anti-decubitus mattress factories

Understanding Anti-Decubitus Mattress Factories

Anti-decubitus mattress factories play a crucial role in the healthcare sector, particularly in the prevention and management of pressure ulcers, also known as bedsores. These specialized mattresses are designed to provide comfort and support for individuals who are bedridden or have limited mobility, reducing the risk of skin damage caused by prolonged pressure.

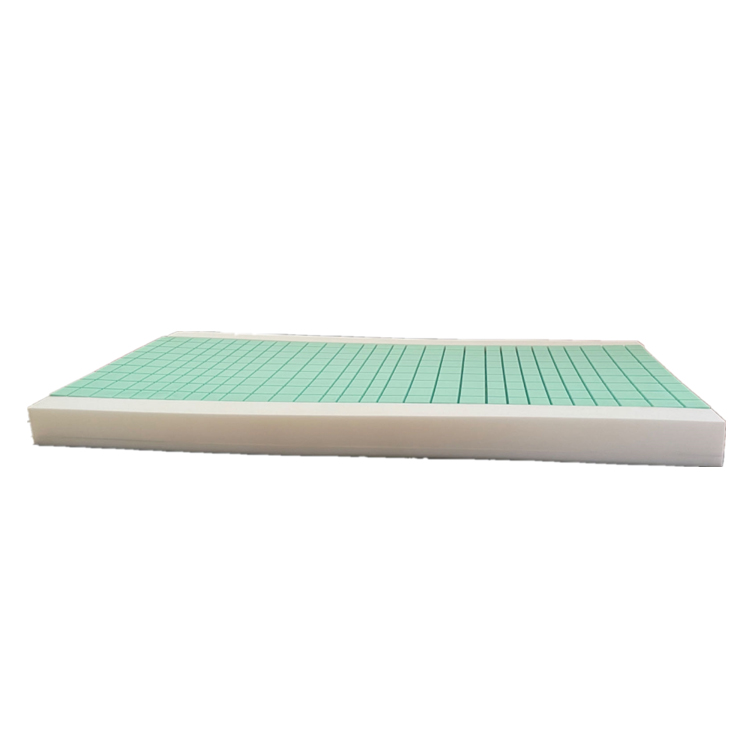

Pressure ulcers develop when there is sustained pressure on the skin, often affecting areas over bony prominences. Anti-decubitus mattresses are engineered with unique materials and technologies to distribute body weight evenly and promote blood circulation. Factories producing these mattresses utilize a variety of designs, including air-filled, foam, and gel solutions, each with its benefits tailored to specific patient needs.

The production process in anti-decubitus mattress factories involves several key steps, starting with the selection of high-quality materials

. Many manufacturers focus on breathable, hypoallergenic, and moisture-wicking fabrics to enhance comfort and reduce the risk of skin irritation. Additionally, the internal structures of the mattresses are meticulously designed to ensure optimal pressure relief and support.anti-decubitus mattress factories

Quality control is paramount in these factories. Manufacturers often conduct rigorous testing to ensure their products meet stringent health and safety standards. This includes verifying the durability of materials, the effectiveness of pressure distribution, and the overall performance of the mattress under various conditions.

Moreover, the rise of technology in healthcare has led to innovative advancements in anti-decubitus mattresses. Smart mattresses equipped with sensors that monitor pressure points are becoming increasingly common. These high-tech features provide real-time data, allowing caregivers to make informed decisions to enhance patient care.

Sustainability is another growing concern in the industry. Many anti-decubitus mattress factories are exploring eco-friendly materials and processes to minimize their environmental impact. This includes the use of recycled materials in mattress construction and the implementation of energy-efficient manufacturing practices.

In conclusion, anti-decubitus mattress factories are essential in the fight against pressure ulcers, contributing to patient comfort and overall well-being. By combining advanced materials, innovative technologies, and sustainable practices, these manufacturers are improving the quality of life for countless individuals in need of specialized healthcare solutions. As the demand for effective, comfortable, and environmentally conscious products continues to grow, anti-decubitus mattress factories remain at the forefront of healthcare innovation.

-

The Effect of Coconut Foam Mattress Breathability and Humidity Regulation on Improving Sleep QualityNewsJul.03,2025

-

How Wave Mattress Systems Improve Blood Circulation During ImmobilityNewsJul.03,2025

-

The Climate-Adaptive Sleep Revolution: Exploring the Benefits of Cooling Gel Memory Foam MattressesNewsJul.03,2025

-

Exploration of the Role of Coconut Foam Mattress in Preventing Bedsores in the ElderlyNewsJul.03,2025

-

Comparing Wave Mattress and Air Mattress: Which Is Better for Medical Use?NewsJul.03,2025

-

Analysis of Comfort and Environmental Performance of Natural Latex and Coconut Foam MattressNewsJul.03,2025

-

Multi-Layer Construction for Enhanced Performance in Gel Mattress PadNewsJun.24,2025