Exploring the Benefits of Solo Mattress Manufacturing for Quality Sleep Solutions

The Emergence and Impact of Solo Mattress Factories

In recent years, the bedding industry has witnessed a significant transformation, particularly with the rise of solo mattress factories. This trend represents a departure from traditional manufacturing models, showcasing the advantages of smaller, specialized production facilities that focus on quality, customization, and sustainability. In this article, we delve into the essence of solo mattress factories, exploring their operations, benefits, and the way they are shaping the future of mattress production.

What Are Solo Mattress Factories?

Solo mattress factories refer to independent manufacturing units that focus specifically on creating mattresses in smaller batches. Unlike large-scale manufacturers that produce thousands of mattresses in a single run, solo factories emphasize the craftsmanship involved in mattress making, often tailoring their products to meet specific customer needs. These factories may operate on a made-to-order basis, allowing for customization in materials and design that is often unavailable from mass producers.

Craftsmanship and Customization

One of the major advantages of solo mattress factories is their emphasis on craftsmanship. Skilled artisans and technicians are often employed to ensure that each mattress is constructed with care and attention to detail. This allows for a level of quality assurance that is hard to achieve in larger factories where speed and volume often take precedence over individual craftsmanship.

Furthermore, the ability to customize mattresses has opened new avenues for consumer choice. Customers today are increasingly looking for products that cater to their specific preferences regarding firmness, materials, and design. Solo mattress factories can respond effectively to these demands, offering bespoke solutions that enhance customer satisfaction and bolster brand loyalty.

Sustainability and Eco-Friendly Practices

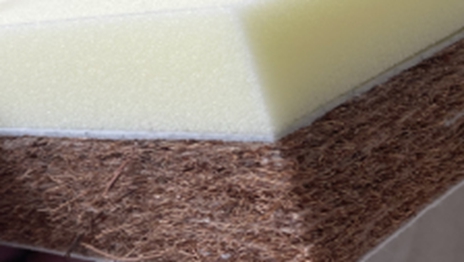

In addition to craftsmanship, many solo mattress factories prioritize sustainability in their operations. They tend to utilize eco-friendly materials such as organic cotton, natural latex, and non-toxic foam. This focus on sustainable practices attracts a growing number of environmentally-conscious consumers who prefer products that are gentle on the planet.

solo mattress factories

Moreover, smaller production runs mean reduced waste and a lower carbon footprint compared to traditional manufacturing methods. Many solo factories embrace local sourcing and production, which not only supports local economies but also minimizes transportation emissions. By prioritizing sustainable practices, solo mattress factories can align their operations with the values of a more environmentally aware consumer base.

The Digital Era and Direct-to-Consumer Model

The advent of the digital age has also enabled solo mattress factories to thrive. With direct-to-consumer (DTC) models gaining traction, these factories can reach their customers through online platforms without relying heavily on brick-and-mortar retail stores. This strategic shift reduces costs, making high-quality mattresses more accessible to a broader audience.

Through effective use of social media and digital marketing, solo mattress factories can engage with their customers, garner feedback, and build a community around their brand. This direct interaction not only fosters customer loyalty but also allows manufacturers to adapt quickly to changing market demands and preferences.

The Future of Mattress Production

As the bedding industry continues to evolve, the role of solo mattress factories is likely to expand. They represent a shift towards more mindful consumerism—an approach that favors quality, customization, and sustainability over mass production.

As consumers become more health-conscious and discerning about the materials they choose for their homes, solo mattress factories are well-positioned to meet these needs. By offering a range of high-quality, customizable options that align with sustainable practices, these factories can capture a growing market segment that prioritizes wellness and environmental responsibility.

Conclusion

Solo mattress factories are redefining the landscape of mattress production through their commitment to craftsmanship, customization, and sustainability. By leveraging the power of direct-to-consumer sales in the digital age, these factories provide an appealing alternative to traditional manufacturing methods. As we look to the future, the innovations and practices embraced by solo mattress factories may well set the standard in the bedding industry, ensuring that consumers can sleep soundly on products made with care for both their health and the environment.

-

the-truth-about-orthopedic-mattresses-for-sore-back-painNewsAug.23,2025

-

space-saving-benefits-of-a-single-mattress-cubeNewsAug.23,2025

-

eco-friendly-advantages-of-a-silicon-mattressNewsAug.23,2025

-

how-to-fix-sagging-in-a-special-mattressNewsAug.23,2025

-

how-ambulance-stretcher-mattresses-reduce-pressure-injuriesNewsAug.23,2025

-

best-cleaning-practices-for-a-hospital-mattress-doubleNewsAug.22,2025

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025