Waterproof Medical Mattresses | Home & Hospital Care | Best Grade

Advancements in Medical Mattress Technology for Enhanced Patient Care

In the evolving landscape of healthcare, the role of specialized equipment in patient recovery and comfort cannot be overstated. Among these, medical mattress technology stands at the forefront, revolutionizing standards of `medical care`. These sophisticated bedding solutions are specifically engineered to address the unique challenges faced in clinical and home care settings, extending far beyond the capabilities of conventional mattresses. They are instrumental in preventing pressure injuries, ensuring optimal hygiene, and providing therapeutic support. The growing demand for advanced solutions, driven by an aging global population and an increased focus on preventative health, underscores the critical importance of selecting the right mattress. This article delves into the technical aspects, industry trends, and practical benefits of modern medical mattress products, offering insights for B2B decision-makers.

The design philosophy behind a medical mattress is rooted in biomechanics and material science, aiming to minimize pressure points and facilitate even weight distribution. This is crucial for bedridden patients or individuals with limited mobility, as prolonged pressure on specific body areas can lead to severe skin breakdown and pressure ulcers, also known as decubitus ulcers. Furthermore, the advancements in materials and manufacturing processes have led to the development of mattresses that are not only comfortable but also highly durable, easy to clean, and resistant to contaminants, making them an indispensable component of modern healthcare infrastructure, from hospitals and clinics to `home medical mattress` applications. Their specialized construction is key to providing comprehensive `medical care`.

The Anatomy of a High-Performance Medical Mattress: Materials and Manufacturing Excellence

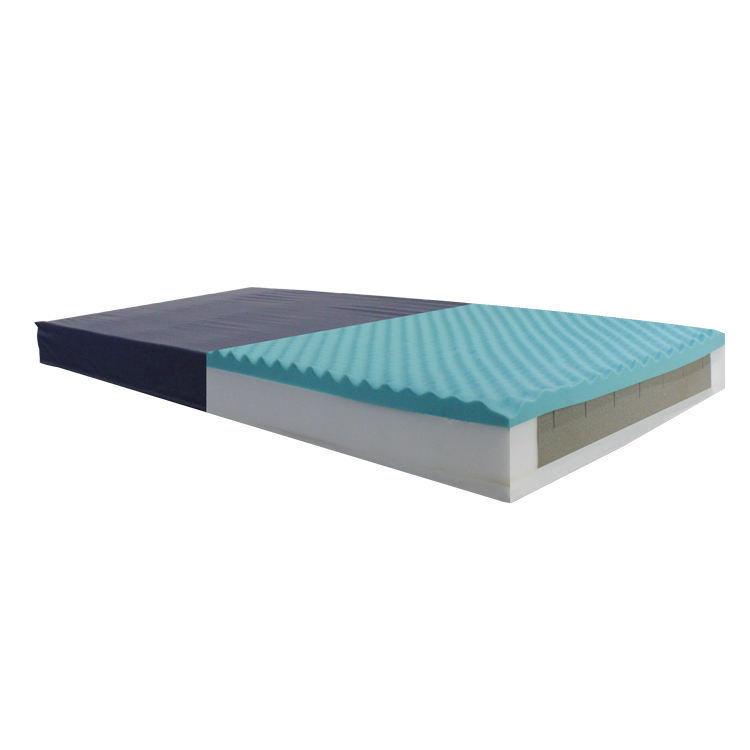

The superior performance of a medical mattress is a direct result of meticulously selected materials and advanced manufacturing techniques. Understanding these elements is key to appreciating their value in `medical care`. Core materials often include high-density polyurethane foams, viscoelastic foams (memory foam), or advanced air cell systems. Polyurethane foams offer excellent support and durability, while viscoelastic foams conform to the body's contours, providing superior pressure redistribution and comfort. For patients requiring dynamic pressure relief, alternating air pressure systems utilize a series of interconnected air cells that inflate and deflate cyclically, shifting pressure points and promoting blood circulation, thereby preventing tissue ischemia.

Crucially, the external cover of a medical mattress is typically made from specialized materials such as polyurethane (PU) coated fabrics or vinyl. These materials are chosen for their fluid impermeability, breathability, and ease of cleaning, which are vital for infection control and maintaining a hygienic patient environment. Many covers are also anti-microbial, inhibiting the growth of bacteria and fungi, and fire-retardant, adhering to stringent safety standards like CAL 117. The combination of these advanced materials ensures that the mattress can withstand the demanding conditions of medical facilities while providing optimal therapeutic benefits.

Manufacturing Process: Precision and Quality Assurance

The production of a medical mattress involves a sophisticated multi-stage process designed to ensure structural integrity, functional performance, and compliance with rigorous healthcare standards. This robust process ensures every `medical grade mattress` meets the highest industry benchmarks.

- Material Sourcing and Preparation: High-grade foams (e.g., CertiPUR-US certified) and technical fabrics are carefully selected. Foams undergo cutting and shaping using precision CNC machinery to form the core layers according to specific design parameters, such as varying densities for zoned support and patient weight distribution.

- Layering and Bonding: Different foam layers (e.g., a firm base for stability, a softer comfort layer, or a specialized convoluted pressure-redistributing top layer) are accurately bonded together using medical-grade, solvent-free adhesives or advanced thermal laminating techniques. This ensures the integrity of the mattress core and prevents layer shifting, maintaining consistent therapeutic properties.

- Cover Fabrication and Sealing: The `waterproof mattress` covers, typically made from PU-coated nylon or vinyl, are cut and then precision-stitched or radio-frequency (RF) welded. RF welding is particularly effective for creating hermetically sealed seams, preventing fluid ingress and enhancing hygiene, making it a truly `famous waterproof mattress` in terms of its protective capabilities against contaminants and fluids.

- Assembly and Integration: The prepared mattress core is inserted into the cover, which often features a full-length zipper for easy removal and cleaning. For alternating air pressure mattresses, intricate air bladders, quiet pumps, and intelligent control systems are meticulously integrated and tested to ensure all components function seamlessly for dynamic pressure management.

- Rigorous Quality Control: Every medical mattress undergoes extensive testing protocols. This includes pressure mapping to verify effective pressure redistribution, fluid immersion tests for waterproofing (e.g., hydrostatic head test), durability testing for lifespan projection (e.g., indentation force deflection tests), and flame retardancy compliance. Adherence to international standards like ISO 13485 (Medical Devices Quality Management) and FDA regulations is paramount for a `medical grade mattress`, ensuring maximum safety and efficacy.

- Packaging: Finished mattresses are compressed (if applicable) and securely packaged for transport, often in vacuum-sealed bags to maintain hygiene, minimize shipping volume, and reduce environmental footprint.

Precision cutting and assembly are critical steps in producing a high-quality medical mattress.

Key Technical Parameters and Performance Metrics

When evaluating a medical mattress, understanding its technical specifications is paramount for procurement specialists and healthcare providers. These parameters dictate the mattress's suitability for various patient needs and clinical environments. A truly `best medical mattress` distinguishes itself through superior performance across these metrics, offering long-term value and enhanced patient outcomes, directly contributing to superior `medical care`.

Medical Mattress Technical Specifications Overview

| Parameter | Description | Typical Range / Value |

|---|---|---|

| Core Material | High-density polyurethane foam, viscoelastic (memory) foam, air cells, gel. | Variable based on pressure ulcer risk level (low, medium, high); Density: 1.8-2.5 lbs/ft³. |

| Cover Material | Fluid-resistant, breathable, anti-microbial fabric (e.g., PU-coated Nylon/Vinyl). | Fluid impermeability (Hydrostatic Head): >20,000 mm H₂O; MVTR: 500-1500 g/m²/24hrs. |

| Weight Capacity | Maximum patient weight the mattress can support effectively without bottoming out. | Standard: 150-250 kg (330-550 lbs); Bariatric: up to 450 kg (1000 lbs). |

| Pressure Redistribution | Ability to distribute patient weight evenly, reducing peak pressure points (interface pressure). | Low to Very High Risk category specific. Aims for lower interface pressures ( |

| Fire Retardancy | Compliance with relevant national and international fire safety standards. | California Technical Bulletin 117 (CAL 117-2013), BS 7177 (UK), NFPA 260. |

| Certifications | Regulatory and quality assurances indicating adherence to medical device standards. | ISO 13485, FDA Class I/II (USA), CE Marking (EU), CertiPUR-US. |

| Lifespan / Warranty | Expected functional duration and manufacturer's guarantee for components. | Typically 3-7 years for core; Warranty 1-5 years on components. |

These specifications are crucial for ensuring that a medical mattress not only meets regulatory requirements but also delivers optimal therapeutic outcomes and operational efficiency within specific `medical care` environments, including specialized applications like a `waterproof mattress for hospital bed`. The `medical grade mattress` designation signifies that a product has met stringent clinical performance and safety benchmarks, making it suitable for rigorous professional use in high-demand settings.

Application Scenarios and Industry Benefits

The versatility of the medical mattress makes it indispensable across a broad spectrum of healthcare settings. In acute care hospitals, specialized models are critical for managing patients with severe burns, spinal injuries, or those requiring long-term ventilation, where maintaining skin integrity and preventing secondary complications are paramount. For long-term care facilities and nursing homes, durable and easy-to-clean `waterproof mattress` solutions enhance resident comfort and simplify `medical care` protocols, significantly reducing the incidence of pressure ulcers. Furthermore, with the growing trend towards home healthcare, `home medical mattress` options are becoming increasingly sophisticated, allowing patients to receive hospital-level comfort and therapeutic benefits within their own residences, thereby improving their quality of life during recovery or chronic illness management.

Beyond direct patient benefits, the strategic implementation of high-quality medical mattress products offers significant operational advantages to healthcare providers. By actively preventing pressure injuries, hospitals and care facilities can reduce treatment costs associated with wound care, which can be substantial. Statistics show that the average cost to treat a single pressure ulcer can range from $2,000 to over $70,000, depending on its severity. Moreover, improved patient comfort and outcomes can lead to higher patient satisfaction scores and enhanced institutional reputation. The longevity and robust construction of a `medical grade mattress` also translate into reduced replacement costs and maintenance efforts, providing excellent return on investment for healthcare organizations.

A medical mattress seamlessly integrates into various patient care environments, enhancing patient comfort and safety.

Choosing the Right Medical Mattress: Customization and Partnership

Selecting the `best medical mattress` requires a thorough understanding of specific patient needs, environmental constraints, and budgetary considerations. While standard models cater to common requirements, specialized `custom waterproof mattress` solutions are often necessary for unique clinical situations or bariatric patients. Reputable manufacturers, like Xinmattress, offer extensive customization capabilities, allowing healthcare facilities to specify dimensions, foam densities (e.g., higher ILD for bariatric support), cover materials, and integrated features such as side bolsters or transfer aids. This bespoke approach ensures optimal fit and functionality for existing hospital beds or specialized care units, maximizing both patient comfort and staff efficiency in delivering `medical care`.

Partnering with an experienced manufacturer that demonstrates strong `authoritativeness` and `trustworthiness` is crucial. Look for companies with a proven track record of adherence to international quality standards such as ISO 13485 and FDA compliance. Their `expertise` should be evident in their comprehensive product range, robust technical support, and the clarity of their quality assurance processes. Reviews, service case studies highlighting successful implementations, and long-standing client relationships also contribute to a manufacturer's `experience` and reliability. An emphasis on comprehensive after-sales support, including clear warranty terms and efficient delivery schedules for a `waterproof mattress for hospital bed`, further solidifies a manufacturer's commitment to excellence.

Client Testimonials & Service Excellence

"We have relied on Special Supply Medical Mattresses from Xinmattress for years in our critical care units. Their `custom waterproof mattress` solutions have drastically reduced pressure ulcer rates among our vulnerable patient population, and their commitment to `medical care` quality and timely delivery is unparalleled. The exceptional durability of their `waterproof mattress for hospital bed` is also a significant cost-saving factor for our institution, requiring fewer replacements over time."

- Leading Regional Hospital Procurement Manager

Frequently Asked Questions (FAQ)

Q1: What is the average lifespan of a medical mattress?

A1: The lifespan of a medical mattress varies based on its type, usage intensity, and maintenance. High-quality `medical grade mattress` products are designed for durability, typically lasting between 3 to 7 years in demanding clinical settings. Regular cleaning, proper handling according to manufacturer guidelines, and timely inspection can significantly extend its service life and ensure ongoing therapeutic effectiveness.

Q2: How do medical mattresses prevent pressure ulcers?

A2: Medical mattresses prevent pressure ulcers primarily through sophisticated pressure redistribution mechanisms. This is achieved by using specialized foams (e.g., viscoelastic, convoluted designs, zoned support) or dynamic air systems that spread patient weight more evenly across a larger surface area, reducing peak pressure points on vulnerable bony prominences. Features like low shear and friction, along with moisture control from breathable covers, further enhance skin integrity and protection. This makes a `best medical mattress` a key tool in preventative `medical care`.

Q3: Are all medical mattresses waterproof?

A3: While not all medical mattresses are strictly "waterproof" in the sense of full submersion, the vast majority designed for healthcare environments feature `waterproof mattress` covers that are fluid-resistant or fluid-impermeable. These covers utilize advanced materials like polyurethane-coated fabrics to prevent liquids from penetrating the mattress core, which is crucial for hygiene and infection control. Always check the specific product specifications for its precise fluid protection rating.

Q4: What are the typical delivery times for bulk orders of medical mattresses?

A4: Delivery times for bulk orders can vary depending on customization requirements, order volume, and manufacturer's production capacity. Xinmattress, for example, typically aims for a lead time of 4-6 weeks for standard bulk orders, with expedited options available for urgent requirements. Customers are advised to consult directly for precise delivery schedules, especially for `custom waterproof mattress` orders to ensure timely procurement.

Q5: What warranty is offered on Special Supply Medical Mattresses?

A5: Xinmattress provides a comprehensive warranty on its Special Supply Medical Mattresses, demonstrating robust `trustworthiness` in its products. This typically covers manufacturing defects for 3 to 5 years on the mattress core and 1 to 2 years on the outer cover, depending on the specific product model and materials. Full detailed warranty terms and conditions are available upon request to ensure complete client peace of mind and satisfaction.

References

- National Pressure Ulcer Advisory Panel (NPUAP). Prevention and Treatment of Pressure Ulcers: Clinical Practice Guideline. 2014.

- European Pressure Ulcer Advisory Panel (EPUAP). Prevention and Treatment of Pressure Ulcers: Clinical Practice Guideline. 2019.

- International Organization for Standardization (ISO). ISO 13485: Medical devices - Quality management systems - Requirements for regulatory purposes. Current version.

- U.S. Food and Drug Administration (FDA). Medical Devices.

- California Bureau of Electronic and Appliance Repair, Home Furnishings and Thermal Insulation. Technical Bulletin 117-2013: Requirements, Test Procedure and Apparatus for Testing the Smolder Resistance of Materials Used in Upholstered Furniture.

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025

-

Innovative Wave Mattresses for Ultimate ComfortNewsAug.08,2025

-

High-Quality Mattresses for Hospital BedsNewsAug.08,2025

-

High-Quality Mattresses for Every NeedNewsAug.08,2025

-

Healthcare Foam Mattress: Sleep Better, Heal FasterNewsAug.08,2025

-

Cube Mattress for Daily ComfortNewsAug.08,2025

-

How Hospital Mattress Choices Directly Impact Patient Comfort and CareNewsAug.05,2025