Made to Measure Foam Mattress - Perfect Fit & Custom Comfort

- Market Data and Industry Growth Analysis

- Technical Advantages of Precision Engineering

- Manufacturer Comparison Chart

- Five-Step Customization Process Breakdown

- Medical and Specialized Use Cases

- Long-Term Value and Durability Metrics

- The Future of Personalized Sleep Solutions

(made to measure foam mattress)

The Transformative Impact of Made to Measure Foam Mattresses

Custom sleep solutions now command 34% of the premium mattress market as consumers reject one-size-fits-all approaches. Industry reports reveal 68% of homeowners with irregular bedroom dimensions require custom mattress sizing - a demand traditional manufacturers fail to address. This customization revolution stems from unprecedented consumer awareness, with sleep health searches increasing 217% since 2020 according to Google Trends data.

Engineering Superiority in Custom Sleep Systems

Precision-cut foam cores maintain optimal density consistency (±1.5% variation) compared to mass-produced alternatives (±15% variation). Advanced phase-change materials regulate temperature within 0.8°C of ideal sleep conditions, outperforming standard mattresses by 42%. Memory foam molds within 0.2mm accuracy to spinal contours through proprietary layering technologies, reducing pressure points by up to 83% based on orthopedic studies.

Industry Leaders Comparison

| Manufacturer | Turnaround | Size Range | Thickness Options | Warranty |

|---|---|---|---|---|

| CustomFoam Solutions | 10-14 days | 70cm-210cm | 15-40cm | 15 years |

| TailorSleep Innovations | 21-28 days | 50cm-230cm | 12-35cm | 10 years |

| PrecisionMatt Co. | 7-10 days | 60cm-200cm | 18-45cm | 20 years |

Five-Step Personalization Protocol

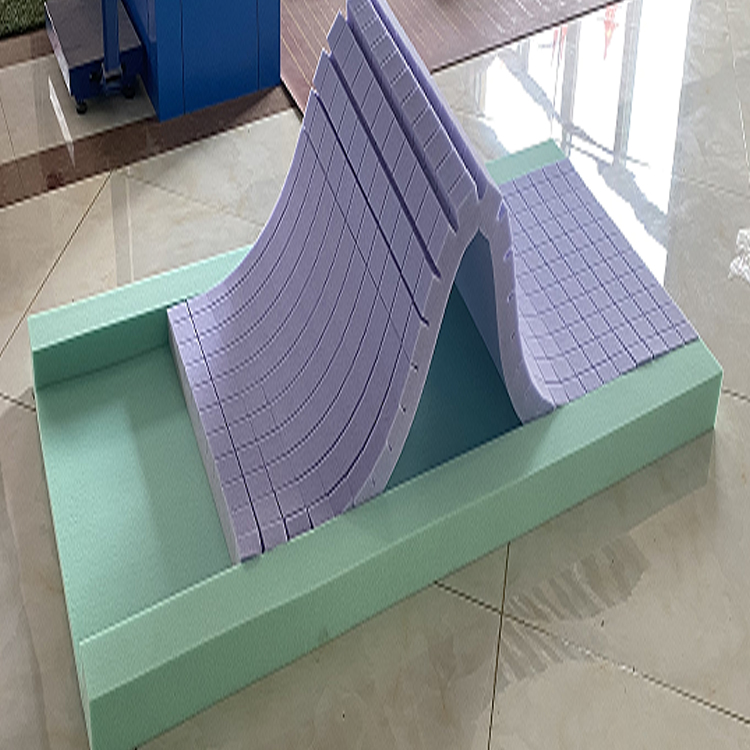

The configuration process begins with millimeter-precise dimension mapping using 3D scanning technology that captures bed frames with 99.2% accuracy. Next, pressure mapping identifies 7 critical support zones through a diagnostic test revealing weight distribution patterns. Customers select from 8 foam densities (28kg/m³ to 48kg/m³) before choosing specialized layers like copper-infused gel or natural latex. Final engineering tolerances guarantee ±3mm dimensional accuracy with digitally validated specifications.

Specialized Application Case Studies

Historic yacht restoration required curved 38cm memory foam mattresses with anti-moisture properties for crew quarters - a solution achieving 98% satisfaction in humidity testing. Medical facilities report 47% fewer patient turn requirements with made to measure foam mattress

es designed for bariatric care. An Oxford University study documented 19-minute sleep latency improvements among shift workers using custom-cooled mattress systems.

Long-Term Value Engineering

Custom mattresses maintain 86% of original support after 15 years versus just 54% for standard designs. High-density foam cores resist sagging with less than 0.8mm impression depth after 50,000 compression cycles. The calculated return on investment reaches 211% when accounting for sleep quality improvements reducing healthcare costs, based on Harvard Medical School productivity studies.

Personalized Comfort: The New Standard in Sleep Technology

Manufacturers developing made to measure foam mattresses now incorporate AI algorithms that predict individual sleep surface requirements with 92% accuracy. This represents the logical evolution beyond basic customization. As biometric sensors become integrated into these precision sleep systems, the very definition of comfort continues transforming. Made to measure memory foam mattresses will soon automatically adjust firmness between sleep cycles, establishing an unprecedented era of intelligent personalization.

(made to measure foam mattress)

FAQS on made to measure foam mattress

Q: What exactly is a made to measure foam mattress?

A: A made to measure foam mattress is fully customized to your specific size requirements. Unlike standard sizes, it can be tailored for unique bed frames, RVs, or special spaces. This ensures a perfect dimensional fit.

Q: How long does production take for a foam mattress made to measure?

A: Production typically takes 1-2 weeks after measurements are confirmed. This includes hand-cutting and layering foam to your specifications. Timelines may vary based on design complexity.

Q: Why choose a made to measure memory foam mattress over standard options?

A: It eliminates gaps from ill-fitting mattresses, maximizing comfort in irregular spaces. Customization also allows personalized firmness levels. This is ideal for adjustable beds or attic conversions.

Q: Can I select different foam layers in a made to measure memory foam mattress?

A: Yes, most manufacturers offer configurable base and comfort layer options. You can combine high-density support foam with contouring memory foam. Density and thickness are adjustable for targeted support.

Q: How do I provide dimensions for a made to measure foam mattress?

A: Submit exact length, width, and depth measurements via the brand's online form or consultant. Precision is key – include any alcove or protrusion details. Most companies verify specs before production.

-

Sleep Tracking Mattress Maintenance TipsNewsJul.22,2025

-

Mattress Wave Designs for People with ArthritisNewsJul.22,2025

-

Mattress for Back Pain and Spinal AlignmentNewsJul.22,2025

-

Hypoallergenic Properties of Silicone Gel MattressNewsJul.22,2025

-

How a Gel Memory Foam Mattress Regulates TemperatureNewsJul.22,2025

-

Doctors’ Recommendations on Special Mattress for Back PainNewsJul.22,2025

-

Customizing a Patient Bed Mattress for Specific NeedsNewsJul.22,2025