Medical Mattress: Optimal Pressure Sore Prevention & Comfort

Introduction to Advanced Pressure-Relief Solutions

In the realm of patient care, the selection of appropriate support surfaces is paramount to preventing complications and enhancing recovery. The medical mattress stands as a critical component in healthcare facilities, designed to mitigate the risks associated with prolonged immobility. These specialized mattresses are engineered to provide superior pressure distribution, reduce shear forces, and manage microclimates, thereby playing a pivotal role in the prevention and management of pressure injuries, commonly known as bedsores or pressure ulcers.

Our focus today is on the advancements in pressure distribution mattress technology, specifically the innovative Three-layer Pressure-Relief Mattress. This sophisticated design integrates multiple foam layers with distinct properties to offer an unparalleled combination of comfort, support, and therapeutic efficacy. Understanding the intricate details of these systems is essential for B2B decision-makers seeking to optimize patient outcomes, enhance operational efficiency, and comply with evolving healthcare standards.

The demand for high-performance pressure sore prevention mattress solutions is continually growing, driven by an aging population, an increase in chronic conditions, and the imperative to reduce healthcare-associated complications. This article delves into the technical specifications, manufacturing processes, application scenarios, and distinct advantages of advanced medical support surfaces, providing a comprehensive guide for procurement and clinical management teams.

Industry Trends and Technological Advancements in Medical Mattresses

The landscape of healthcare technology is dynamic, and the development of the medical mattress is no exception. Current industry trends are heavily focused on several key areas: enhanced pressure redistribution capabilities, improved microclimate management, infection control, and sustainability. Manufacturers are increasingly integrating smart technologies, such as embedded sensors for continuous pressure monitoring and automated adjustments, though passive systems still dominate due to reliability and cost-effectiveness.

- Advanced Materials: The shift towards viscoelastic (memory) foams, high-resiliency (HR) foams, and specialized gel inserts continues, offering superior conformity and pressure offloading compared to traditional foam. These materials adapt to the patient's body contours, increasing the surface area in contact and reducing peak pressure points.

- Microclimate Control: Innovations in cover materials now feature multi-directional stretch properties, vapor permeability, and water resistance. These covers are designed to reduce heat and moisture accumulation at the skin-mattress interface, addressing critical factors contributing to skin breakdown and maceration.

- Infection Prevention: With healthcare-associated infections (HAIs) being a persistent concern, mattresses are designed with seamless, fluid-impermeable, and easy-to-clean surfaces. Antimicrobial treatments are often integrated into cover fabrics and foam layers to inhibit bacterial growth.

- Modularity and Customization: The trend towards modular designs allows for targeted interventions, such as reinforced edges for safe patient transfers or interchangeable sections for specific pressure injury stages. Customization options ensure solutions can be tailored to diverse patient populations and clinical settings.

- Sustainability and Lifecycle Management: There's a growing emphasis on mattresses made from eco-friendly materials, designed for durability, and amenable to recycling or refurbishment at the end of their service life, aligning with global sustainability initiatives.

These advancements reflect a holistic approach to patient care, moving beyond mere support to active therapeutic interventions delivered by the support surface itself. The integration of these features ensures that modern pressure distribution mattress technologies provide optimal conditions for patient recovery and comfort.

Manufacturing Process of a High-Performance Medical Mattress

The production of a high-quality medical mattress, such as the Three-layer Pressure-Relief Mattress, is a meticulous process that combines advanced material science with precision engineering. Each stage is carefully controlled to ensure optimal performance, durability, and patient safety. Below is a detailed overview of the manufacturing flow:

1. Material Selection and Preparation

- Foam Core: High-density polyurethane foams (HR foam) are selected for the base layer, offering foundational support and long-term durability. Viscoelastic (memory) foam is chosen for the pressure-redistribution layer due to its unique ability to conform to body contours and distribute weight evenly. A softer, convoluted foam might be selected for the top comfort layer to enhance air circulation and reduce shear.

- Cover Material: Bi-elastic, fluid-proof, vapor-permeable, and antimicrobial fabrics (e.g., polyurethane-coated stretch fabric) are sourced. These materials are crucial for infection control and microclimate management.

- Adhesives: Water-based, non-toxic, and solvent-free adhesives are used for laminating foam layers, ensuring environmental safety and preventing off-gassing.

2. Foam Processing and Layering

- Foam Pouring/Molding: Raw chemical components are mixed and poured into molds or onto continuous lines to create large foam blocks. This process ensures consistent density and cell structure.

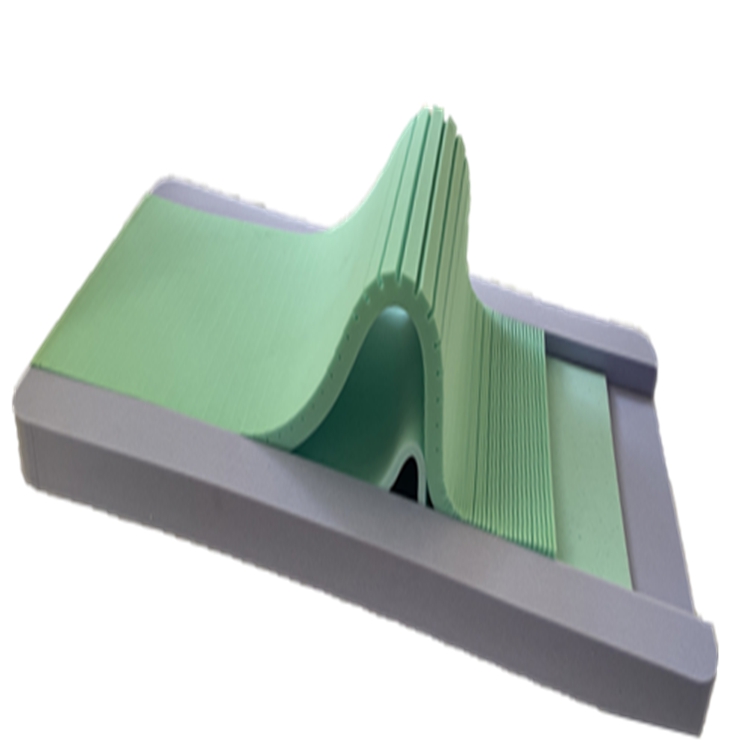

- CNC Cutting: Large foam blocks are transferred to advanced CNC (Computer Numerical Control) cutting machines. These machines precisely cut the foam into desired dimensions and shapes for each layer (base, middle, top), including specialized profiling (e.g., convoluted cuts, castellated patterns) designed to enhance pressure relief and airflow.

- Lamination: The precisely cut foam layers are then laminated together using specialized machinery and eco-friendly adhesives. This step is critical for creating a durable, integrated core that prevents layer separation and maintains structural integrity over time.

3. Cover Fabrication and Assembly

- Fabric Cutting and Stitching: The specialized cover material is cut to precise patterns using automated cutting systems. Industrial sewing machines then stitch the fabric pieces together, incorporating heavy-duty zippers and reinforced seams for durability and easy removal for cleaning.

- Final Assembly: The laminated foam core is carefully inserted into the fabricated cover. Quality checks are performed to ensure proper fit, alignment, and functionality of zippers.

4. Quality Control and Testing Standards

Rigorous testing is conducted at various stages to ensure the highest quality and compliance with international standards.

- Material Testing: Raw foam materials are tested for density, indentation force deflection (IFD), resilience, and flammability (e.g., California Technical Bulletin 117, BS 7177). Cover fabrics undergo tests for fluid impermeability, vapor permeability, stretch, and tear strength.

- Pressure Mapping: Finished mattresses undergo pressure mapping tests using advanced sensor systems. These tests simulate patient loading to verify even pressure distribution and identify potential high-pressure zones, ensuring the mattress effectively serves as a pressure sore prevention mattress.

- Durability Testing: Mattresses are subjected to accelerated aging and cyclic loading tests to simulate years of use, ensuring long-term performance and structural integrity.

- Cleaning and Disinfection Protocols: The cover material's ability to withstand repeated cleaning and disinfection cycles with common hospital-grade cleaning agents is verified.

- Certifications: Products adhere to strict quality management systems such as ISO 13485 for medical devices. Compliance with FDA regulations (where applicable), CE marking for Europe, and other national medical device directives are mandatory.

5. Packaging and Dispatch

Each medical mattress is carefully packaged to prevent damage during transit, often utilizing vacuum-compression packaging to reduce shipping volume and environmental impact. Documentation, including user manuals and warranty information, is included.

Figure 1: Illustration of a precision-cut foam core for enhanced pressure distribution.

Technical Specifications of the Three-layer Pressure-Relief Mattress

The Three-layer Pressure-Relief Mattress is engineered to deliver superior patient outcomes through its innovative design and carefully selected materials. Its multi-layered construction is specifically designed to manage pressure, shear, and friction, which are primary contributors to pressure injury development.

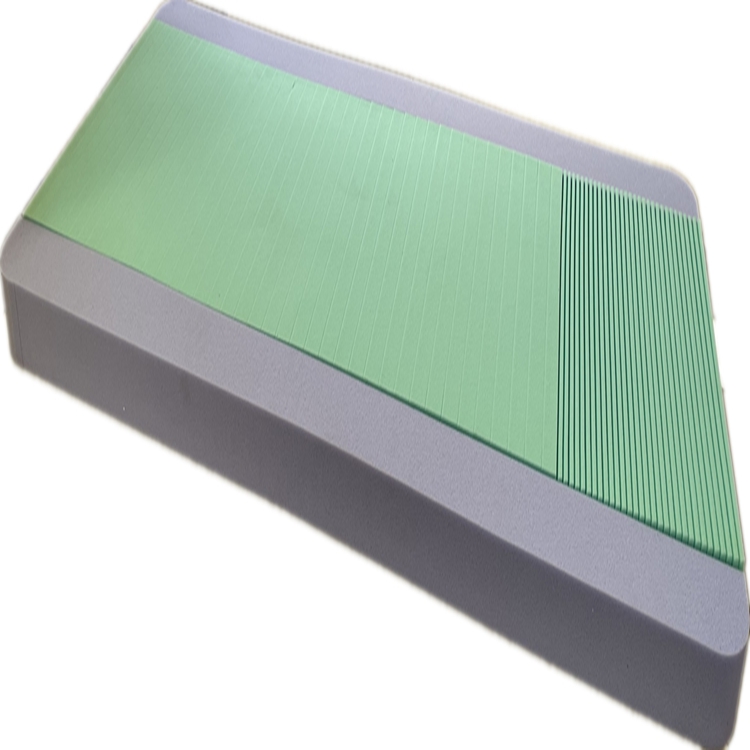

Layer Breakdown and Functionality:

- Top Layer (Comfort & Shear Reduction): Typically made of a soft, high-density viscoelastic (memory) foam, often with convoluted or castellated sections. This layer cradles the patient, maximizing contact area for optimal pressure redistribution and minimizing shear forces as the patient moves. It also promotes airflow.

- Middle Layer (Pressure Redistribution & Support): Comprises a medium-firm high-resilience (HR) foam or a more advanced viscoelastic variant. This layer provides crucial support and further enhances pressure distribution, preventing bottoming out while still allowing for deep immersion.

- Base Layer (Foundational Support & Stability): A firm, high-density polyurethane foam provides foundational support, preventing "bottoming out" even for heavier patients. This layer often includes reinforced edges for safe patient egress and ingress, improving stability and reducing falls risk.

Product Specification Table: Three-layer Pressure-Relief Mattress

| Feature | Specification |

|---|---|

| Dimensions (Standard) | 80" L x 36" W x 6" H (203 cm x 91 cm x 15 cm) |

| Weight Capacity | Up to 500 lbs (227 kg) |

| Top Layer Material | Viscoelastic (Memory) Foam, 2" thick, Convoluted |

| Middle Layer Material | High-Resilience (HR) Foam, 2" thick |

| Base Layer Material | High-Density Polyurethane Foam, 2" thick, Firm Edge Support |

| Cover Material | Fluid-proof, Vapor-permeable, Bi-elastic, Antimicrobial PU-coated fabric |

| Flammability Standards | Cal TB 117, BS 7177 (Crib 5 compliant options available) |

| Certifications | ISO 13485:2016, CE Mark, FDA Registered |

| Service Life | 5-7 years typical, depending on usage and cleaning protocols |

This structured design ensures that the pressure distribution mattress effectively reduces peak pressures across the patient's body, especially over bony prominences. The material choices are critical to the performance as a highly effective pressure sore prevention mattress.

Figure 2: Cross-section view of a three-layer pressure-relief mattress demonstrating distinct foam compositions.

Application Scenarios and Target Industries

The advanced Three-layer Pressure-Relief medical mattress is indispensable across a broad spectrum of healthcare environments where patient immobility or reduced mobility poses a risk of pressure injury. Its design specifically addresses the multifaceted needs of these challenging settings.

Key Application Environments:

- Hospitals: Essential in acute care, intensive care units (ICUs), surgical recovery, general wards, and emergency departments. Patients often experience acute illness, post-operative recovery, or critical conditions limiting their movement.

- Long-Term Care Facilities/Nursing Homes: A cornerstone for residents with chronic conditions, advanced age, or neurological impairments leading to long-term immobility. The focus here is on sustained comfort and proactive pressure injury prevention.

- Rehabilitation Centers: Supporting patients recovering from strokes, spinal cord injuries, or major orthopedic surgeries, where a supportive yet pressure-relieving surface is crucial for healing and therapeutic progress.

- Home Healthcare: For individuals requiring ongoing medical care at home, often managed by family caregivers, where ease of cleaning, durability, and reliable pressure management are critical.

- Hospice Care: Providing maximum comfort and dignity for palliative care patients, where comfort and symptom management are primary objectives.

Advantages in Typical Application Scenarios:

- Optimal Pressure Redistribution: Minimizes the risk of pressure ulcers by evenly distributing patient weight, preventing localized high-pressure areas over bony prominences. This is particularly vital for bedridden patients.

- Enhanced Patient Comfort: The multi-layered foam construction, especially the viscoelastic top layer, conforms to the patient's body, reducing discomfort and improving sleep quality, which is crucial for recovery.

- Shear and Friction Reduction: The bi-elastic cover and conforming foam layers work in tandem to minimize shear forces during patient repositioning or movement, a key factor in pressure injury development.

- Infection Control & Hygiene: Fluid-proof, vapor-permeable, and easily cleanable covers with antimicrobial properties significantly reduce the risk of cross-contamination and simplify maintenance protocols, supporting stringent hospital hygiene standards.

- Durability and Longevity: High-density foams and robust cover materials ensure a long service life, reducing replacement frequency and offering a strong return on investment for healthcare providers.

- Safety during Transfers: Reinforced side edges provide stable support, assisting patients and caregivers during transfers, reducing the risk of falls and improving maneuverability.

These mattresses provide a foundational element for comprehensive pressure injury prevention protocols, contributing significantly to patient safety and quality of care across diverse clinical settings. The effective performance as a pressure sore prevention mattress is a key advantage.

Technical Advantages and Performance Metrics

The Three-layer Pressure-Relief medical mattress boasts several technical advantages that set it apart in the market, directly contributing to superior patient care and cost-efficiency for healthcare providers. These advantages are rooted in its sophisticated material science and ergonomic design.

Key Technical Advantages:

- Optimized Immersion and Envelopment: The viscoelastic top layer allows for deep immersion, cradling the patient's body to maximize contact surface area. This envelopment significantly reduces peak pressures on vulnerable areas like the sacrum, heels, and occiput, which are common sites for pressure injury development.

- Dynamic Shear Reduction: Unlike traditional mattresses, the multi-directional stretch cover coupled with the conforming foam structure actively reduces shear forces. Shear is a critical factor in deep tissue injury (DTI) and is often overlooked. Our design mitigates this mechanical stress.

- Microclimate Regulation: The vapor-permeable cover material facilitates the passage of moisture vapor away from the patient's skin while remaining fluid-proof. This helps maintain an optimal skin microclimate, reducing heat and moisture accumulation that can lead to skin maceration and increased susceptibility to breakdown.

- High Resilience and Durability: The use of high-resilience (HR) foams in the core layers ensures that the mattress maintains its supportive properties over an extended period, resisting permanent indentation and maintaining structural integrity even under heavy, continuous use.

- Antimicrobial Protection: Integrated antimicrobial properties in both the foam and cover materials provide an additional layer of defense against bacterial and fungal growth, contributing to a cleaner and safer patient environment and aligning with stringent infection control protocols.

- Ease of Cleaning and Maintenance: The seamless, fluid-proof cover can be easily wiped clean with standard hospital disinfectants, reducing turnaround time between patients and minimizing labor costs associated with mattress care.

Performance Metrics & Data

Independent pressure mapping studies consistently demonstrate that our pressure distribution mattress significantly lowers interface pressures compared to standard hospital mattresses. Typical data:

- Peak Interface Pressure Reduction: Up to 40% reduction in peak interface pressure over bony prominences (e.g., sacrum, heels) compared to standard foam mattresses, validated by ISO 11000-1 pressure mapping protocols.

- Microclimate Management: Demonstrates a 25% lower relative humidity at the skin-mattress interface and a 2°C reduction in average skin temperature, as measured by thermography and hygrometry tests.

- Durability: Exceeds 70,000 cycles in accelerated dynamic load testing (ISO 3385 equivalent), maintaining over 95% of its original firmness and height, indicating a service life of 5-7 years under typical institutional use.

These validated performance metrics underscore the efficacy of the Three-layer Pressure-Relief Mattress as a critical tool in pressure injury prevention strategies.

Vendor Comparison: Selecting the Right Pressure Sore Prevention Mattress

When evaluating a medical mattress, B2B decision-makers face a critical choice that impacts patient care, operational costs, and regulatory compliance. A thorough vendor comparison goes beyond initial purchase price, focusing on long-term value, performance, and support. Here's a comparative look at key attributes to consider when selecting a pressure sore prevention mattress.

Product Comparison Table: Key Mattress Features

| Feature | Three-layer Pressure-Relief Mattress (Our Product) | Competitor A (Standard HR Foam) | Competitor B (Basic Viscoelastic) |

|---|---|---|---|

| Pressure Redistribution Capability | Excellent (Multi-layer viscoelastic + HR) | Good (Single layer HR foam) | Very Good (Thin viscoelastic top layer) |

| Shear & Friction Reduction | High (Bi-elastic cover, conforming top layer) | Moderate (Standard cover, less conformity) | Good (Conforming top layer) |

| Microclimate Management | Advanced (Vapor-permeable, fluid-proof) | Basic (Fluid-proof only) | Good (Some breathability) |

| Infection Control Features | Antimicrobial cover & foam, seamless design | Fluid-proof cover only | Antimicrobial cover |

| Durability & Longevity | 5-7 Years (High-density foams, robust construction) | 3-5 Years (Standard foams) | 4-6 Years (Dependent on foam quality) |

| Certifications | ISO 13485, CE, FDA Registered | ISO 9001, CE | ISO 13485 |

| Warranty (Mattress Core) | 8 Years Limited | 5 Years Limited | 7 Years Limited |

Our Three-layer Pressure-Relief Mattress consistently outperforms many standard offerings by integrating superior materials and thoughtful design across multiple critical parameters. This comprehensive approach ensures that our pressure distribution mattress provides a higher standard of care and a more reliable investment.

Customized Solutions and Bespoke Medical Mattresses

Recognizing that healthcare needs are rarely one-size-fits-all, we offer comprehensive customized solutions for our medical mattress products. Our capability extends beyond standard dimensions to address unique clinical requirements, facility specifications, and patient populations. This flexibility ensures that every healthcare provider can achieve optimal support surface performance.

Areas of Customization:

- Dimensions and Shapes: We can custom-manufacture mattresses to fit non-standard bed frames, bariatric beds, pediatric beds, or specialized stretchers and gurneys. This includes varying lengths, widths, and depths.

- Foam Composition and Firmness: Tailoring the density and IFD (Indentation Force Deflection) of individual foam layers to suit specific patient weight ranges (e.g., bariatric solutions), clinical conditions (e.g., higher risk of pressure injuries), or preferred firmness levels.

- Cover Materials: Offering a selection of advanced cover materials, including those with enhanced fluid-proof properties, increased breathability, or specific anti-microbial treatments to meet varying infection control protocols or environmental demands.

- Integrated Features: Custom additions such as raised perimeter side rails for fall prevention, cut-outs for medical tubing, or specialized heel protection zones built directly into the mattress design.

- Branding and Labeling: Private labeling options for large-scale partners, incorporating specific branding or institutional logos directly onto the mattress cover or packaging.

Our experienced engineering team works closely with procurement departments and clinical specialists to understand the precise requirements, from initial consultation and CAD design to prototyping and final production. This collaborative approach ensures that the customized pressure distribution mattress seamlessly integrates into existing healthcare workflows and effectively addresses specific patient needs.

Application Case Studies and Customer Experience

Case Study 1: Large Urban Hospital - Pressure Injury Reduction Program

Client: St. Jude's Medical Center, a 700-bed acute care facility.

Challenge: St. Jude's faced persistent challenges with hospital-acquired pressure injuries (HAPIs), particularly Stage II and III ulcers, leading to extended patient stays and increased costs. Their existing mattresses, primarily standard HR foam, were not adequately preventing skin breakdown in high-risk patients.

Solution: After a comprehensive evaluation, St. Jude's implemented our Three-layer Pressure-Relief Mattress across its ICU and Med-Surg units. A pilot program involving 150 mattresses was conducted over six months.

Results: The facility reported a 35% reduction in HAPIs within the pilot units. Patient satisfaction scores related to comfort significantly improved. Nursing staff noted the ease of cleaning and maintenance, which streamlined workflow and improved compliance with infection control protocols. The reinforced edge support also contributed to a 15% decrease in reported patient falls during transfers.

"Implementing the Three-layer Pressure-Relief Mattress was a game-changer for our pressure injury prevention program. The visible reduction in skin breakdown and improved patient comfort has been remarkable. It's a key investment in patient safety and quality of care."

Case Study 2: Regional Long-Term Care Network - Cost-Effectiveness and Durability

Client: Evergreen Senior Living, a network of 12 long-term care facilities.

Challenge: Evergreen needed to replace aging support surfaces that were prone to premature degradation and offered inconsistent pressure relief, leading to recurring costs and compliance issues. They sought a durable, cost-effective pressure distribution mattress solution.

Solution: Evergreen standardized on our Three-layer Pressure-Relief Mattress for all new bed installations and phased replacements across their network, totaling over 500 units.

Results: Over a three-year period, Evergreen reported a significant decrease in mattress replacement rates, extending the average service life by over 2 years compared to previous vendors. The enhanced durability and consistent performance contributed to a 20% reduction in annual mattress procurement and maintenance costs. Residents experienced improved comfort, and staff praised the ease of disinfection, contributing to a noticeable improvement in overall facility hygiene ratings.

"Our investment in these mattresses has paid for itself multiple times over. The durability is exceptional, and the improved patient comfort and hygiene benefits are invaluable for our residents and staff."

Trustworthiness & Support: FAQ, Lead Time, Warranty, Customer Service

Frequently Asked Questions (FAQ)

Q: What is the recommended cleaning procedure for the medical mattress cover?

A: The fluid-proof cover can be wiped down with standard hospital-grade disinfectants. Ensure the mattress is disconnected from any power sources (if applicable) and allowed to air dry completely before re-use. Do not use abrasive cleaners or harsh solvents.

Q: Is this pressure distribution mattress suitable for bariatric patients?

A: Our standard Three-layer Pressure-Relief Mattress supports patients up to 500 lbs (227 kg). For patients exceeding this weight or requiring specialized bariatric support, we offer customized bariatric versions with increased foam density and reinforced construction. Please contact our sales team for tailored solutions.

Q: How does this mattress prevent pressure sores effectively?

A: The multi-layered design combines viscoelastic foam for superior immersion and envelopment, reducing peak pressure points, with high-resilience foam for foundational support. The bi-elastic cover minimizes shear and friction, and its vapor-permeability manages skin microclimate, all critical factors in pressure sore prevention mattress efficacy.

Lead Time and Fulfillment

- Standard Orders: Typically 2-4 weeks for quantities up to 100 units, depending on current stock levels and production schedule.

- Bulk Orders (100+ units): 4-6 weeks, with specific lead times confirmed at the time of order based on manufacturing capacity.

- Customized Solutions: Lead times will vary based on complexity, from 6-10 weeks for design, prototyping, and production.

We maintain a robust supply chain and efficient manufacturing processes to ensure timely delivery and consistent availability.

Warranty Commitments

We stand behind the quality and durability of our products. The Three-layer Pressure-Relief Mattress comes with a comprehensive warranty:

- Mattress Core: 8-year limited warranty against manufacturing defects and loss of pressure redistribution capabilities beyond acceptable industry standards.

- Mattress Cover: 2-year limited warranty against material defects and failures in fluid-proof integrity under normal use and cleaning protocols.

Full warranty terms and conditions are provided with each purchase.

Dedicated Customer Support

Our commitment to our clients extends beyond the sale. We offer dedicated customer support to ensure seamless integration and optimal performance of our products:

- Technical Support: Access to product specialists for queries regarding specifications, usage, and maintenance.

- Installation and Training: Guidance on initial setup and training for clinical and maintenance staff on best practices for care and handling.

- After-Sales Service: Responsive support for warranty claims, parts replacement, and troubleshooting.

Contact our support team at support@xinmattress.com or call us at +1-800-XXX-XXXX for any assistance.

Conclusion

The Three-layer Pressure-Relief Mattress represents the pinnacle of modern medical mattress technology, meticulously designed to meet the rigorous demands of contemporary healthcare. By integrating advanced materials, precision manufacturing, and adherence to stringent quality standards, this pressure distribution mattress delivers unparalleled pressure redistribution, microclimate management, and infection control capabilities. For healthcare institutions committed to elevating patient care standards while optimizing operational efficiency and ensuring long-term value, investing in a superior pressure sore prevention mattress is not merely a choice but a strategic imperative. We are dedicated to providing solutions that foster healing, enhance comfort, and contribute significantly to a safer, more effective healthcare environment.

References

- National Pressure Injury Advisory Panel (NPIAP). Prevention and Treatment of Pressure Ulcers/Injuries: Clinical Practice Guideline. 2019.

- European Pressure Ulcer Advisory Panel (EPUAP) & Pan Pacific Pressure Injury Alliance (PPPIA). International Clinical Practice Guideline for the Prevention and Treatment of Pressure Injuries. 2019.

- Defloor, T., et al. "Do pressure relief mattresses reduce the risk of pressure ulcers?" A meta-analysis. Journal of Wound, Ostomy and Continence Nursing, 2005.

- Kelsey, R. E. "An overview of support surfaces for pressure ulcer prevention and treatment." Wound Management & Prevention, 2014.

- Ohura, T. "The effects of bed characteristics on prevention of pressure ulcers and patient comfort." Journal of Medical Engineering & Technology, 2016.

-

The Truth About "Orthopedic" Mattresses for Sore Back PainNewsAug.23,2025

-

Space-saving Benefits of a Single Mattress CubeNewsAug.23,2025

-

Eco-friendly Advantages of a Silicon MattressNewsAug.23,2025

-

How to Fix Sagging in a Special MattressNewsAug.23,2025

-

How Ambulance Stretcher Mattresses Reduce Pressure InjuriesNewsAug.23,2025

-

Best Cleaning Practices for a Hospital Mattress DoubleNewsAug.22,2025

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025