Premium Medical Mattresses: Waterproof Comfort & Support

The Evolving Landscape of Medical Mattresses: Trends and Innovations

In the dynamic realm of healthcare, the role of patient support surfaces, particularly the medical mattress, has evolved from a mere comfort accessory to a critical component in comprehensive patient care. Modern medical care demands solutions that not only ensure patient comfort but also actively contribute to positive health outcomes, reduce healthcare-associated complications, and optimize operational efficiencies within medical facilities. The global market for these specialized mattresses is experiencing robust growth, driven by an aging population, increasing prevalence of chronic diseases, and a heightened focus on pressure ulcer prevention and infection control.

Current industry trends point towards significant innovations in materials science, smart technology integration, and sustainable manufacturing practices. Manufacturers are increasingly focusing on developing sophisticated pressure redistribution systems, enhanced fluid resistance, and antimicrobial properties to meet stringent clinical demands. The transition from reactive treatment to proactive prevention of skin integrity issues, such as pressure injuries (previously known as pressure ulcers), is a primary driver. This paradigm shift necessitates mattresses engineered with advanced features that manage microclimates, reduce shear and friction, and evenly distribute pressure across the patient's body. Furthermore, the rising awareness of cross-contamination risks in clinical settings has accelerated the demand for easy-to-clean, disinfectable, and highly durable surfaces, leading to the prevalence of the waterproof mattress design.

The integration of smart technologies, such as embedded sensors for patient monitoring, pressure mapping, and remote adjustability, represents the next frontier. These innovations promise to revolutionize how patients are managed, providing real-time data to clinicians for personalized care interventions and predictive analytics. Simultaneously, there's a growing emphasis on sustainability, with manufacturers exploring eco-friendly materials and production processes to reduce environmental impact. These trends underscore the complex, multidisciplinary approach required in designing and manufacturing a high-quality medical grade mattress that meets the multifaceted needs of contemporary medical environments, from intensive care units to dedicated home medical mattress solutions.

Decoding the Anatomy of a Medical Mattress: Materials and Manufacturing Excellence

The superior performance of a medical mattress is rooted in its meticulously engineered composition and the precision of its manufacturing process. Unlike conventional mattresses, a medical-grade product is designed to meet rigorous clinical specifications, ensuring optimal patient outcomes and durability in demanding healthcare environments. The choice of materials and the adherence to strict manufacturing protocols are paramount.

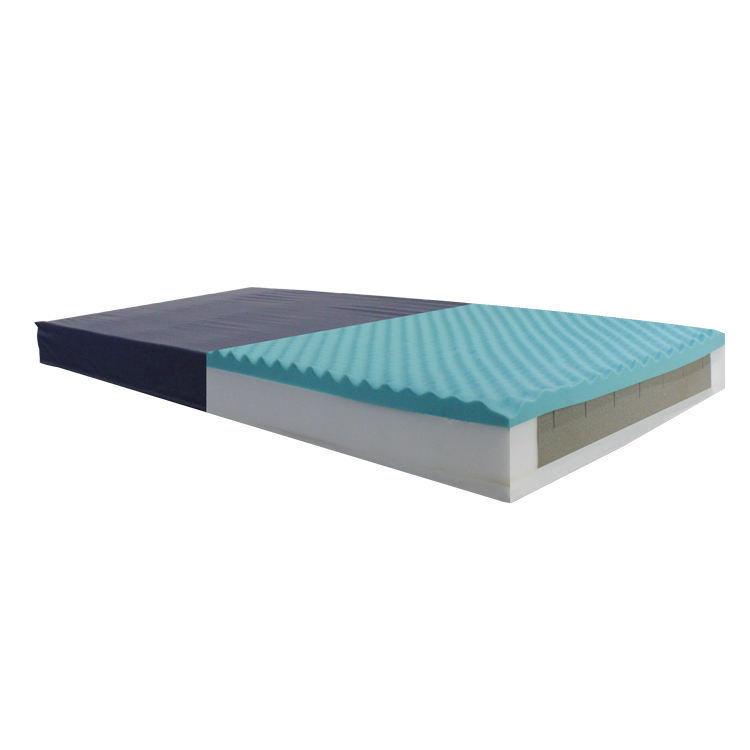

Core Materials and Their Properties:

- High-Density Foams: Often forming the base or support layers, these foams provide foundational stability and prevent bottoming out. Their high resilience ensures long-term structural integrity and uniform support.

- Visco-Elastic Foam (Memory Foam): Renowned for its pressure-redistributing properties, visco-elastic foam contours to the patient's body, minimizing peak pressure points and distributing weight evenly. This significantly reduces the risk of pressure injuries, making it a staple in many best medical mattress designs.

- Multi-Layered Foam Systems: Advanced mattresses often combine layers of different density and composition foams to create zones of varying firmness and pressure relief, tailored to specific body regions and clinical needs.

- Air Cells/Air Bladders: Found in dynamic or alternating pressure mattresses, these systems inflate and deflate in cycles, continuously changing pressure points to stimulate blood flow and provide active pressure relief. They are crucial for patients at high risk of pressure injuries.

- Gel Inserts: Gel pads or layers can be integrated into foam mattresses to enhance cooling, reduce shear, and provide additional pressure redistribution, particularly in high-pressure areas like the sacrum.

- Covers: The outer cover is a critical barrier. Typically made from specialized polyurethane (PU) coated fabrics or vinyl, these materials are chosen for their fluid resistance, breathability, and easy cleanability. A high-quality waterproof mattress cover is indispensable for infection control and maintaining hygiene standards in medical settings. They must also be multi-stretch to reduce shear forces on the patient's skin.

Manufacturing Process: A Commitment to Precision

The manufacturing of a medical mattress is a multi-stage process that prioritizes precision, material integrity, and adherence to stringent quality controls. It involves a blend of advanced machinery and skilled craftsmanship:

- Raw Material Sourcing & Inspection: All incoming materials – foams, fabrics, zippers, threads – undergo rigorous inspection to ensure they meet specified medical-grade standards, including flammability ratings, chemical resistance, and biocompatibility.

- Foam Cutting and Contouring: High-precision CNC cutting machines are used to cut foam blocks into exact dimensions and create complex contours or zoning patterns required for pressure redistribution. This stage ensures uniformity and consistency across product lines.

- Layer Assembly and Bonding: Different foam layers, gel inserts, or air bladders are meticulously assembled and bonded using medical-grade adhesives or specialized lamination techniques. This creates the integrated support structure of the mattress.

- Cover Fabrication and Sealing: For a waterproof mattress for hospital bed, the cover material is cut to size, then seams are typically welded using radiofrequency (RF) welding or heat sealing to create impenetrable barriers against fluids. This is crucial for preventing pathogen ingress and facilitating thorough disinfection. Zippers, if used, are often designed with protective flaps to maintain fluid resistance.

- Final Assembly: The core mattress is carefully inserted into its protective cover, ensuring a snug fit. Any additional components, such as integrated pumps for air mattresses or handles, are attached.

- Quality Control & Testing: Each medical mattress undergoes a comprehensive series of tests. This includes pressure mapping to verify pressure redistribution capabilities, fluid ingress tests for waterproof integrity, durability testing (e.g., repeated compression cycles), flammability testing (e.g., CAL 117, BS 7177), and material strength tests. This rigorous inspection ensures every product leaving the facility meets the highest performance and safety benchmarks.

- Packaging: Mattresses are carefully packaged to protect them during transit and storage, often vacuum-sealed to reduce volume and shipping costs.

Inspection Standards and Certifications:

Adherence to international and national standards is non-negotiable for a medical grade mattress. Key certifications include:

- ISO 13485: This is the international standard for a quality management system specific to medical devices. It ensures that manufacturers consistently meet customer and regulatory requirements applicable to medical devices and related services.

- FDA (U.S. Food and Drug Administration) Regulations: For products marketed in the United States, compliance with FDA regulations is mandatory, ensuring devices are safe and effective for their intended use.

- CE Marking: Products sold within the European Economic Area (EEA) must bear the CE mark, indicating conformity with health, safety, and environmental protection standards.

- Flammability Standards: Compliance with specific regional flammability standards, such as California Technical Bulletin 117 (CAL 117) in the US or BS 7177 in the UK, is crucial for patient safety in healthcare facilities.

Service Life and Durability:

The expected service life of a medical mattress typically ranges from 5 to 10 years, depending on usage intensity, material quality, and adherence to maintenance protocols. High-quality materials and robust manufacturing processes contribute significantly to extended durability, ensuring the mattress maintains its therapeutic properties and structural integrity over its operational lifespan. This longevity translates into a lower total cost of ownership for healthcare providers, making the investment in a superior medical mattress a financially prudent decision.

Technical Specifications and Performance Metrics of Medical Mattresses

Understanding the technical specifications of a medical mattress is paramount for healthcare administrators and procurement specialists. These parameters directly correlate with patient safety, comfort, and the overall efficacy of pressure injury prevention strategies. A truly effective medical grade mattress is characterized by a precise combination of physical dimensions, material properties, and performance metrics.

Key Technical Parameters:

| Parameter | Description/Typical Range | Significance |

|---|---|---|

| Dimensions | Standard hospital bed sizes: typically 80" L x 36" W x 6" H (203 x 91 x 15 cm). Custom sizes available. | Ensures compatibility with existing hospital beds and patient anthropometry. Customization critical for specialized beds. |

| Weight Capacity (Bariatric) | Standard: 300-500 lbs (136-227 kg). Bariatric: 600-1000+ lbs (272-454+ kg). | Critical for patient safety and mattress durability; prevents 'bottoming out' for heavier individuals. |

| Pressure Redistribution Index (PRI) | Measured via pressure mapping (e.g., peak pressure reduction, uniformity index). Qualitatively: low, moderate, high risk. | The core function for pressure injury prevention. A lower peak pressure and more uniform distribution are ideal. |

| Fluid Resistance (Hydrostatic Head) | Typically >200 cm H2O for medical-grade covers. Measured per AAMI PB70. | Prevents fluid ingress into the mattress core, crucial for infection control and maintaining hygiene. Essential for a waterproof mattress. |

| Vapor Permeability (MVTR) | Moisture Vapor Transmission Rate, measured in g/m²/24h. Higher values (e.g., >800 g/m²/24h) indicate better breathability. | Allows skin to breathe, reducing moisture accumulation and maintaining optimal microclimate, thus reducing skin breakdown risk. |

| Fire Retardancy | Compliance with standards like CAL 117 (USA), BS 7177 (UK), NFPA 260. | Crucial for patient safety and facility fire compliance, especially in healthcare settings. |

| Material Composition | Multi-density foams (HR, Visco-elastic), air cells, gel inserts, polyurethane (PU) coated stretch covers. | Determines pressure redistribution, comfort, durability, and hygiene properties. |

| Cover Material Stretch | Multi-stretch (4-way stretch) fabric. | Reduces shear and friction forces on the patient's skin, a key factor in pressure injury development. |

| Warranty | Ranges from 2 to 10 years, covering materials and workmanship. | Indicates manufacturer's confidence in product durability and quality; ensures long-term investment protection. |

Each of these parameters plays a vital role in defining the overall performance and suitability of a medical mattress for specific patient needs and clinical environments. For instance, a best medical mattress for high-risk patients would exhibit superior pressure redistribution, high vapor permeability, and robust fluid resistance. The ability of the mattress cover to be easily cleaned and disinfected without compromising its integrity is also a non-negotiable feature for stringent hospital hygiene protocols.

Furthermore, the integration of features like modular designs, which allow for the replacement of individual sections, can significantly extend the lifespan of the mattress and reduce maintenance costs. Understanding these technical nuances enables healthcare facilities to make informed procurement decisions, ensuring that the chosen medical mattress aligns perfectly with their patient care objectives and operational requirements, ultimately enhancing patient safety and comfort while optimizing resource utilization.

Application Scenarios and Operational Advantages

The utility of a specialized medical mattress extends across a myriad of healthcare settings, each presenting unique challenges and patient requirements. From acute care hospitals to long-term care facilities and home environments, the right support surface is indispensable for effective patient management and care delivery. The operational advantages offered by high-quality medical mattresses translate directly into improved patient outcomes, enhanced staff efficiency, and significant cost savings.

Applicable Industries and Settings:

- Hospitals (Acute Care): In general wards, Intensive Care Units (ICUs), surgical recovery areas, and emergency departments, patients often have limited mobility or are completely bedridden. A medical mattress is crucial here for preventing pressure injuries, managing patient temperature, and facilitating rapid response to patient needs. The robust design and fluid-resistant properties are essential for high-turnover environments where strict infection control is paramount.

- Long-Term Care Facilities & Nursing Homes: Residents in these settings often have chronic conditions, reduced mobility, and are at high risk for skin breakdown. Mattresses designed for continuous use, offering superior pressure redistribution and ease of cleaning, are vital. The durability and longevity of a quality medical mattress minimize replacement costs over time.

- Rehabilitation Centers: Patients undergoing rehabilitation may spend extended periods in bed during recovery. Mattresses that support early mobility, provide comfort, and prevent complications like pressure ulcers contribute significantly to the recovery process. Specialized designs might accommodate specific therapeutic positions.

- Home Care: With the growing trend towards home healthcare, the demand for a reliable home medical mattress has surged. These mattresses need to offer hospital-grade performance within a residential context, focusing on ease of use, comfort for long-term residency, and features that support family caregivers, such as being lightweight and easy to manage. The presence of a famous waterproof mattress solution in home care settings offers peace of mind regarding hygiene.

- Hospice and Palliative Care: For patients requiring end-of-life care, comfort and dignity are paramount. Mattresses providing gentle pressure relief, thermal regulation, and minimal shear are selected to enhance quality of life during this sensitive period.

Operational Advantages:

- Pressure Ulcer Prevention: This is arguably the most significant advantage. Advanced pressure redistribution systems, whether static foam or dynamic air, significantly reduce the incidence of pressure injuries, which are a major source of morbidity, mortality, and increased healthcare costs. By preventing these, facilities save on treatment expenses (dressings, antibiotics, surgical debridement) and avoid potential legal liabilities.

- Infection Control: The use of an impermeable waterproof mattress for hospital bed with sealed seams and easy-to-clean surfaces is crucial for preventing the harborage and spread of pathogens. This reduces the risk of healthcare-associated infections (HAIs), a critical public health concern. Efficient cleaning protocols save valuable staff time.

- Enhanced Patient Comfort and Dignity: A well-designed medical mattress promotes patient comfort, reduces pain, and improves sleep quality, all of which contribute positively to recovery and overall well-being. This also enhances the patient experience, leading to higher satisfaction scores.

- Durability and Longevity: High-quality medical mattresses are built to withstand the rigorous demands of 24/7 use in healthcare environments. Their robust construction and medical-grade materials ensure a longer service life, reducing the frequency and cost of replacements. This leads to a lower total cost of ownership over time.

- Support for Caregivers: Many modern medical mattresses are designed to be lighter, easier to maneuver, and compatible with bed frames that offer various positions, thereby reducing physical strain on nursing staff and caregivers during patient repositioning, transfers, and daily care.

- Improved Microclimate Management: Advanced covers with high vapor permeability help dissipate heat and moisture away from the patient's skin, maintaining an optimal microclimate. This is vital for skin integrity and comfort, preventing maceration and subsequent skin breakdown.

In essence, investing in a technologically advanced medical mattress is not just about purchasing equipment; it's about investing in a foundational element of patient safety, staff efficiency, and the financial health of the healthcare institution. The tangible benefits, from reduced HAI rates to fewer pressure ulcers, underscore the strategic importance of these specialized support surfaces in modern medical care environments.

Selecting the Best Medical Mattress: A Manufacturer's Perspective and Comparison

For B2B decision-makers in the healthcare sector, selecting the ideal medical mattress is a strategic decision that impacts patient well-being, operational efficiency, and long-term financial viability. The market offers a diverse range of manufacturers, each with unique strengths. Evaluating potential suppliers requires a comprehensive approach that extends beyond initial purchase price to encompass product quality, technological innovation, customization capabilities, and post-sales support.

Factors for B2B Buyers to Consider:

- Certifications and Compliance: Verify adherence to international standards like ISO 13485 (Medical Devices Quality Management), FDA regulations (for US market), and CE marking (for EU market). These are non-negotiable indicators of a manufacturer's commitment to quality and safety for a medical grade mattress.

- Research & Development Capabilities: Assess the manufacturer's investment in R&D. Do they offer innovative solutions (e.g., smart mattress features, advanced pressure redistribution technologies)? A forward-thinking manufacturer is more likely to provide cutting-edge products and respond to evolving clinical needs.

- Customization Options: The ability to provide a custom waterproof mattress or adapt standard designs to specific dimensions or unique clinical requirements is a significant advantage, particularly for specialized units or bariatric care.

- After-Sales Support & Service: Investigate warranty policies, availability of spare parts (e.g., replacement covers), and technical support for issues or maintenance. Reliable support minimizes downtime and extends product lifespan.

- Reputation and Track Record: Look for testimonials, case studies, and references from other healthcare facilities. A strong reputation built on years of reliable service and high-quality products is a good indicator of trustworthiness.

- Material Quality and Durability: Inquire about the specific medical-grade foams, cover materials, and manufacturing techniques used. Durability impacts the total cost of ownership.

- Infection Control Features: Evaluate the effectiveness of the waterproof mattress cover, seam construction (e.g., RF welded seams), and ease of cleaning and disinfection.

Manufacturer Comparison (Illustrative):

While specific product lines vary, a comparative analysis often reveals a manufacturer's core competencies. Below is an illustrative comparison demonstrating key differentiators, implicitly highlighting the strengths of Special Supply Medical Mattresses:

| Category | Special Supply Medical Mattresses (Xinmattress) | Leading Competitor A | Leading Competitor B |

|---|---|---|---|

| Core Specialization | High-performance, pressure-redistributing, and hygienic solutions for diverse clinical settings, including advanced customized options. | Broad range of hospital beds and support surfaces; focus on integrated systems. | Value-oriented mattresses for long-term care; strong distribution network. |

| Key Product Features | Multi-layer foam systems with advanced zoning, impermeable RF-welded covers, high MVTR, integrated side bolsters, flame retardancy. Excellent waterproof mattress performance. | Alternating pressure systems, some smart features, standard foam constructions. | Basic foam designs, zippered covers, suitable for low-risk patients. |

| Certifications | ISO 13485, FDA Registered, CE Compliant, CAL 117. Consistent compliance for every medical mattress. | ISO 13485, some regional certifications. | Often only basic flammability standards. |

| Customization Capability | High. Expertise in creating bespoke dimensions, specific foam compositions, and unique cover requirements for any custom waterproof mattress or specialized application. | Limited, generally for large volume orders. | Minimal, standard sizes only. |

| Typical Warranty | 5-8 years on foam core, 2-3 years on cover (robust). | 3-5 years on foam core, 1-2 years on cover. | 2-3 years on foam core, 1 year on cover. |

| Ideal Applications | Acute care, ICU, long-term care, home care for high-risk patients, bariatric, specialized clinical departments requiring precision and superior hygiene. | General hospital wards, some critical care. | Low-risk long-term care, general patient comfort. |

Special Supply Medical Mattresses distinguishes itself through its unwavering commitment to producing a superior medical grade mattress that addresses the evolving demands of modern medical care. Our focus on precision engineering, the utilization of advanced materials, and comprehensive quality control processes ensure that each product delivers exceptional pressure redistribution, unparalleled fluid resistance, and longevity. We understand that every healthcare environment has unique needs, which is why our robust customization capabilities for a custom waterproof mattress set us apart, allowing facilities to procure solutions precisely tailored to their patient populations and operational workflows. This strategic approach minimizes compromise, ensuring that facilities invest in the most effective and durable support surfaces available on the market, thereby enhancing patient safety and optimizing long-term value.

Customization and Bespoke Solutions for Diverse Medical Needs

In the realm of B2B healthcare procurement, the "one-size-fits-all" approach is rapidly becoming obsolete, especially when it comes to critical patient support surfaces like the medical mattress. Modern healthcare facilities, from specialized surgical centers to bariatric units and pediatric hospitals, often require solutions that deviate from standard specifications. This is where the capability for customization and bespoke solutions becomes a paramount advantage, ensuring that every patient receives optimal care tailored to their unique physiological and clinical requirements.

The Imperative for Customization:

Customization in medical mattresses addresses several critical needs:

- Unique Bed Frame Dimensions: Many specialized beds, such as those in bariatric units, extended care facilities, or older hospital wings, may have non-standard dimensions that require a precisely fitted medical mattress. A gap between the mattress and the bed frame can pose entrapment risks and compromise patient safety.

- Specialized Patient Populations: Bariatric patients require mattresses with higher weight capacities and enhanced pressure redistribution to prevent bottoming out. Pediatric patients need smaller, appropriately sized mattresses that maintain therapeutic benefits. Patients with specific orthopedic conditions may benefit from custom zoning or firmness levels.

- Integration with Medical Equipment: Some clinical setups require mattresses with cut-outs for medical tubing, specific connections for air pumps (for alternating pressure systems), or unique features to accommodate diagnostic imaging equipment.

- Environmental & Infection Control Challenges: While all medical mattresses aim for hygiene, some environments might demand specific antimicrobial additives, unique fluid barrier properties beyond standard, or materials resistant to certain harsh cleaning agents. For example, a custom waterproof mattress could be designed for extreme conditions or specific chemical resistance.

Aspects of Customization Offered by Leading Manufacturers:

- Dimensions: Beyond standard sizes, manufacturers can produce mattresses in exact lengths, widths, and depths to fit any bed frame or stretcher. This includes varying heights for different levels of patient acuity or care needs.

- Foam Composition and Layering: Customization allows for specific combinations of foam types (e.g., higher density base foam for bariatric support, thicker visco-elastic layers for enhanced pressure relief). Manufacturers can tailor the firmness and resilience of different zones within the mattress.

- Pressure Zone Configuration: Based on clinical evidence or specific patient risk profiles, pressure redistribution zones can be customized. This involves altering the foam cuts or layering patterns in areas prone to pressure injuries, such as the sacrum, heels, and occiput.

- Cover Materials and Features: While a waterproof mattress is standard, customization can involve selecting specific levels of fluid resistance, breathability (MVTR), or even color-coding for different hospital departments. Features like integrated side bolsters, specific zipper placements, or built-in carrying handles can also be custom-added.

- Integrated Technologies: For advanced applications, manufacturers can integrate specific sensor technologies for continuous pressure mapping, patient movement tracking, or even temperature regulation, connecting to existing hospital monitoring systems.

Application Cases Demonstrating Customization Value:

- Bariatric Care Unit: A large metropolitan hospital approached us needing mattresses for their new bariatric wing. Standard mattresses were insufficient in terms of weight capacity and often bottomed out, leading to increased pressure injury rates. We provided a medical mattress with an extra-dense core and a thicker, multi-layered visco-elastic top, reinforced perimeter, and a reinforced waterproof mattress cover, specifically designed to support patients up to 1000 lbs, significantly reducing pressure injury incidence.

- Pediatric ICU: A children's hospital required smaller, softer mattresses for their infant and toddler ICU beds. Our solution involved custom-sized mattresses with a gentler foam composition suitable for delicate skin and lighter body weights, ensuring optimal pressure relief without sacrificing support, alongside a fully sealed, wipeable cover for robust infection control.

- Home Hospice Program: For a regional home hospice program, we developed a lightweight home medical mattress that was easy for caregivers to manage and transport, yet provided the superior pressure redistribution of a clinic-grade model. These were often a simpler, yet effective, type of famous waterproof mattress solution optimized for residential use.

The ability to provide highly specific and effective solutions showcases a manufacturer's expertise and commitment to partner with healthcare providers. Special Supply Medical Mattresses prides itself on its robust engineering and manufacturing capabilities, enabling us to deliver tailor-made medical mattress solutions that precisely meet the diverse and evolving needs of advanced medical care environments, ensuring unparalleled patient safety and therapeutic efficacy.

Enhancing Trust and Ensuring Quality: Certifications, Support, and FAQ

Building and maintaining trust in the B2B healthcare sector is paramount. For a manufacturer of a medical mattress, this trust is underpinned by transparent adherence to industry standards, robust quality assurance, reliable customer support, and clear commitments regarding product longevity and performance. These elements collectively establish a manufacturer's authority and trustworthiness, assuring healthcare providers that their investment in a medical grade mattress is both sound and sustainable.

Authoritativeness through Certifications and Industry Standing:

- ISO 13485 Certified Quality Management System: This certification is the cornerstone of our commitment to quality. It signifies that our entire manufacturing process, from design to delivery, adheres to the most stringent international standards for medical devices. Every medical mattress produced undergoes rigorous quality control at each stage.

- FDA Registration and CE Marking: Our products are registered with the U.S. Food and Drug Administration (FDA) and bear the CE mark for the European market. These regulatory compliances confirm that our mattresses meet essential health, safety, and environmental protection requirements for global distribution.

- Strategic Partnerships: Over [X] years in the industry (Note: X should be replaced with actual years of service if known, otherwise generic is fine), we have cultivated strong relationships with leading healthcare networks and distributors, a testament to our reliability and product excellence. Our long-standing commitment to the medical community reinforces our position as an authoritative supplier of critical medical equipment.

- Test Data and Clinical Efficacy: We regularly conduct and collaborate on studies demonstrating the efficacy of our pressure redistribution systems. Our mattresses are designed based on evidence-based practice to deliver superior clinical outcomes, supported by internal testing data on pressure mapping, fluid resistance, and durability.

Trustworthiness through Support and Transparency:

Beyond certifications, our dedication to client support and transparent practices ensures complete trust:

- Comprehensive Warranty Promise: We stand behind the durability and performance of our Special Supply Medical Mattresses with a robust warranty. Typically, our foam cores come with a 5-8 year warranty, and our highly durable waterproof mattress covers are warranted for 2-3 years, ensuring your investment is protected. Specific terms are clearly outlined and honored.

- Efficient Delivery Cycle: Understanding the critical nature of healthcare supply chains, we maintain optimized production and logistics to ensure timely delivery. Standard orders for a medical mattress are typically fulfilled within 2-4 weeks, with expedited options available for urgent requirements. Our efficient supply chain minimizes downtime for facilities.

- Dedicated Customer Support: Our expert customer service and technical support teams are readily available to assist with product selection, technical queries, maintenance advice, and warranty claims. We offer comprehensive after-sales support to ensure seamless integration and long-term satisfaction with our products.

Frequently Asked Questions (FAQ):

- Q: How often should a medical mattress be replaced?

A: The lifespan of a medical mattress varies based on usage and material quality. High-quality foam cores can last 5-10 years. We recommend regular inspection for signs of wear, loss of firmness, or compromise to the waterproof mattress cover, which may indicate a need for replacement or refurbishment. - Q: What is the best way to clean and disinfect the medical mattress?

A: Our medical mattress covers are designed for easy cleaning. Use a mild detergent and water solution or a healthcare-approved disinfectant wipe. Ensure the cover is completely dry before remaking the bed. Avoid abrasive cleaners or excessive scrubbing, especially on a famous waterproof mattress. - Q: Are your mattresses suitable for bariatric patients?

A: Yes, we offer specialized bariatric models of the best medical mattress designed with higher weight capacities and reinforced support layers to prevent bottoming out and provide effective pressure redistribution for heavier patients. Custom solutions are also available. - Q: What is the difference between a static and an alternating pressure medical mattress?

A: A static medical mattress uses foam or gel to redistribute pressure, while an alternating pressure mattress uses a system of inflating and deflating air cells to continuously change pressure points, promoting blood flow. Alternating pressure mattresses are typically recommended for higher-risk patients. - Q: Can I get a custom waterproof mattress for our unique bed frames?

A: Absolutely. Customization is a key strength of Special Supply Medical Mattresses. We can manufacture a custom waterproof mattress to precise dimensions and specifications, ensuring a perfect fit and optimal performance for any unique bed frame or specialized clinical requirement.

Through our steadfast commitment to authoritative certifications, transparent communication, and unparalleled customer support, we aim to be more than just a supplier; we strive to be a trusted partner in providing superior medical care solutions. Our dedication ensures that every Special Supply Medical Mattress contributes effectively to patient safety, comfort, and the operational excellence of healthcare facilities worldwide.

Conclusion

The contemporary healthcare landscape places an unprecedented emphasis on patient safety, infection control, and the efficient allocation of resources. Within this context, the medical mattress stands as a foundational pillar, directly influencing patient outcomes, caregiver workload, and the overall operational integrity of healthcare facilities. The evolution of the medical mattress from a simple bedding item to a sophisticated medical device underscores the advancements in materials science, engineering, and clinical understanding dedicated to mitigating pressure injuries and ensuring optimal patient comfort.

By meticulously designing and manufacturing each medical grade mattress to meet rigorous international standards, employing advanced materials, and embracing cutting-edge manufacturing processes, leading manufacturers ensure superior pressure redistribution, fluid resistance, and durability. The availability of specialized solutions, including the indispensable waterproof mattress and highly adaptable custom waterproof mattress options, allows healthcare providers to implement tailored care strategies across diverse patient populations and clinical environments, from acute hospital settings to long-term care facilities and the growing segment of home medical mattress applications.

For B2B decision-makers, choosing the right supplier for a medical mattress is not merely a procurement task but a strategic investment in patient well-being and operational resilience. A manufacturer's adherence to stringent quality certifications, robust after-sales support, and a proven track record of delivering innovative, reliable products are critical indicators of long-term value. Special Supply Medical Mattresses is committed to setting the benchmark in this vital sector, providing solutions that not only meet but exceed the complex demands of modern medical care. Our dedication to precision, performance, and partnership ensures that every mattress contributes significantly to a safer, more comfortable, and therapeutically effective environment for patients worldwide, ultimately upholding the highest standards of healthcare excellence.

References

- National Pressure Ulcer Advisory Panel (NPUAP), European Pressure Ulcer Advisory Panel (EPUAP), and Pan Pacific Pressure Injury Alliance (PPPIA). Prevention and Treatment of Pressure Ulcers: Clinical Practice Guideline. 3rd ed. 2014.

- International Organization for Standardization (ISO) 13485:2016. Medical devices — Quality management systems — Requirements for regulatory purposes.

- Agency for Healthcare Research and Quality (AHRQ). Preventing Pressure Ulcers in Hospitals: A Toolkit for Improving Quality of Care. 2014.

- California Technical Bulletin 117-2013. Requirements, Test Procedures and Apparatus for Testing the Smolder Resistance of Materials Used in Upholstered Furniture.

- Black, J. M., et al. "Pressure Ulcers: Prevention, Assessment, and Management." Nursing Standard, vol. 28, no. 12, 2013, pp. 58-68.

-

best-cleaning-practices-for-a-hospital-mattress-doubleNewsAug.22,2025

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025

-

Innovative Wave Mattresses for Ultimate ComfortNewsAug.08,2025

-

High-Quality Mattresses for Hospital BedsNewsAug.08,2025

-

High-Quality Mattresses for Every NeedNewsAug.08,2025

-

Healthcare Foam Mattress: Sleep Better, Heal FasterNewsAug.08,2025

-

Cube Mattress for Daily ComfortNewsAug.08,2025