Waterproof Medical Mattress for Superior Home & Hospital Care

The Evolving Landscape of Medical Mattresses: Industry Trends and Innovations

The global healthcare sector is experiencing a significant paradigm shift, driven by an aging population, rising chronic disease prevalence, and an increased focus on patient-centric care. Within this evolving landscape, the demand for specialized support surfaces, particularly the medical mattress, has surged. These advanced mattresses are no longer merely comfort devices; they are critical components in therapeutic interventions, pressure ulcer prevention, and patient rehabilitation, both in acute care settings and in the burgeoning home medical care market.

Industry trends indicate a clear move towards intelligent and highly specialized solutions. We are seeing accelerated integration of advanced materials such as viscoelastic foams, gel-infused layers, and air-cell technology designed for dynamic pressure redistribution. Furthermore, the emphasis on infection control has propelled innovations in waterproof mattress solutions, with materials that are not only impermeable but also breathable and easy to sanitize. The market is also seeing a rise in custom waterproof mattress solutions, tailored to specific clinical needs and patient demographics, ranging from bariatric support to pediatric applications. The drive for sustainability and enhanced durability also influences material selection and manufacturing processes, aiming for longer service life and reduced environmental impact.

The market for medical grade mattress products is projected to grow substantially, driven by technological advancements, increasing healthcare expenditure, and a greater awareness among healthcare providers of the direct correlation between high-quality support surfaces and patient outcomes. Innovations in sensor technology for real-time pressure monitoring and smart mattress systems are also on the horizon, promising even more personalized and proactive patient care.

The Precision Behind Patient Comfort: Medical Mattress Manufacturing Process

The production of a high-quality medical mattress is a complex process demanding precision, adherence to stringent medical standards, and advanced material science. It significantly deviates from conventional mattress manufacturing due to critical performance requirements like pressure redistribution, infection control, and durability. Our Special Supply Medical Mattresses undergo a rigorous, multi-stage manufacturing process to ensure superior performance and reliability.

Process Flow Overview:

- Material Sourcing & Quality Inspection: We begin by sourcing medical-grade raw materials, including specialized foams (high-resilience, memory, viscoelastic, gel-infused), advanced fluid-proof and breathable fabrics (e.g., polyurethane-coated nylon/polyester), and reinforced stitching threads. Each batch undergoes rigorous incoming quality inspection, verifying properties such as density, compression deflection, elasticity, tear strength, and biocompatibility, against ISO 10993 standards.

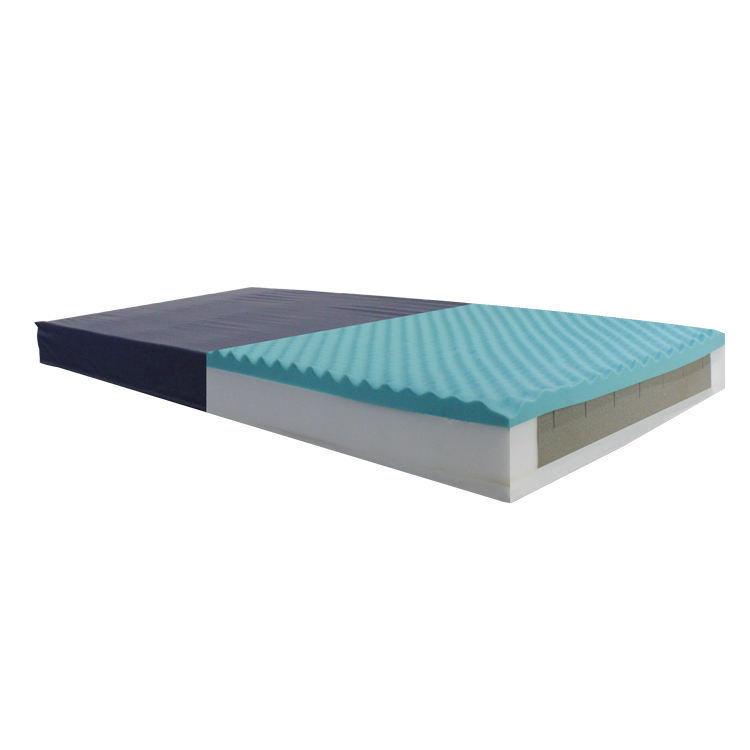

- Precision Cutting & Layering: Using advanced CNC cutting machines, foam blocks and fabric rolls are precisely cut to specified dimensions. This ensures consistent sizing and eliminates material waste. Different foam layers (base support, pressure redistribution, comfort top) are then carefully stacked according to the mattress design, often incorporating varying densities and structures to optimize support and pressure relief.

- Adhesion & Bonding: Layers are bonded using medical-grade, solvent-free, non-toxic adhesives. This process is critical for maintaining the structural integrity of the mattress core, preventing shifting of layers, and ensuring long-term durability. Specialized lamination techniques are employed to fuse different material characteristics seamlessly.

- Cover Fabrication & Assembly: The external cover, often the primary defense against fluids and contaminants, is meticulously cut and sewn. This involves specialized industrial sewing machines capable of producing durable seams, often with welded or heat-sealed construction for truly waterproof integrity. Zippers, typically fluid-resistant or concealed, are integrated for ease of removal and cleaning. The cover materials are chosen for their barrier properties, breathability, and ease of cleaning, ensuring a famous waterproof mattress.

- Final Assembly & Internal Components: For dynamic systems (e.g., alternating pressure mattresses), internal air bladders, pumps, and sensors are integrated at this stage, requiring precision electronics assembly. The core layers are encased within the fabricated cover.

-

Comprehensive Testing & Quality Assurance: Every finished medical mattress undergoes extensive testing:

- Pressure Mapping: Using advanced pressure mapping systems, the mattress's ability to redistribute pressure is assessed under various load conditions, ensuring optimal performance in preventing pressure ulcers, aligning with NPUAP guidelines.

- Durability Testing: Simulating years of use through cyclic loading and impact tests to confirm structural integrity and service life, often adhering to ASTM F2328 standards.

- Fluid Resistance: Testing for impermeability to liquids, crucial for maintaining hygiene and preventing contamination, meeting ISO 16603/16604 standards.

- Flame Retardancy: Compliance with fire safety standards like CAL 117 or BS 7177.

- Biocompatibility: Ensuring materials are non-irritating and non-sensitizing for patient contact.

- Packaging & Sterilization (Optional): Mattresses are carefully packaged, often compressed and rolled for efficient shipping. For specific medical environments, terminal sterilization processes might be applied.

This meticulous process ensures our mattresses consistently meet or exceed global standards such as ISO 13485 (Medical Devices Quality Management), FDA regulations (Class I/II medical devices), and CE marking requirements. With an average service life exceeding 5-7 years in typical clinical settings, these mattresses offer long-term value. Target industries include hospitals (acute care, long-term care), rehabilitation centers, home healthcare providers, and specialized clinics. The advantages in typical application scenarios are clear: enhanced patient safety, significant reduction in pressure injury incidence, superior infection control, and improved clinical outcomes leading to energy saving in terms of reduced nursing time and treatment costs, along with exceptional resistance to corrosion from bodily fluids and cleaning agents.

Technical Specifications and Performance Parameters

Understanding the intrinsic technical specifications of a medical mattress is crucial for healthcare procurement professionals and clinicians. Our Special Supply Medical Mattresses are engineered for optimal performance, balancing patient comfort with critical therapeutic requirements. Below are key parameters and specifications:

Product Specification Table: Special Supply Medical Mattresses

| Parameter | Specification | Standard / Test Method |

|---|---|---|

| Dimensions (Standard) | 200cm L x 90cm W x 15cm H (Customizable) | ISO 8601 (Adaptable) |

| Weight Capacity | Up to 250 kg (Bariatric options available) | EN 60601-2-52 |

| Core Material | Multi-layered High-Resilience (HR) Foam and Viscoelastic (Memory) Foam with perimeter reinforcement | ASTM D3574 (Density, ILD) |

| Cover Material | Bi-elastic Polyurethane (PU) coated fabric; waterproof, vapor permeable, anti-bacterial, anti-fungal | ISO 16603, ISO 20743, JIS L 1902 |

| Pressure Redistribution | Average Interface Pressure below 32 mmHg (according to NPUAP guidelines for pressure injury prevention) | Pressure mapping with Xsensor/FSA (industry standard) |

| Fire Retardancy | Compliant with leading international standards | CAL 117-2013, BS 7177 (crib 5) |

| Cleaning & Disinfection | Wipeable with standard medical disinfectants; cover machine washable up to 95°C | Manufacturer protocols, CDC guidelines |

| Certifications | CE, FDA (listing), ISO 13485, REACH, OEKO-TEX Standard 100 | Accredited Body Audits |

These specifications underscore the advanced engineering and adherence to rigorous quality standards, ensuring that each medical mattress delivers consistent, high-level performance in diverse clinical environments. The bi-elastic waterproof mattress cover is specifically designed to reduce shear and friction forces, critical factors in pressure injury development, while maintaining breathability for patient comfort and skin integrity. The multi-layered foam structure optimizes weight distribution, providing superior pressure relief compared to standard foam mattresses, making it an ideal best medical mattress solution.

Application Scenarios and Technical Advantages

The versatility and specialized features of a medical mattress make it indispensable across a spectrum of healthcare settings. Its design addresses the critical needs of patients requiring extended bed rest or those at high risk of pressure injuries.

Key Application Scenarios:

- Acute Care Hospitals: Essential in general wards, intensive care units (ICUs), and post-operative recovery rooms, where patients often have limited mobility and require immediate medical care. The pressure-redistributing properties are critical for preventing skin breakdown during short or extended hospital stays.

- Long-Term Care Facilities & Nursing Homes: A primary choice for residents with chronic conditions, advanced age, or neurological impairments, who spend significant time in bed. The durability and ease of cleaning of a medical grade mattress are paramount in these environments.

- Home Healthcare: With the growth of home medical mattress solutions, these mattresses enable patients to receive high-quality care in a familiar environment. They are particularly beneficial for individuals recovering from surgery, managing chronic illnesses, or requiring palliative care.

- Rehabilitation Centers: Supporting patients recovering from injuries, strokes, or other conditions requiring physical therapy and prolonged immobilization. The mattress aids in comfort and prevents secondary complications.

- Specialized Clinics: Including bariatric clinics, wound care centers, and oncology units, where patient-specific needs dictate highly specialized support surfaces.

Technical Advantages:

- Superior Pressure Redistribution: Engineered foam layers (e.g., viscoelastic, high-resilience) effectively distribute body weight over a larger surface area, reducing peak pressure points. This dramatically lowers the risk of pressure injury (bed sore) development, a major concern in patient care. This is a hallmark of a best medical mattress.

- Advanced Infection Control: The waterproof mattress cover, made from bi-elastic PU-coated fabrics, acts as an impermeable barrier against fluids, blood, and contaminants. This prevents pathogens from penetrating the mattress core, facilitating easy cleaning and disinfection, thereby reducing the risk of healthcare-associated infections (HAIs). Its anti-bacterial and anti-fungal properties provide an additional layer of protection, making it a truly famous waterproof mattress.

- Enhanced Patient Comfort & Support: The multi-layered construction provides optimal comfort, conforming to the patient's body shape while offering stable support. This reduces discomfort, improves sleep quality, and contributes to overall patient well-being, crucial for recovery.

- Durability & Longevity: Constructed with high-density, medical-grade foams and robust covers, these mattresses are designed to withstand the rigorous demands of healthcare environments, including frequent cleaning, heavy usage, and repeated patient transfers. This translates to a longer service life and better return on investment.

- Shear and Friction Reduction: The bi-elasticity of the cover material minimizes shear and friction forces when patients are repositioned, a key factor in preventing skin tears and pressure injuries.

- Breathability: Despite being waterproof, the vapor-permeable cover allows air to circulate, managing microclimate and reducing moisture buildup, which is vital for skin health.

- Safety Compliance: Strict adherence to international fire safety standards (e.g., CAL 117, BS 7177) and biocompatibility ensures patient and facility safety.

Vendor Comparison and Customized Solutions

Selecting the right medical mattress vendor is a critical decision for healthcare providers, impacting patient outcomes, operational efficiency, and long-term cost-effectiveness. A comprehensive evaluation goes beyond initial price, focusing on product quality, technical innovation, customization capabilities, and after-sales support.

Key Factors in Vendor Comparison:

| Feature/Criterion | Standard Vendor Offerings | Our Special Supply Medical Mattresses |

|---|---|---|

| Pressure Redistribution Capability | Basic foam or static air systems, limited efficacy for high-risk patients. | Advanced multi-layered viscoelastic and HR foams; proven interface pressure reduction for all risk levels. |

| Infection Control Features | Water-resistant covers, may lack full impermeability or advanced anti-microbial properties. | Fully waterproof, vapor-permeable, bi-elastic PU covers with integrated anti-bacterial and anti-fungal treatment. Heat-sealed/welded seams for maximum barrier protection. |

| Durability & Service Life | 2-4 years, prone to sagging or material degradation with frequent cleaning. | 5-7+ years, high-density foams and robust covers designed for repeated disinfection and heavy use. ASTM F2328 tested. |

| Certifications & Compliance | Basic national standards, limited international recognition. | CE, FDA Listed, ISO 13485, CAL 117-2013, BS 7177 (crib 5), REACH, OEKO-TEX 100. |

| Customization Options | Limited to standard sizes, few material variations. | Extensive customization for dimensions, foam density, layering, cover materials, and bariatric/pediatric specifications. |

| Warranty & Support | Standard 1-2 year warranty, basic customer service. | Comprehensive 5-year warranty on core, 2-year on cover. Dedicated B2B support, technical assistance. |

Customized Solutions: Tailoring the Best Medical Mattress

Recognizing that healthcare needs are rarely one-size-fits-all, we specialize in providing custom waterproof mattress solutions. This capability allows healthcare facilities to procure mattresses perfectly aligned with their specific clinical demands, patient demographics, and existing equipment (e.g., specialized hospital beds).

- Dimension Customization: Tailored to fit non-standard bed frames, including bariatric beds, pediatric cribs, gurney mattresses, or operating theatre tables.

- Material & Firmness Adjustment: Varying foam densities and layering configurations to address specific pressure injury risks, patient weights, or comfort preferences. For instance, firmer edges for patient egress/ingress or softer zones for sensitive areas.

- Cover Material Options: While our standard cover is premium, options may include specific color coding for different departments, integrated patient identification windows, or specialized fabric treatments for extreme chemical resistance.

- Integrated Features: Custom cut-outs for medical devices (e.g., drainage bags), reinforced handles for easier handling, or specific corner designs for adjustable bed frames.

Our technical team collaborates closely with clients to understand their precise requirements, leveraging our advanced manufacturing capabilities to deliver bespoke medical mattress solutions that uphold the highest standards of quality and performance. This commitment to customization ensures that every home medical mattress or hospital bed mattress we supply is truly optimized for its intended use.

Application Case Studies: Proving Efficacy in Real-World Medical Care

The real measure of a medical mattress lies in its performance within active clinical environments. Our Special Supply Medical Mattresses have consistently demonstrated superior efficacy in various challenging settings, contributing significantly to improved patient outcomes and operational efficiencies.

Case Study 1: Large Urban Hospital System (Acute Care)

A metropolitan hospital network, encompassing 1,200 beds across multiple specialties, faced persistent challenges with pressure injury rates, particularly among their high-risk patient populations in ICU and general surgical wards. Their existing mattresses, despite being "medical grade," showed signs of premature wear and suboptimal pressure redistribution, leading to increased nursing workload and extended patient recovery times.

- Intervention: The hospital replaced 300 existing support surfaces with our Special Supply Medical Mattresses over an 18-month period, prioritizing high-risk units. In-service training was provided to nursing staff on the mattress's features and proper care protocols.

-

Results (Post-Implementation, 12 months):

- A 40% reduction in hospital-acquired pressure injuries (HAPIs) across the target units.

- Improved patient comfort scores, as indicated by patient satisfaction surveys.

- Reported ease of cleaning and disinfection by environmental services, leading to a 15% reduction in mattress turnover time between patients.

- Preliminary data suggested a significant reduction in overall treatment costs associated with pressure injury management.

Case Study 2: Regional Long-Term Care Facility (Home Medical Mattress Application)

A 150-bed long-term care facility struggled with ongoing issues of incontinence management and the associated challenges of maintaining hygiene and preventing skin irritation among its elderly residents. Their non-waterproof mattress solutions frequently became soiled, requiring costly replacement and posing infection risks.

- Intervention: The facility implemented our home medical mattress, specifically the waterproof mattress variant, across all resident rooms. The custom waterproof mattress feature was highly valued for its robust barrier properties and ease of cleaning.

-

Results (Post-Implementation, 6 months):

- A dramatic 95% reduction in mattresses requiring premature replacement due to fluid contamination.

- Noticeable improvement in facility hygiene and reduction in odors.

- Positive feedback from nursing staff regarding the simplified cleaning protocols and reduced time spent on mattress maintenance, freeing up more time for direct patient care.

- Improved resident comfort and skin integrity, attributed to better moisture management and a consistently clean environment.

These cases underscore the tangible benefits of investing in a high-quality medical mattress, demonstrating not just theoretical advantages but measurable improvements in patient safety, staff efficiency, and operational sustainability. Our commitment to excellence in every medical grade mattress we produce translates directly into superior outcomes for healthcare providers and their patients.

Trustworthiness & Support: FAQ, Lead Time, Warranty, and After-Sales

Frequently Asked Questions (FAQ)

- Q: What makes your medical mattress different from a standard mattress?

- A: Our medical mattresses are specifically engineered with multi-layered, medical-grade foams for superior pressure redistribution, reducing the risk of pressure injuries. They feature waterproof, anti-bacterial, and vapor-permeable covers for stringent infection control and enhanced durability, adhering to strict medical device standards (ISO 13485, FDA, CE).

- Q: Are your mattresses suitable for patients at high risk of pressure injuries?

- A: Yes, our Special Supply Medical Mattresses are designed for patients at various risk levels, including high-risk individuals. Their advanced foam constructions and pressure-mapping validated performance ensure optimal pressure relief and shear reduction.

- Q: How do I clean and maintain the waterproof mattress cover?

- A: The covers are designed for easy cleaning. They can be wiped down with common hospital-grade disinfectants. For deeper cleaning, many covers are removable and machine washable at temperatures up to 95°C, ensuring comprehensive decontamination.

- Q: Can these mattresses be used with adjustable hospital beds?

- A: Absolutely. Our medical mattresses are highly flexible and designed to articulate seamlessly with all standard adjustable hospital beds, maintaining their therapeutic properties and structural integrity through various positions.

- Q: Do you offer customization for specific facility needs?

- A: Yes, we specialize in customized solutions, including custom waterproof mattress dimensions, specific foam compositions, and unique cover features to meet the precise requirements of your facility or patient population.

Lead Time and Fulfillment

Our commitment to efficiency ensures timely delivery of your orders. Standard medical mattress models typically have a lead time of 2-4 weeks from order confirmation to shipment, depending on order volume. For custom waterproof mattress solutions or large-scale projects, lead times will be provided upon detailed quotation, factoring in design, production, and testing requirements. We maintain a robust supply chain and optimized manufacturing processes to meet your delivery schedules reliably. Urgent orders can often be accommodated with prior arrangement.

Warranty Commitments

We stand behind the quality and durability of our Special Supply Medical Mattresses with comprehensive warranty coverage:

- Mattress Core: 5-year limited warranty against manufacturing defects and undue compression loss (defined as greater than 20% loss of original height) under normal use and care.

- Mattress Cover: 2-year limited warranty against manufacturing defects, material failure, and zipper malfunction under normal use and recommended cleaning protocols.

Our warranty reflects our confidence in the high-grade materials and meticulous manufacturing processes of every medical mattress we produce.

Customer Support and After-Sales Service

Our dedication to our clients extends far beyond the point of sale. We provide comprehensive after-sales support to ensure maximum operational efficiency and satisfaction with our products:

- Dedicated Support Team: A team of experienced technical professionals is available to address any inquiries regarding product usage, maintenance, or troubleshooting.

- Technical Assistance: We offer guidance on optimal mattress selection for specific patient profiles and clinical needs, as well as support for installation and integration into existing healthcare infrastructure.

- Training & Resources: Educational materials and in-service training sessions can be arranged for your staff on proper mattress care, cleaning protocols, and features to maximize the lifespan and effectiveness of the medical mattress.

- Parts & Service: Availability of replacement parts (e.g., covers) and guidance on service requirements to ensure continuous functionality.

We are committed to building long-term partnerships with our B2B clients, providing reliable products and unparalleled support to enhance patient care and optimize your healthcare operations.

Authoritative References

- National Pressure Ulcer Advisory Panel (NPUAP). (2019). NPUAP Pressure Injury Staging System. Retrieved from https://npiap.com/

- International Organization for Standardization (ISO). (2016). ISO 13485:2016 Medical devices – Quality management systems – Requirements for regulatory purposes. Retrieved from https://www.iso.org/standard/59752.html

- U.S. Food and Drug Administration (FDA). (2023). Medical Devices. Retrieved from https://www.fda.gov/medical-devices

- ASTM International. (2018). ASTM F2328-18, Standard Test Method for Pressure-Distributing Characteristics of Clinical Beds. Retrieved from https://www.astm.org/f2328-18.html

- Centers for Disease Control and Prevention (CDC). (2020). Guidelines for Environmental Infection Control in Healthcare Facilities. Retrieved from https://www.cdc.gov/infectioncontrol/guidelines/environmental/

-

The Truth About "Orthopedic" Mattresses for Sore Back PainNewsAug.23,2025

-

Space-saving Benefits of a Single Mattress CubeNewsAug.23,2025

-

Eco-friendly Advantages of a Silicon MattressNewsAug.23,2025

-

How to Fix Sagging in a Special MattressNewsAug.23,2025

-

How Ambulance Stretcher Mattresses Reduce Pressure InjuriesNewsAug.23,2025

-

Best Cleaning Practices for a Hospital Mattress DoubleNewsAug.22,2025

-

Mattresses Designed for Back Pain ReliefNewsAug.08,2025