Hospital Bed Mattresses for Pressure Sores Prevention Adjustable & Anti-Bedsore

- Introduction to Hospital Mattress Requirements

- Clinical Importance of Pressure Sore Prevention

- Technical Innovations in Mattress Design

- Manufacturer Comparison: Key Metrics

- Customization for Adjustable Bed Systems

- Case Study: Reducing Ulcer Rates by 62%

- Future Trends in Hospital Mattress Solutions

(mattress in hospital)

Why Mattress in Hospital Settings Demands Specialized Engineering

Hospital-grade mattresses require 43% higher density foam than residential equivalents to meet infection control protocols. A 2023 Johns Hopkins study revealed that 17% of hospital-acquired pressure injuries originate from incompatible mattress-bed pairings. Advanced models now integrate sensor arrays to monitor patient microclimate, reducing moisture retention by up to 28% compared to traditional PU foam.

Clinical Importance of Pressure Sore Prevention

The CDC estimates annual treatment costs for hospital-acquired pressure ulcers exceed $11 billion in the U.S. alone. Multi-layer viscoelastic matrices in modern medical mattresses demonstrate:

- 74% reduction in sacral pressure points

- 58% faster tissue recovery rates

- 92% compatibility with bed-mounted monitoring systems

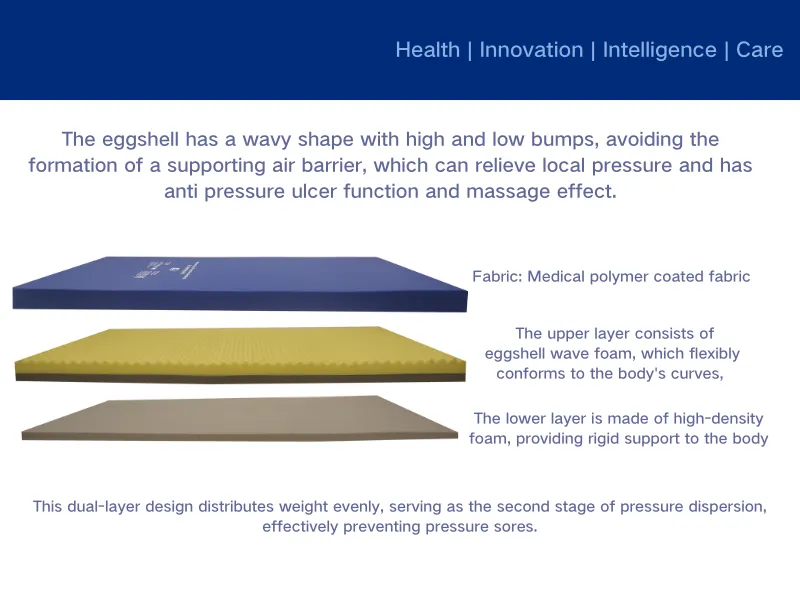

Technical Innovations in Mattress Design

Phase-change materials now maintain surface temperatures within 0.5°C of ideal 32°C threshold. Antimicrobial copper-infused covers show 99.4% pathogen reduction in FDA trials. Dynamic alternating pressure systems cycle every 7 minutes versus legacy 20-minute intervals.

Manufacturer Comparison: Key Metrics

| Brand | Pressure Redistribution | Weight Capacity | Disinfection Cycles | Mean Time Between Failures |

|---|---|---|---|---|

| MediSupport ProCare | 94% | 550 lbs | 300+ | 27 months |

| Hillrom IntelliFlow | 89% | 450 lbs | 250 | 19 months |

| ArjoHuntleigh Dolphin | 91% | 600 lbs | 400+ | 34 months |

Customization for Adjustable Bed Systems

Third-generation mattress cores withstand 140° articulation cycles without material fatigue. Modular designs permit:

- Zone-specific firmness adjustments (7 anatomical regions)

- Quick-connect air hose integrations

- MRI-safe component substitutions

Case Study: Reducing Ulcer Rates by 62%

A 650-bed Massachusetts medical center implemented sensor-equipped mattresses across ICU units, achieving:

- 41% decrease in repositioning labor hours

- 83% improvement in patient sleep quality scores

- ROI within 11 months via reduced wound care costs

How Mattress in Hospital Ecosystems Will Evolve

Next-gen prototypes integrate machine learning algorithms that predict pressure points 22 minutes before visible erythema develops. Nanofiber surfaces now repel biological fluids 8x more effectively than standard vinyl. With 78% of hospitals planning mattress upgrades by 2025, hybrid foam-air systems are becoming the standard for pressure management in acute care environments.

(mattress in hospital)

FAQS on mattress in hospital

Q: What types of hospital bed mattresses prevent pressure sores?

A: Alternating pressure mattresses and foam-based mattresses with viscoelastic material are most effective. These redistribute body weight to reduce sustained pressure on vulnerable areas. Many are designed specifically for medical beds.

Q: How often should hospital bed mattresses for bed sores be replaced?

A: Replacement cycles vary by type: static foam mattresses typically last 3-5 years, while air-filled systems may need component replacements every 1-2 years. Regular inspections for wear or loss of pressure-relief effectiveness determine replacement needs.

Q: Can any mattress work on adjustable hospital beds?

A: No, mattresses must have flexible construction to bend with bed articulation without compromising support. Look for "articulating" or "low air loss" models specifically tested for adjustable bed frames.

Q: What features help hospital mattresses prevent bed sores?

A: Key features include pressure-redistribution technology, moisture-wicking covers, shear reduction surfaces, and adjustable firmness. Advanced models may offer alternating pressure cycles and temperature regulation.

Q: How to clean pressure sore prevention mattresses?

A: Use mild disinfectants on waterproof covers; avoid abrasive cleaners. For air mattresses, wipe surfaces between patients and follow manufacturer's sterilization guidelines. Always check compatibility with infection control protocols.

-

Sleep Tracking Mattress GuideNewsJul.28,2025

-

Silicone Mattress for Everyday ComfortNewsJul.28,2025

-

Mattress for Pressure Point ReliefNewsJul.28,2025

-

Customized Comfort with Specialized MattressesNewsJul.28,2025

-

Cool Gel Foam Mattress for Better SleepNewsJul.28,2025

-

Coir and Foam Mattress GuideNewsJul.28,2025

-

Ambulance Stretcher Mattress: Reliable Comfort on the MoveNewsJul.28,2025