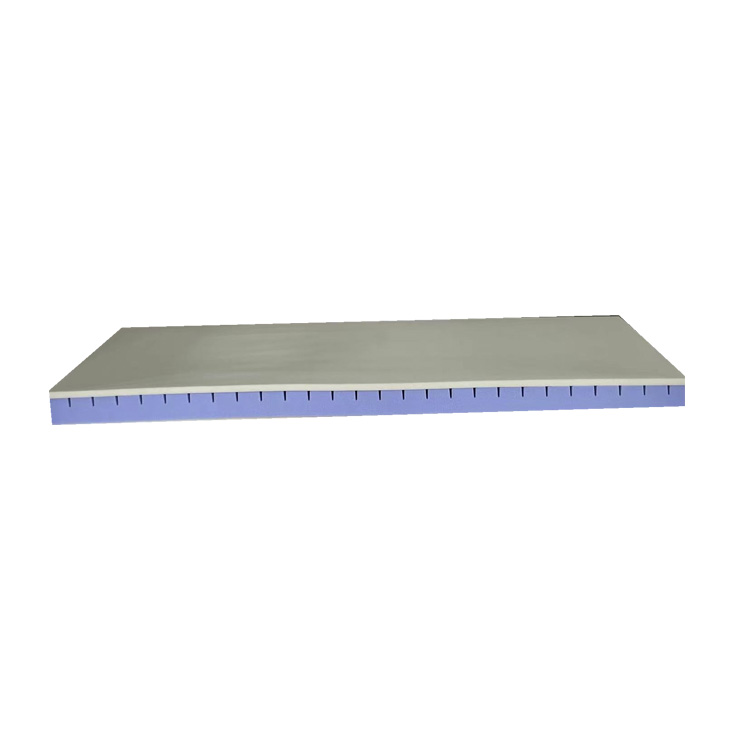

anti-decubitus air mattress factory

The Importance of Anti-Decubitus Air Mattresses An Overview of Their Manufacturing

In today's healthcare landscape, tackling the challenges of bedsores, also known as pressure ulcers or decubitus ulcers, has become increasingly crucial, especially for individuals with limited mobility. One innovative solution that has gained prominence is the anti-decubitus air mattress. This article explores what these mattresses are, their manufacturing process, and their significance in healthcare settings.

Understanding Anti-Decubitus Air Mattresses

Anti-decubitus air mattresses are specialized mattresses designed to reduce the risk of pressure ulcers in bedridden patients. They employ air-filled chambers that can be inflated and deflated in a strategic manner to redistribute pressure points on the body. The competition among various manufacturers in this field has led to significant advancements in technology, resulting in mattresses that offer better comfort, support, and effectiveness.

These mattresses are vital in hospitals, nursing homes, and home care environments, particularly for patients who are unable to shift their weight frequently. The adjustable airflow allows for optimal body positioning and enhances blood circulation, thus minimizing the risk of skin breakdown. By continuously changing the pressure points on the patient's body, these mattresses significantly aid healing processes and contribute to patient comfort.

The Manufacturing Process

The manufacturing of anti-decubitus air mattresses involves a series of strategic steps to ensure high quality, durability, and effectiveness. Here is a streamlined overview of the key elements involved in their production.

1. Material Selection High-quality materials are essential for the manufacture of air mattresses. Manufacturers typically use durable, hypoallergenic fabrics that can withstand frequent use and are easy to clean. The materials must also be breathable to prevent the buildup of moisture, which can lead to skin issues.

anti-decubitus air mattress factory

2. Design and Technology Innovators continuously work on developing new designs that incorporate advanced technology. This might include innovative valve systems that allow for easier inflation and deflation, as well as sensors that adjust the pressure based on the patient’s weight and movements. The design phase also considers ease of use, ensuring caregivers can quickly adjust settings.

3. Production Techniques Manufacturing processes may involve a combination of automated machinery and skilled craftsmanship. High precision is key in sealing seams to prevent air leaks and ensuring that the mattress chambers are uniformly constructed for optimal functionality. Quality control measures are also implemented at this stage to ensure that every mattress meets the required standards.

4. Testing and Quality Assurance Before the mattresses are shipped out, thorough testing is conducted to ensure their effectiveness and safety. This includes stress testing for durability and ensuring that the air pressure regulation systems function correctly. Additionally, compliance with regulatory standards for medical devices is verified, ensuring that the product is safe for patient use.

5. Packaging and Distribution Once the mattresses pass quality assurance, they are carefully packaged to prevent damage during transportation. Efficient supply chain management ensures that these products are distributed to healthcare facilities promptly, enabling caregivers to provide essential support to their patients.

The Impact of Anti-Decubitus Air Mattresses

The significance of anti-decubitus air mattresses cannot be understated. They play a critical role in enhancing patient care, improving comfort, and reducing healthcare costs associated with treating pressure ulcers. By investing in high-quality mattresses, healthcare facilities can minimize the risk of complications, enhance recovery times, and ultimately improve the quality of life for those who are bedridden.

In summary, the anti-decubitus air mattress manufacturing sector reflects a blend of technology, quality materials, and meticulous engineering. As awareness of bedsores continues to grow, so does the commitment of manufacturers to develop mattresses that contribute positively to patient well-being. As the industry continues to evolve, it is exciting to anticipate further innovations that will enhance both patient care and the effectiveness of healthcare practices worldwide.

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025

-

Innovative Wave Mattresses for Ultimate ComfortNewsAug.08,2025

-

High-Quality Mattresses for Hospital BedsNewsAug.08,2025

-

High-Quality Mattresses for Every NeedNewsAug.08,2025

-

Healthcare Foam Mattress: Sleep Better, Heal FasterNewsAug.08,2025

-

Cube Mattress for Daily ComfortNewsAug.08,2025

-

How Hospital Mattress Choices Directly Impact Patient Comfort and CareNewsAug.05,2025