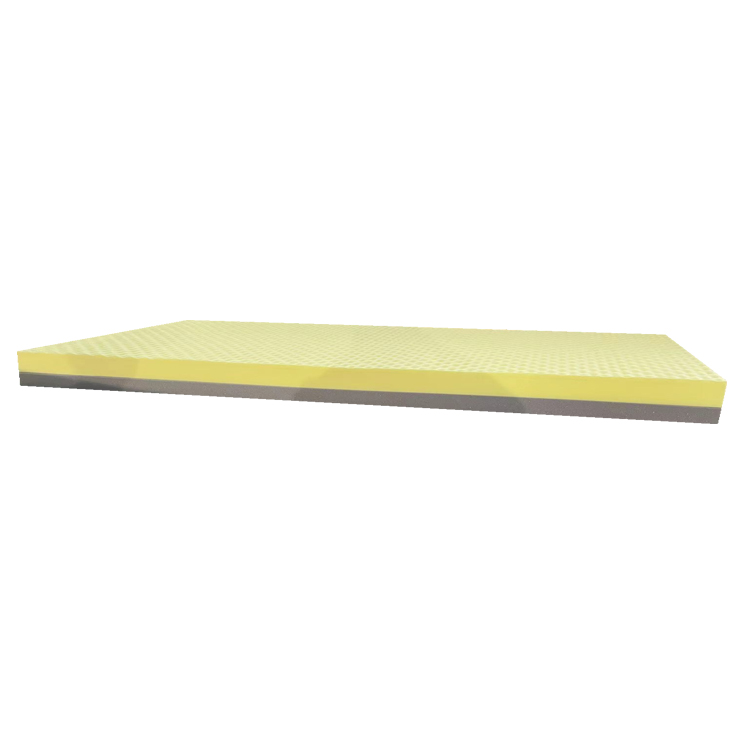

Foam custom cutting refers to the process of designing and shaping foam materials to fit particular specifications. This can range from protective packaging for delicate items to bespoke pieces for artistic projects or even specialized insulation in construction. The flexibility in design makes foam a go-to material for many professionals and businesses.

One of the primary benefits of foam custom cut products is their versatility. Foam comes in various densities, colors, and types, allowing manufacturers to produce tailored solutions for any application. For instance, a company needing protective packaging for fragile electronics could opt for a high-density foam that absorbs shocks and prevents damage during transport. On the other hand, artists or DIY enthusiasts might require softer, more malleable foam for creative projects, allowing for easier manipulation and cutting.

Another significant advantage is cost-effectiveness. Custom-cut foam can be a more economical choice compared to standard solutions. Businesses often find that ordering foam in bulk and having it cut to specific dimensions can save on material costs and reduce waste. Moreover, custom foams provide a perfect fit, minimizing the need for additional protective materials. This precise fit can significantly enhance the efficiency of operations, translating to reduced labor and shipping costs.

foam custom cut

Health and safety considerations also come into play when discussing foam custom cuts

. Many industries are governed by strict safety regulations, especially in sectors like furniture or automotive manufacturing. Custom-cut foam can be designed to comply with these regulations, including fire-retardant properties, damage resistance, or even bacterial resistance. This ensures not only the safety of products but also peace of mind for manufacturers and consumers alike.Furthermore, foam custom cuts lead to improved aesthetics. In the furniture and design sectors, the visual appeal of a product can be as important as its functionality. Custom foam can be tailored to fit unique shapes and patterns, enhancing the overall design of a product. For example, custom-cut foam can play a significant role in interior design, offering personalized solutions for upholstery, cushioning, and decorative accents, thus ensuring that a space reflects the desired style and comfort levels.

In addition, the production of custom-cut foam often leads to reduced environmental impact. Many foam manufacturers are now adopting more sustainable practices by using eco-friendly materials and minimizing waste during the cutting process. By opting for foam that's custom cut, businesses can align their operations with environmental initiatives, contributing to a more sustainable future.

Lastly, the ability to create tailored solutions quickly is another aspect where foam custom cuts shine. With advancements in technology, the process of cutting foam to specific shapes and sizes has become more streamlined and efficient. This agility allows businesses to respond rapidly to changing market demands or unique customer requests, thereby fostering better customer relationships and satisfaction.

In conclusion, foam custom cut solutions present a wealth of benefits across numerous industries. Their versatility, cost-effectiveness, safety compliance, aesthetic enhancement, environmental friendliness, and quick turnaround times make them an indispensable choice for professionals seeking customized solutions. As the trend towards personalization continues to grow, foam custom cuts will undoubtedly remain at the forefront, offering innovative paths to meet the unique demands of any project.

-

The Science Behind Silicon Mattresses for Critical Care EnvironmentsNewsJul.16,2025

-

The Role of Wave Mattress Systems in Pressure Ulcer PreventionNewsJul.16,2025

-

The Role of ICU Nursing Silicon Mattress in Preventing Pressure UlcersNewsJul.16,2025

-

Long-Term Bedridden Patients and the Advantages of Silicon Mattresses in the ICUNewsJul.16,2025

-

From ICU to Home Care: Expanding the Use of Silicon Mattresses for Nursing NeedsNewsJul.16,2025

-

Choosing the Right Wave Mattress for Different Levels of Patient CareNewsJul.16,2025

-

The Effect of Coconut Foam Mattress Breathability and Humidity Regulation on Improving Sleep QualityNewsJul.03,2025