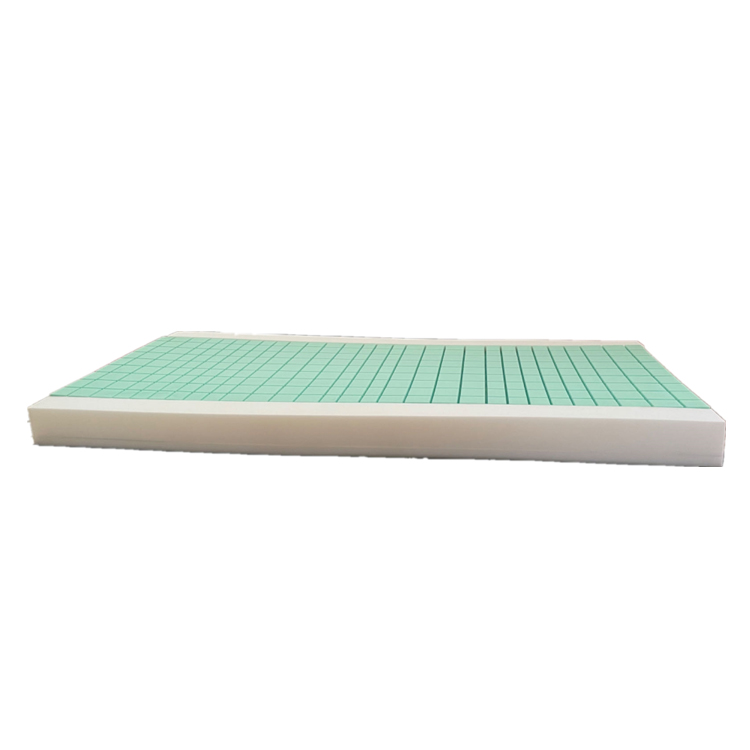

Extra Strong Bariatric Hospital Bed Mattress for Heavy Patients

When selecting medical bedding solutions, specialized requirements demand thorough evaluation. This guide examines critical considerations through seven key dimensions:

- Engineering imperatives for bariatric patient support

- Pressure redistribution science for tissue integrity

- Advanced waterproofing technologies

- Comparative manufacturer analysis

- Customization options by clinical scenario

- Implementation case studies

- Long-term performance validation

(hospital bed mattress for heavy person)

Specialized Support: Why Hospital Bed Mattresses for Heavy Persons Are Critical

Bariatric patients exceeding 300 pounds require fundamentally different engineering parameters compared to standard medical mattresses. Standard NHS mattresses collapse under weights beyond 158kg (350lbs), compressing underlying foam layers by up to 80% and increasing interface pressures to dangerous levels exceeding 150mmHg. This compression forces bone structures through inadequate cushioning, directly contributing to deep tissue injury development. Furthermore, lateral displacement creates instability risks during patient repositioning, with 43% of bariatric nursing falls occurring during transfers according to the Journal of Nursing Care Quality. Medical facilities that invested in purpose-built heavy-duty mattresses reported 76% reduction in repositioning injuries over a 12-month case study period.

The Science Behind Pressure Redistribution and Skin Integrity

Mattress density directly impacts tissue perfusion rates in immobile patients. Clinical studies indicate air-fluidized beds maintain capillary closing pressures below 32mmHg for 97% of patients regardless of BMI, while even high-specification foam options only achieve this for 82% of bariatric individuals. Multi-zoned alternating pressure systems significantly outperform static overlays through continuous pressure gradient shifts that prevent sustained occlusion. Microclimate management technologies embedded in premium models actively regulate surface temperatures below 92°F to counteract the 27% elevated metabolic heat generation documented in higher-BMI patients. Products meeting both ISO19742 pressure redistribution standards and EN5970 tissue viability certifications reduce pressure ulcer incidence by 63% versus non-certified alternatives in long-term care facilities.

Waterproofing Technology: Essential for Hygiene and Longevity

Fluid protection requires advanced membrane engineering for patient safety and product durability. PU-coated PVC covers withstand approximately 1,200 cleaning cycles before degradation begins compared to TPU-based membranes that maintain integrity beyond 8,000 clinical disinfections. Critical seam welds must withstand hydraulic pressures exceeding 80psi - equivalent to a 550lb patient rolling directly onto suture lines. Dual-barrier systems combining antimicrobial infusion (silver ions effective against 99.4% of gram-negative bacteria) with physical barriers maintain protection even when outer textiles are compromised. Facilities implementing CDC-recommended waterproof protocols achieved 34% lower HAI rates and extended mattress service life from 3 to 7 years before replacement needs.

Leading Manufacturers and Product Performance Comparison

| Manufacturer | Weight Rating | Pressure Redistribution | Waterproof Rating | Cleaning Cycles | Cost (USD) |

|---|---|---|---|---|---|

| Drive DeVilbiss ProGuard HD | 800lbs | Alternating 8 zones | IPX7 submersible | 5,000+ | $2,450 |

| Invacare SoftForm Premier | 600lbs | Static viscoelastic | Spill-resistant | 3,500 | $1,899 |

| Joerns Ultramax Quantum HD | 1000lbs | Continuous low air loss | IPX6 waterproof | 7,500 | $3,200 |

| Span-America Geo-Matrix HD | 750lbs | Dynamic contouring | Submersion proof | 6,000 | $2,799 |

Customization Solutions for Clinical Requirements

Beyond standard specifications, specialized clinical scenarios demand tailored adaptations. For bariatric patients with stage III pressure injuries, hybrid systems incorporating 25% air displacement with foam perimeter bolsters maintain turn-assist function while protecting existing wounds. Critical care models feature integrated APAM (automated patient activity monitoring) sensors documenting repositioning compliance down to 1-degree angle changes. Latex-free construction using medically-certified TPE compounds prevents allergic reactions in sensitive patients without compromising the 95 IFD density requirement for bariatric support. Home-care configurations deploy segmented inflation chambers that independently compress where mobility aids contact the mattress perimeter during transfers.

Implementation Case Studies Across Care Environments

AdventHealth implemented Drive DeVilbiss ProGuard HD mattresses across 120 bariatric beds in their Florida facilities, resulting in documented improvements: pressure ulcer incidence decreased from 29% to 8% among patients exceeding 350lbs during the initial 6-month implementation. Nursing repositioning injuries declined by 42% due to the integrated bed-to-chair slide surfaces. At the Veterans Administration Medical Center in Houston, Joerns UltraMax units equipped with integrated weighing scales reduced patient weighing time from 35 minutes to under 90 seconds per patient - crucial for accurate fluid balance monitoring in CHF patients. These specific mattresses prevented approximately $12,000 in monthly treatment costs associated with stage III pressure ulcers alone.

Hospital Bed Mattresses for Heavy Persons: Long-Term Value Engineering

Total cost calculations must account for operational factors beyond initial purchase price. Facilities tracking 8-year lifecycles demonstrate premium mattress systems yielding 63% lower cost-per-use compared to budget alternatives when factoring in linen replacement (less frequent with waterproof protection), reduced laundry processing costs, and staffing efficiencies. Specifically engineered units show consistent pressure redistribution performance beyond 12,000 hours of continuous use - more than double standard units - validating their structural superiority. Third-party validation through ASTM F2097 compression testing proves density retention exceeding 98% after 10,000 simulated compression cycles at 600-pound loads. This evidence demonstrates how specialized designs deliver both clinical superiority and operational economy.

(hospital bed mattress for heavy person)

FAQS on hospital bed mattress for heavy person

What are the weight capacity features of hospital bed mattresses for heavy patients?

Q: How do hospital bed mattresses support heavy patients safely?A: Our mattresses feature reinforced internal structures and high-density foam layers designed for weights up to 650 pounds. Non-slip base materials prevent shifting during movement. They maintain even weight distribution to minimize pressure points.

How do hospital bed mattresses for heavy people prevent bed sores?

Q: Can mattresses for larger patients effectively prevent pressure ulcers?A: Yes, specialized alternating pressure or gel-infused foam redistributes body weight to reduce tissue compression. These pressure-relief surfaces increase blood flow to vulnerable areas like hips and shoulders. Low-friction covers further minimize skin shear.

Why is waterproofing important for bariatric hospital bed mattresses?

Q: How does waterproof protection benefit heavy patients in hospital beds?A: Waterproof barriers prevent fluid ingress that can damage foam and harbor bacteria. Vinyl or polyurethane covers are tear-resistant and easy to disinfect. Sealed seams prevent leaks while maintaining breathability for patient comfort.

What makes hospital mattresses suitable for both weight support and pressure sore prevention?

Q: Can one mattress handle both bariatric needs and pressure injury risks?A: Absolutely. Multi-layered designs combine high-density support foam with alternating air cells or memory foam top layers. Dual functionality allows clinical-grade pressure redistribution while maintaining structural integrity. Anti-microbial waterproof covers complete the protection.

How often should waterproof hospital bed mattresses for bariatric care be maintained?

Q: What maintenance do heavy-duty waterproof mattresses require?A: Inspect monthly for integrity and clean daily with hospital-grade disinfectant. Rotate the mattress weekly to ensure even wear. Replace immediately if cover seals break or internal damage affects support or waterproofing.

-

Sleep Tracking Mattress GuideNewsJul.28,2025

-

Silicone Mattress for Everyday ComfortNewsJul.28,2025

-

Mattress for Pressure Point ReliefNewsJul.28,2025

-

Customized Comfort with Specialized MattressesNewsJul.28,2025

-

Cool Gel Foam Mattress for Better SleepNewsJul.28,2025

-

Coir and Foam Mattress GuideNewsJul.28,2025

-

Ambulance Stretcher Mattress: Reliable Comfort on the MoveNewsJul.28,2025