anti pressure sore mattress factories

The Importance of Anti-Pressure Sore Mattresses A Look at Factory Innovations

In today's healthcare landscape, the significance of comfort and patient care cannot be overstated, especially for those who are immobilized or have limited mobility. One crucial element in preventing pressure sores, also known as bedsores or pressure ulcers, is the mattress on which a patient lies. This has led to a burgeoning industry of anti-pressure sore mattress factories that prioritize innovation, comfort, and patient safety.

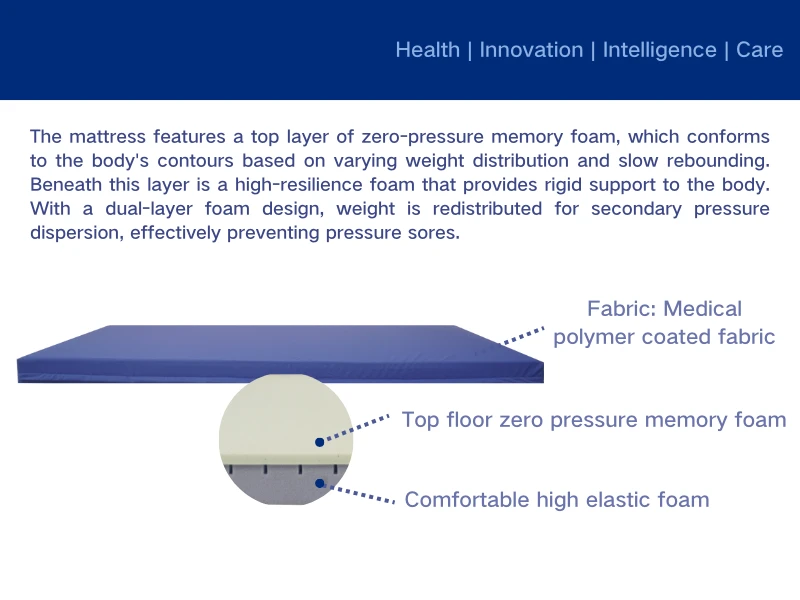

Pressure sores develop due to prolonged pressure on the skin, typically over bony areas like the hips, heels, and back. These injuries can cause significant pain and lead to serious infections if not addressed promptly. Consequently, the demand for specialized mattresses to alleviate this issue has grown. Anti-pressure sore mattress factories have emerged to meet this pressing need, employing advanced materials and technologies designed to alleviate pressure and redistribute weight evenly.

The Importance of Anti-Pressure Sore Mattresses A Look at Factory Innovations

Furthermore, many factories are now focusing on developing dynamic or alternating pressure mattresses. These mattresses come equipped with air chambers that inflate and deflate in a controlled sequence. By regularly changing the contact points between the mattress and the patient's body, these mattresses effectively minimize pressure build-up, drastically reducing the likelihood of sores developing. The adaptability of these dynamic systems is particularly beneficial for patients with varying needs, such as those recovering from surgery or suffering from chronic conditions.

anti pressure sore mattress factories

In addition to materials and technologies, anti-pressure sore mattress factories are integrating user-friendly designs. For example, mattresses are being produced with washable, waterproof covers to enhance hygiene and ease of maintenance. This is especially important in healthcare environments where infection control is paramount. The ease of cleaning and managing these mattresses allows caregivers to maintain a more sanitary environment, reducing the risk of introducing pathogens that can lead to complications.

Beyond the technical aspects, factory production practices are also evolving. An increasing emphasis is placed on sustainable practices and materials. Manufacturers are exploring eco-friendly options, such as organic foams and biodegradable materials, to produce mattresses that are not only effective but also environmentally responsible. This shift not only aligns with the growing consumer demand for sustainable products but also helps to reduce the ecological footprint of the healthcare industry.

Moreover, the growth of anti-pressure sore mattress factories contributes significantly to the economy. By creating jobs and engaging in innovative research and development, these factories not only improve patient care but also stimulate local economies. As healthcare systems worldwide continue to adapt to the needs of aging populations and increasing chronic health issues, the role of these specialized factories will only become more prominent.

In conclusion, anti-pressure sore mattress factories play a vital role in advancing patient comfort and safety in healthcare. Through innovative materials, dynamic pressure redistribution systems, user-friendly designs, and sustainable practices, these factories are at the forefront of addressing a critical aspect of patient care. As technology advances and the need for effective healthcare solutions grows, the contributions of these factories will be essential in preventing pressure sores and enhancing the overall quality of care for vulnerable populations.

-

The Effect of Coconut Foam Mattress Breathability and Humidity Regulation on Improving Sleep QualityNewsJul.03,2025

-

How Wave Mattress Systems Improve Blood Circulation During ImmobilityNewsJul.03,2025

-

The Climate-Adaptive Sleep Revolution: Exploring the Benefits of Cooling Gel Memory Foam MattressesNewsJul.03,2025

-

Exploration of the Role of Coconut Foam Mattress in Preventing Bedsores in the ElderlyNewsJul.03,2025

-

Comparing Wave Mattress and Air Mattress: Which Is Better for Medical Use?NewsJul.03,2025

-

Analysis of Comfort and Environmental Performance of Natural Latex and Coconut Foam MattressNewsJul.03,2025

-

Multi-Layer Construction for Enhanced Performance in Gel Mattress PadNewsJun.24,2025