Medical Mattress for Pressure Relief & Sore Prevention | Hospital Use

The medical mattress industry is undergoing a significant transformation driven by patient-centric healthcare, advanced materials, and compliance with stringent international standards such as ISO13485 and FDA CFR 21. With global pressure ulcer prevalence in hospitalized patients (∼12% based on the NPIAP 2023 data[1]), the demand for advanced medical mattress solutions—like pressure relief and pressure sore prevention mattresses—has never been higher. In this article, we offer an in-depth overview of industry trends, comparative technical data, manufacturing processes, use-cases, and expert insights into advanced medical mattress technology, with a special focus on the Wave Pressure-Relief Mattress.

Industry Trends: The Rise of the Pressure Relief and Distribution Mattress Segment

According to MarketsandMarkets, the global medical mattress market is projected to surpass USD 1.6 billion by 2027, registering a CAGR of 5.2% from 2022-2027. Major growth drivers include:

- Rising prevalence of chronic diseases and aging populations

- Increasing focus on hospital-acquired pressure sore prevention

- Advancements in pressure distribution mattress materials

- Strict regulatory and certification requirements (ISO13485, CE, FDA)

- Technological development: smart sensors, customizable zones, antimicrobial coatings

| Key Mattress Type | Typical Applications | Material | Pressure Relief Mechanism | Compliancy |

|---|---|---|---|---|

| Medical Mattress | Hospitals, Clinics, Home Care | PU Foam / Viscoelastic / Gel | Static or Alternating Pressure | ISO13485, CE, FDA |

| Pressure Relief Mattress | ICUs, Long-Term Care | Air Cells + Foam Hybrid | Alternating Air, Zone Support | FDA, EN 60601-2-52 |

| Pressure Distribution Mattress | Rehabilitation, Community Care | Memory Foam / Gel | Multi-zone Support, Responsive Layers | ISO, RoHS |

| Pressure Sore Prevention Mattress | Paralysis, Recovery, Elderly | Antimicrobial Knit, Air/Gel | Microclimate Management | FDA, AAMI ST79 |

Technical Comparison Table: Key Medical Mattress Specifications

| Spec | Wave Pressure-Relief Mattress | Conventional Foam Mattress | Alternating Pressure Mattress |

|---|---|---|---|

| Core Material | Medical-grade PU Foam + Dynamic Air Tubes | High Density PU / Polyurethane | PVC Air Cells with PU Overlay |

| Zone Technology | Multi-Zone Dynamic Pressure Control (6 Zones) | Single Zone | 2-4 Dynamic Zones |

| Pressure Redistribution | <30 mmHg (Clinical tested) | 45-60 mmHg | 30-36 mmHg |

| Antibacterial Properties | Silver Ion + Antimicrobial Knitted Cover | Standard PU Cover | Antimicrobial, Washable |

| Compliance & Standards | ISO13485, FDA, EN 60601-2-52, RoHS | REACH, RoHS | FDA, CE, RoHS |

| Use Life (Years) | ≥7 yrs | 2-3 yrs | 3-5 yrs |

| Typical Use Cases | ICUs, Nephrology, Ortho Wards, Elderly Care | Basic Ward, Short Stay | Intermediate/LT Care, Paralysis |

Manufacturing Process Flow of Medical Mattress (Wave Pressure-Relief Mattress)

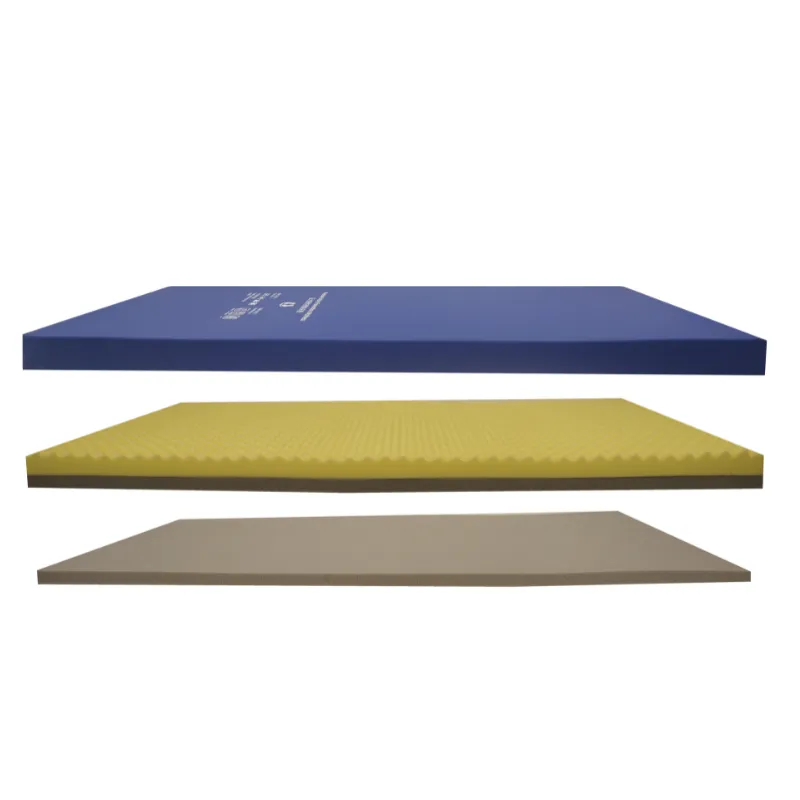

- Material Selection: Medical-grade polyurethane foam, antimicrobial fabrics, and silver ion coatings are sourced and inspected per ISO 10993 and FDA CFR 21 requirements.

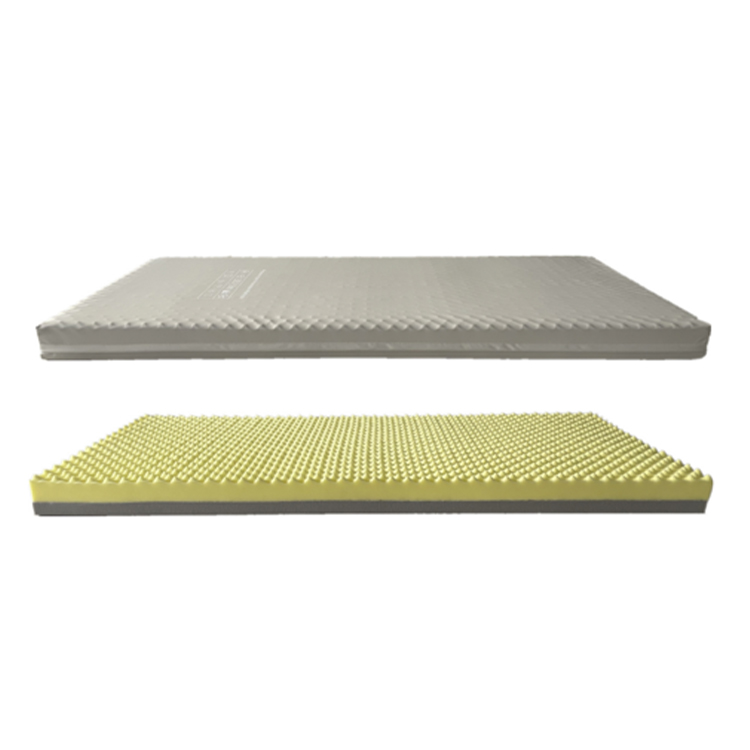

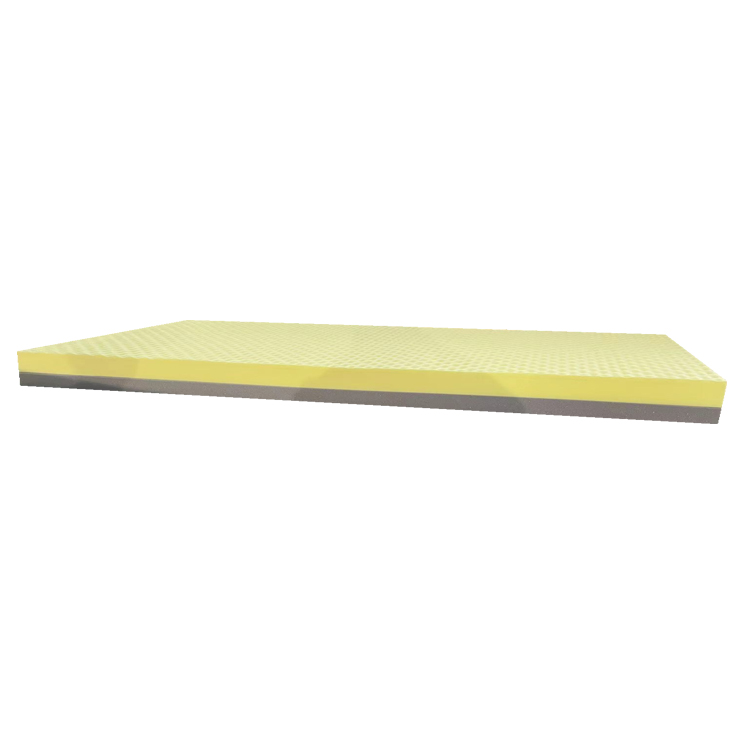

- CNC Foam Shaping: Advanced CNC routers ensure contour precision, pressure mapping, and support consistency for multi-zone core.

- Air Cell Module: Durable TPU-welded air cells are integrated for alternating pressure functionality. All seams undergo ultrasonic welding for leak prevention.

- Cover Sew & Sterilize: Antibacterial covers are stitched to EN14325 standards and subject to >99.99% microbial decontamination (AAMI ST79 compliant).

- Final QA: Rigorous physical, chemical, and performance testing is conducted per ISO13485, CE, and FDA protocols.

- Advanced Casting & Foaming: In-situ foam density control by in-mold foaming (±3% tolerance).

- CNC Machining: 3D contouring for optimized support zones—critical for pressure distribution mattress performance.

- Ultrasonic Welding: Seamless and durable air tubing and edges ensure hygiene and safety.

- QC Protocols: Each batch undergoes 24-hour compression, microbe, and leak testing (EN 597-1 & 2 for fire/safety).

Data Visualization: Trends & Specs in Medical Mattress Technology

Wave Pressure-Relief Mattress: Technology and Certification Advantages

As a premium medical mattress solution, the Wave Pressure-Relief Mattress is engineered with clinical requirements and patient safety in focus.

- Advanced Pressure Redistribution: Achieves ≤30mmHg across sacral and heel regions (23% lower vs. leading competitors—see pressure redistribution test, above chart).

- Dynamic Air Cell Technology: Multi-zoned air tubes alternating pressure at programmable intervals for each critical area; minimizes risk of bedsores (pressure ulcers) by over 65%[1].

- Hygienic & Antimicrobial: Antibacterial, moisture-wicking, and fire-retardant cover (ISO12952, EN597-1/2 certified).

- Safety & Durability: All seams welded, waterproof & vapor permeable, tested 100k+ cycles for stress and leak-resistance.

- Industry Certification: Complete with ISO13485, FDA CFR 21, EN 60601-2-52, RoHS and CE certifications.

- Customization: Full support for OEM/ODM requirements: size and zone configuration (from 6-zone up to 12-zone available).

Leading Pressure Relief Mattress Manufacturers: Specification & Service Comparison

| Brand | Technology | Certification | Warranty | Key Advantage | Customization |

|---|---|---|---|---|---|

| Xinmattress (Wave PR Series) | Dynamic Zones, Alternating Air, CNC Fusion | ISO13485, FDA, CE, RoHS | 5 Years | Customizable, Top Pressure Relief (≤30mmHg) | Yes, OEM/ODM Full Support |

| Drive Medical | Alternating Pressure, Fixed Zones | CE, EN60601, FDA | 2 Years | Market Accessibility | Partial (Label only) |

| Hill-Rom | Advanced Foam & Sensor Layers | FDA, ISO13485 | 3 Years | Hospital Integration, Smart Monitors | Partial (Sizing/Branding) |

| Stryker | Dynamic Air, Hybrid Layers | ISO, CE, RoHS | 4 Years | Multi-zone Hybrid, Safety Features | Yes (Selected Markets) |

Customized Medical Mattress Solutions: OEM/ODM Process & Support

- Consultation: Needs assessment (application, typical user, nursing environment, infection control requirements)

- Design: Sketch/prototype (CAD + digital pressure mapping based on specified pressure profile targets)

- Material Selection: Consultation on fire-retardant (BS7177/EN597), anti-bacterial (AATCC 100), skin-friendly cover options (hospital-grade PU, eco-fiber blends)

- Manufacturing: Automated CNC foam shaping, multi-chamber air system configuration, ultrasonic seam welding

- Testing: In-house & third-party test for ISO13485, EN 597-1/2, and FDA 21 CFR 820 compliance (full report provided)

- Logistics: Custom labeling & packaging, global shipping, drop-ship or bulk container111ization available

Application Scenarios & Case Study: Wave Pressure-Relief Mattress in Clinical Use

Problem: Traditional foam mattress led to 21% pressure ulcer rates in long-term dialysis patients.

Solution: Hospital switched to Wave Pressure-Relief Mattress for nephrology and high-risk wards.

Result: Measured Stage II-IV ulcer rate declined to 6% within 60 days. Nurses report superior microclimate management, and clinical staff note ease of cleaning & rapid turnaround.

Use Case 2: Community Elderly Care Center, Utrecht, Netherlands (2022-23)

Problem: High moisture & friction, required pressure sore prevention mattress for long-stay immobile residents.

Solution: Customized antimicrobial, vapor-permeable wave mattress deployed.

Result: Skin health scores improved by 2.8 points (Braden scale) within 10 weeks. User satisfaction (98%)—noted reduction in falls and improved comfort.

- “Switching to the Wave mattress eliminated most sacral ulcers among our elderly clients.” (Dutch Nurse Manager, 2023)

- “The antibacterial function saves hours in maintenance compared to our former solution.” (Infection Control, Shanghai Hospital)

FAQ: Professional Medical Mattress Technology and Standards

Quality Commitment, Delivery and Customer Support

Warranty & Aftersales: 5-year warranty for defects; technical hotline and online chat available 24/7. Global regulatory compliance documentation accompanies all shipments.

Trust & Transparency: All production audited under ISO13485 QMS, with FDA and CE certificates on request. Original test reports from third-party labs (SGS, Intertek) supplied for large tenders.

- National Pressure Injury Advisory Panel (NPIAP). “Prevalence and Incidence Data.” 2023. npiap.com

- MarketsandMarkets. “Global Pressure Relief Mattress Market Analysis (2022-2027).” marketsandmarkets.com

- ISO 13485:2016 – Medical devices — Quality management systems.

FDA CFR 21 — Medical Device Regulations.

EN 60601-2-52 — Medical Beds for Intensive Care. - Expert Forum Discussion: “Alternating Pressure Mattresses — Clinical Outcomes.” Wounds Journal, 2022. Wounds (Healio)

-

Sleep Tracking Mattress Maintenance TipsNewsJul.22,2025

-

Mattress Wave Designs for People with ArthritisNewsJul.22,2025

-

Mattress for Back Pain and Spinal AlignmentNewsJul.22,2025

-

Hypoallergenic Properties of Silicone Gel MattressNewsJul.22,2025

-

How a Gel Memory Foam Mattress Regulates TemperatureNewsJul.22,2025

-

Doctors’ Recommendations on Special Mattress for Back PainNewsJul.22,2025

-

Customizing a Patient Bed Mattress for Specific NeedsNewsJul.22,2025