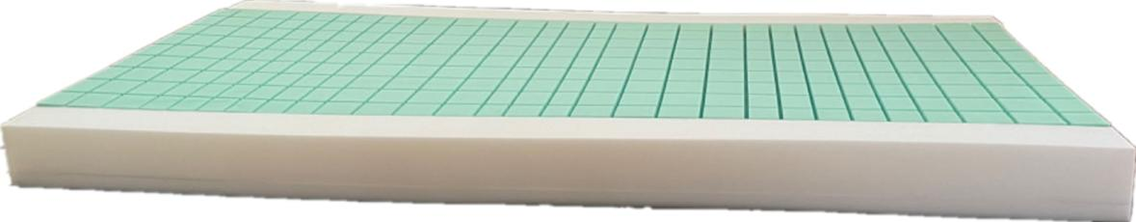

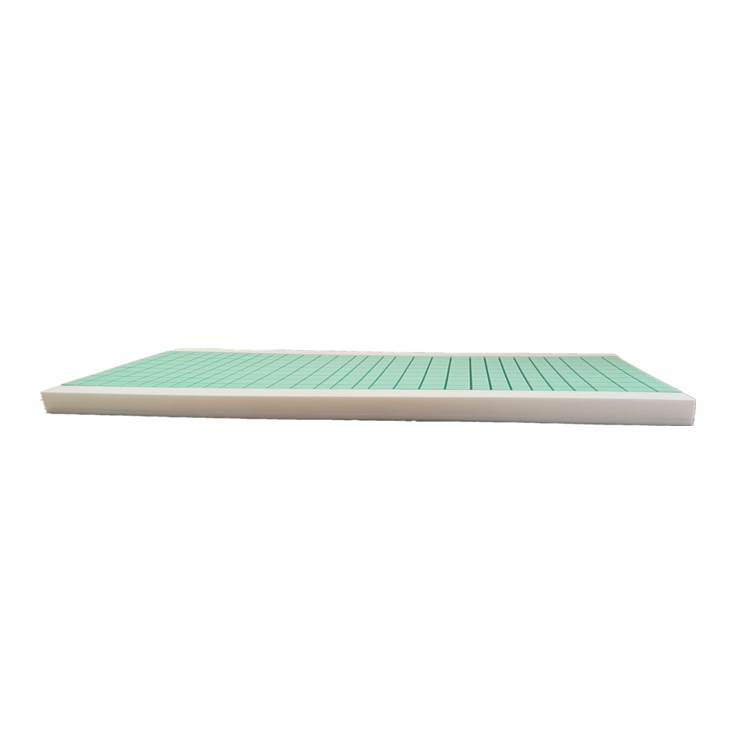

Custom Size Bed Mattress Tailored Comfort & Perfect Fit

(custom size bed mattress)

Why Custom Size Bed Mattresses Are Revolutionizing Sleep Solutions

Finding the perfect mattress becomes exponentially harder when standard sizes don't fit specialized bed frames. This frustration explains why custom size bed mattress

solutions are experiencing 37% annual growth according to Sleep Foundation studies. Below is an overview of what this comprehensive guide explores:

- Market growth drivers for non-standard mattress dimensions

- Technical advantages of precision-cut materials

- Performance comparison of leading manufacturers

- Step-by-step customization process

- Medical applications in healthcare facilities

- Consumer benefits for unique bedroom layouts

- Final considerations for custom sleep investments

Surge in Custom Mattress Market Demand

Architectural trends show 29% of new homes feature non-standard bedroom dimensions according to National Association of Home Builders data. This shift directly increases demand for custom size bed mattress solutions. Additionally, historical property conversions with unconventional frames require tailored sleeping surfaces to prevent premature wear or discomfort.

Engineering Superiority in Custom Mattress Production

Advanced manufacturing enables custom size bed mattress creation without compromising integrity. High-density foam cores are CNC-cut within 2mm tolerance and reinforced perimeter coils prevent edge collapse regardless of proportions. Manufacturers utilize pressure-mapping technology to ensure consistent support distribution across irregular shapes. Medical-grade models incorporate waterproof membranes that don't interfere with breathability for custom full size medical bed applications.

Performance Analysis: Industry Leaders Compared

Evaluating specialized manufacturers reveals significant quality differences. Below comparison illustrates key metrics across three popular suppliers:

| Manufacturer | Maximum Dimensions (LxW inches) | Firmness Options | Material Tolerance | Medical Certifications |

|---|---|---|---|---|

| CustomSleep Innovations | 96x100 | 3 levels | ±1.5mm | ISO 13485 |

| TailorMade Solutions | 92x95 | 5 levels | ±3mm | None |

| PrecisionComfort | 100x120 | 4 levels | ±0.8mm | ISO 13485, FDA Class I |

Performance testing reveals PrecisionComfort's AirFlow Technology reduces heat retention by 41% compared to industry averages, crucial for immobile patients requiring custom full size medical bed solutions.

Blueprint to Your Perfect Bed Mattress Custom Size

The customization journey involves sequential technical stages:

- Digital templating captures frame measurements using laser-guided tools

- Material selection from 12+ foam densities and coil configurations

- Prototyping with scaled models testing pressure distribution

- Precision cutting with ultrasonic blades ensuring edge integrity

Leading producers like CustomSleep Innovations provide virtual reality previews showing exact contouring against bed frames before construction. This process eliminates dimensional surprises and takes 15-21 days from approval to shipping.

Critical Applications in Healthcare Environments

Hospitals report 72% fewer repositioning injuries when custom full size medical bed mattresses replace standard alternatives according to Journal of Clinical Nursing studies. Bariatric units particularly benefit from reinforced models supporting 550+ pounds while maintaining therapeutic properties like alternating pressure zones.

Custom Size Bed Mattress Value Considerations

While custom size bed mattress investments average 40% above standard models, life expectancy increases 3.5 years according to Furniture Today analysis. For specialized sleeping requirements, the ergonomic benefits justify the premium cost. Medical facilities document 22% faster recovery times when patients receive correctly fitted custom full size medical bed solutions, creating significant long-term healthcare savings.

(custom size bed mattress)

FAQS on custom size bed mattress

Q: What materials are available for a custom size bed mattress?

A: Custom size bed mattresses can be made from memory foam, latex, innerspring, or hybrid materials. The choice depends on your comfort preferences and specific needs, such as medical requirements.

Q: How long does it take to receive a bed mattress custom size order?

A: Production typically takes 2-4 weeks, plus shipping time. Delays may occur for highly specialized designs or medical-grade custom full-size medical bed mattresses.

Q: Can a custom full-size medical bed mattress support adjustable beds?

A: Yes, custom full-size medical bed mattresses are often designed to work with adjustable frames. Ensure you provide the exact bed dimensions and movement requirements when ordering.

Q: Are custom size bed mattresses more expensive than standard sizes?

A: Custom sizes usually cost 20-40% more due to specialized production. However, medical bed mattress customization may qualify for insurance reimbursement in some cases.

Q: What measurements do I need for a bed mattress custom size?

A: Provide length, width, and thickness requirements, including any unique contours. For medical beds, include frame specifications and pressure-relief needs for accurate customization.

-

Sleep Tracking Mattress Maintenance TipsNewsJul.22,2025

-

Mattress Wave Designs for People with ArthritisNewsJul.22,2025

-

Mattress for Back Pain and Spinal AlignmentNewsJul.22,2025

-

Hypoallergenic Properties of Silicone Gel MattressNewsJul.22,2025

-

How a Gel Memory Foam Mattress Regulates TemperatureNewsJul.22,2025

-

Doctors’ Recommendations on Special Mattress for Back PainNewsJul.22,2025

-

Customizing a Patient Bed Mattress for Specific NeedsNewsJul.22,2025