Factors to Consider When Choosing Anti-Decubitus Mattress Manufacturers

The Importance of Anti-Decubitus Mattresses A Look into the Manufacturing Sector

In the realm of healthcare and patient comfort, anti-decubitus mattresses play a crucial role in preventing pressure ulcers, commonly known as bedsores. These mattresses are designed to redistribute body weight evenly, reducing pressure on vulnerable areas of the skin. As the aging population increases and hospital stays lengthen, the demand for these specialized mattresses has surged, leading to a rise in factories dedicated to their production. This article explores the significance of anti-decubitus mattresses, the manufacturing processes involved, and the key players in this essential industry.

Understanding Anti-Decubitus Mattresses

Anti-decubitus mattresses are specifically engineered to support individuals who are immobile or have limited mobility. Bedsores can develop when pressure is consistently applied to the skin, leading to tissue breakdown. These mattresses employ various technologies, including air, gel, or foam, to alleviate pressure points and promote circulation. Their primary purpose is to enhance patient comfort while significantly reducing the risk of developing pressure ulcers, which can complicate recovery and extend hospital stays.

The Manufacturing Process

The production of anti-decubitus mattresses involves several intricate processes, ensuring that the final product meets the highest standards of quality and functionality. The key steps in manufacturing include

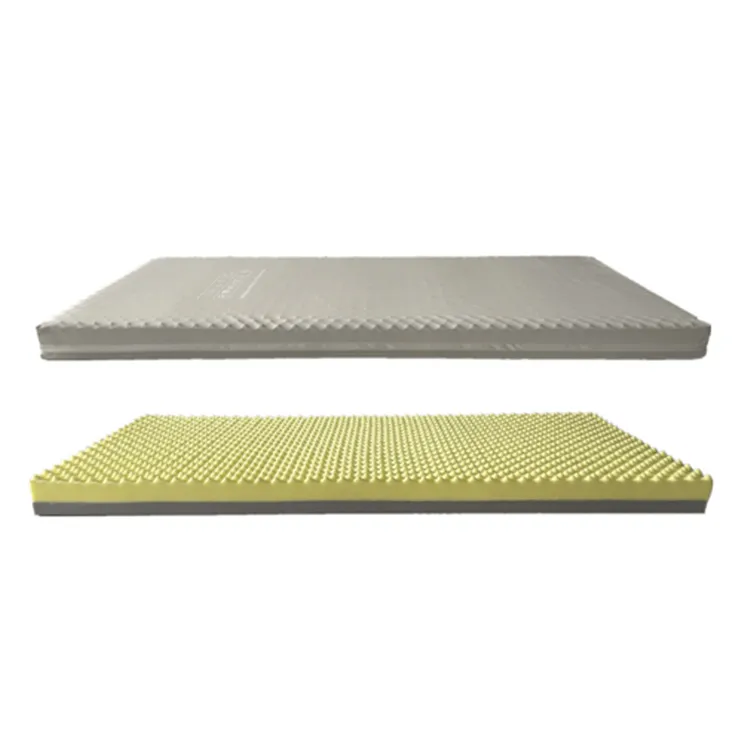

1. Material Selection High-quality materials are crucial in the construction of anti-decubitus mattresses. Commonly used materials include high-density foam, memory foam, gel inserts, and air-filled chambers. Each material has unique properties that contribute to pressure relief, breathability, and durability.

2. Design and Engineering Manufacturers invest heavily in research and development to create mattress designs that maximize therapeutic benefits. This includes contouring to the body, creating adjustable pressure zones, and ensuring that the mattress is easy to clean and maintain.

3. Production Techniques The manufacturing process may involve advanced techniques such as cutting-edge molding, layering, and stitching. Automation is becoming increasingly integrated into these factories, allowing for greater precision and efficiency in the production line.

anti-decubitus mattress factories

4. Quality Control Rigorous testing is essential to ensure that each mattress performs as intended. Factors such as weight distribution, durability, and ease of use are thoroughly evaluated before the product reaches the market. Compliance with health standards and certifications is also a critical aspect of quality assurance.

5. Distribution and Supply Chain Management Once manufactured, anti-decubitus mattresses need to be efficiently distributed to healthcare facilities, nursing homes, and individual consumers. Effective supply chain management ensures that products are available when and where they are needed, particularly in acute care settings.

Key Players in the Industry

The anti-decubitus mattress manufacturing industry includes a diverse range of companies, from large multinational corporations to specialized local manufacturers. Leading companies often invest in innovation and research, collaborating with healthcare professionals to improve mattress designs and materials continually. They also participate in educational programs to raise awareness about the prevention of pressure ulcers and the importance of proper mattress selection.

Additional players in the marketplace include wholesalers and distributors who facilitate access to these essential products. As hospitals and care facilities strive to offer the best patient care, the demand for quality anti-decubitus mattresses continues to grow, ultimately driving competition and innovation within the industry.

Conclusion

The role of anti-decubitus mattresses in healthcare is indispensable, particularly as the population ages and the prevalence of conditions requiring prolonged bed rest increases. Factories dedicated to producing these mattresses are at the forefront of ensuring patient safety and comfort. The manufacturing processes, innovative designs, and quality control measures contribute significantly to developing products that can genuinely impact patient outcomes.

As the healthcare landscape evolves, so too will the technologies and manufacturing processes behind anti-decubitus mattresses. By continuing to prioritize research, quality, and patient safety, manufacturers can help mitigate the risks of pressure ulcers and enhance the overall well-being of individuals in care. The journey from factory to bedside is a testament to the commitment of the industry to support health and recovery across the globe.

-

The Science Behind Silicon Mattresses for Critical Care EnvironmentsNewsJul.16,2025

-

The Role of Wave Mattress Systems in Pressure Ulcer PreventionNewsJul.16,2025

-

The Role of ICU Nursing Silicon Mattress in Preventing Pressure UlcersNewsJul.16,2025

-

Long-Term Bedridden Patients and the Advantages of Silicon Mattresses in the ICUNewsJul.16,2025

-

From ICU to Home Care: Expanding the Use of Silicon Mattresses for Nursing NeedsNewsJul.16,2025

-

Choosing the Right Wave Mattress for Different Levels of Patient CareNewsJul.16,2025

-

The Effect of Coconut Foam Mattress Breathability and Humidity Regulation on Improving Sleep QualityNewsJul.03,2025