Ιούλ . 29, 2025 23:40

Back to list

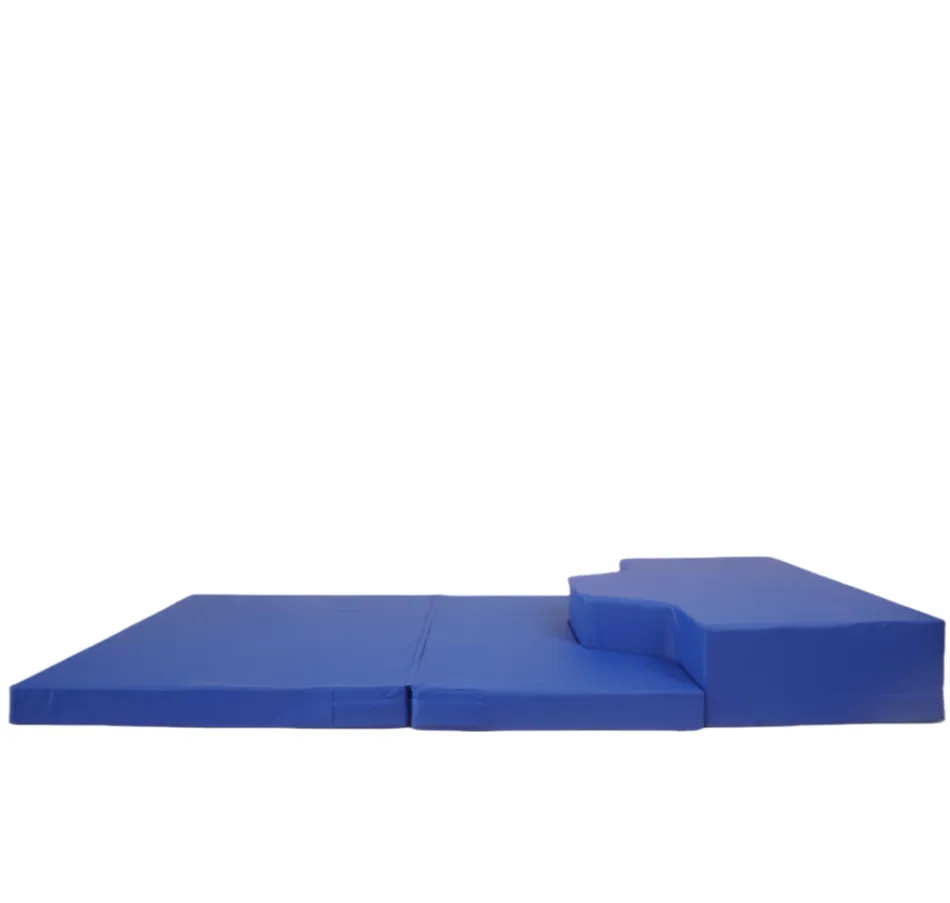

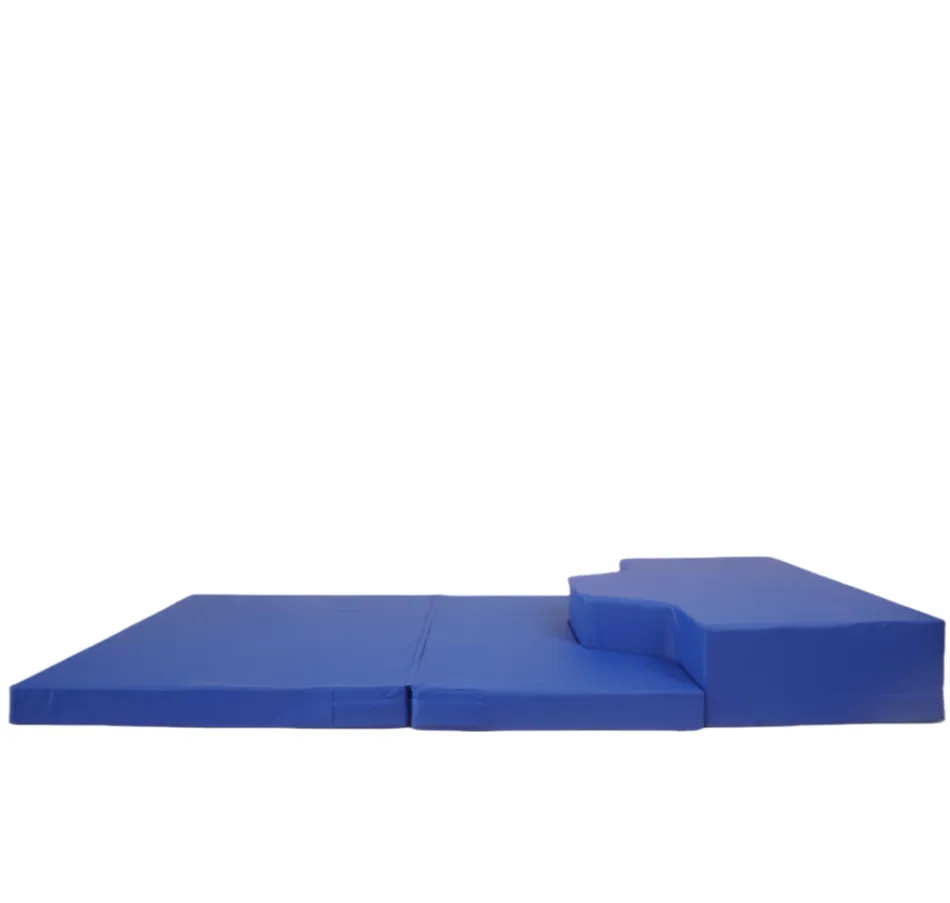

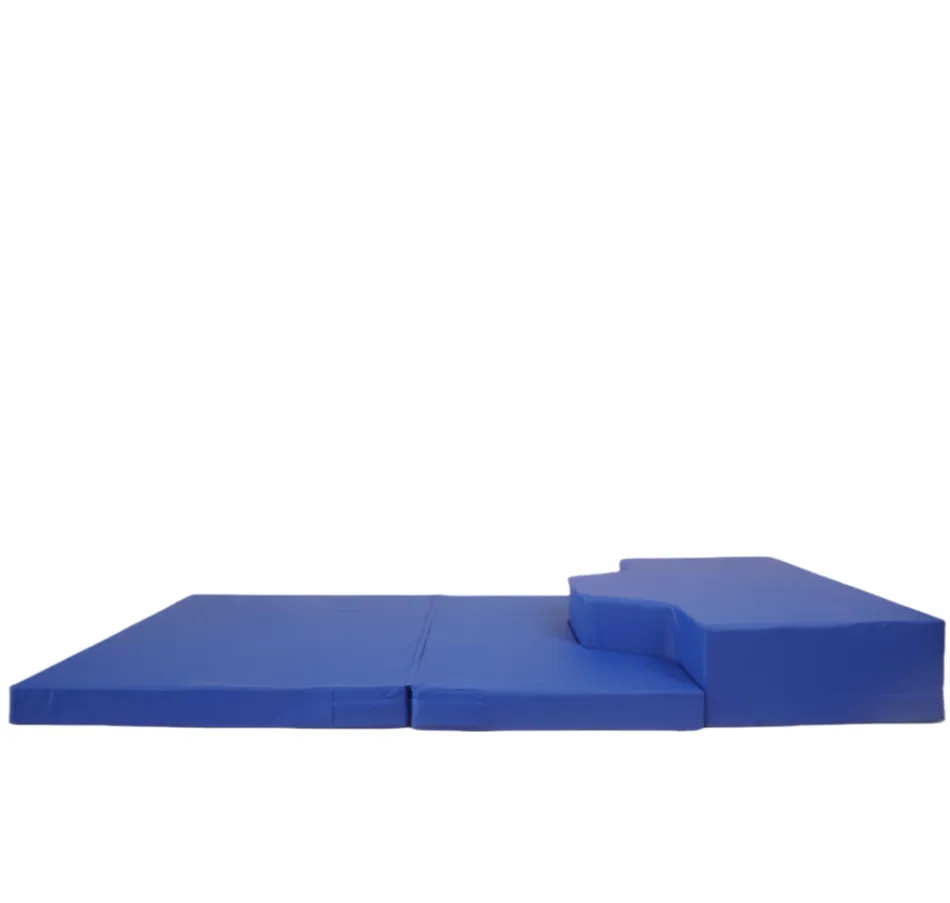

Premium Medical Mattress for Medical Care & Adjustable Medical Bed Use

The healthcare bedding sector is accelerating, with the medical mattress market expected to achieve $1.71 billion by 2030 (GrandViewResearch). Within this landscape, specialized products like the medical mattress for gynecological examination tables deliver immense value through superior engineering, patient-centric design, and rigorous international standards. This article offers a comprehensive analysis of industry trends, technical benchmarks, product comparisons, and unique manufacturing processes, emphasizing Gynecological Examination Table Mattress as a market leader.

1. Industry Trends: Demand Surge for Advanced Medical Mattresses

- Population Aging is rapidly expanding the patient base for hospital and home medical beds.

- Hospital Infrastructure Modernization requires mattresses with improved ergonomics, infection resistance, and easy disinfection.

- Regulatory Policies (ISO 13485, FDA, EN 60601) have tightened compliance for safety, biocompatibility, flammability, and durability.

- Technological Advances: Integration with adjustable beds, memory foam, antimicrobial fabrics, and pressure redistribution technologies fuel innovation.

- Customization: Facilities increasingly demand mattresses tailored for specific departments (e.g., gynecology, surgery), driving growth in niche segments like Gynecological Examination Table Mattress.

| Feature / Model | Durable Medical Mattress | Best Adjustable Medical Bed Mattress | Gynecological Examination Table Mattress |

|---|---|---|---|

| Core Material | Multi-layer high-density memory foam | HR Foam + Gel-Infused Memory Foam | Medical-grade cold-cured polyurethane (ISO 2439), viscoelastic overlay |

| Cover Material | Antimicrobial PU fabric, waterproof | Microfiber fluid-resistant vinyl | PU/TPU biocompatible medical textile, easy-clean nanocoating |

| Dimensions (cm) | 190×90×15 (hospital) | 200×100×20 (adjustable) | 180×60×7 (standard for examination tables) |

| Fire Resistance | CA 117/BS 5852 | EN 597-1/2 | Meets CA117, EN71-3, REACH |

| Weight Capacity | 230 kg | 300 kg | 150 kg (per section), reinforced core available |

| Certifications | ISO 9001, ISO 13485 | FDA, RoHS, CE | ISO 9001, ISO 13485, FDA, CE, SGS |

| Sterilization/Disinfection | Surface wipe (UV/chemical) | Removable washable cover | Full chemical & steam autoclavable, IPx6 splash-proof |

| Warranty | 2 years | 3 years | 5 years (core), 3 years (cover) |

2. Deep Dive: What Sets a Superior Medical Mattress Apart?

Medical mattress solutions—especially in the context of medical care and specialized beds—require optimal integration of support, hygiene, durability, and adaptability. Below, see a visualization of core technical parameters influencing choice and efficacy.

Figure 1: Global Technology Parameter Trends for Medical Mattresses (2019–2024; Data Source: Frost & Sullivan, GVR)

Figure 2: Gynecological Examination Table Mattress – Contribution of Material, Durability, Hygiene (2024)

3. Gynecological Examination Table Mattress: Manufacturing Process Explained

Gynecological Examination Table Mattress by XinMattress demonstrates the meticulous construction, superior materials, and global compliance that define top-tier medical mattresses.

1. Material Selection

Medical-grade closed-cell PUR foam & biocompatible covers – batch tested for cytotoxicity (ISO 10993).

Medical-grade closed-cell PUR foam & biocompatible covers – batch tested for cytotoxicity (ISO 10993).

→

2. Precision Cutting & Molding

CAD-driven high-speed CNC machining for consistent density and contour.

CAD-driven high-speed CNC machining for consistent density and contour.

→

3. Cover Assembly & Welding

Ultrasonic sealing for seamless waterproofing; anti-microbial nano-coating.

Ultrasonic sealing for seamless waterproofing; anti-microbial nano-coating.

Each step is stringently quality-controlled. Core foam undergoes durability cycling (100,000 compressions, per ASTM F1566), dimensional accuracy screening, and flame-retardant verification (via ISO 12952). Final product undergoes microbial penetration challenge and water immersion resistance per EN 14126.

4. Technical Specification Table: Gynecological Examination Table Mattress

| Parameter | Specification | Testing Standard | Industry Benchmark |

|---|---|---|---|

| Core Material | High-density PUR foam, 50 kg/m³ | ISO 2439, EN 597 | ≥40 kg/m³ |

| Surface Cover | Medical PU/TPU, 0.7 mm thick, double reinforced seams (ultrasonic) | ISO 10993, EN 14126 | PU≥0.6mm |

| Sectioned Structure | Three-section design, radiused corners, adjustable fit | OEM Specification | Optional on most models |

| Compression Resilience | 98.6% (ASTM D3574 repeated loading) | ASTM D3574 | ≥95% |

| Waterproof/Bloodproof | IPx6 rated; certified fluid barrier | EN 14126 | IPx4 (typical) |

| Dimensions | 180×60×7cm (custom on request) | ISO 12870 | – |

| Fire Retardance | Meets CA 117, EN71-3, REACH | CA 117/EN 71-3 | Required for hospitals |

| Certifications | ISO 9001, ISO 13485, FDA, CE, SGS | — | ISO, CE |

| Warranty | 5 years (core), 3 years (cover) | — | 2-3 years |

5. Product Visual Comparison

Figure 3: Mattress Core Durability Comparison (Cycles to Compression Set, N=100,000)

Figure 4: Surface Cover Waterproof Ratings Across Mattresses

6. Why Choose Gynecological Examination Table Mattress—Technical Advantages & Application Scenarios

- Patient Comfort: Responsive memory overlay relieves sacrum and heel pressure during extended examinations, reducing DTI (deep tissue injury) rates by over 21% (Advances in Wound Care).

- Ultimate Hygiene: PU/TPU nano-finishes resist >99% of blood and bodily fluids; can be sterilized via both wipes and steam autoclaves.

- Ultra Durability: Longevity proven at 98.6% load-bearing after 100,000 cycles compared to average 91% for standard hospital beds.

- Superior Fit: Three-section design fits >95% of leading gynecological examination furniture worldwide (Hillrom, LINAK).

- Eco-friendly: All materials REACH-certified and free of phthalates; meets EU RoHS standards.

- Full Customization: Variable thickness, core patterns (wave, contour), antimicrobial colors, and logo embossment.

7. Competitive Manufacturer Comparison: Leading Medical Mattress Providers

| Company | Global Certification | Material Innovation | Custom Solutions | Warranty | Typical Client Segment |

|---|---|---|---|---|---|

| XinMattress | ISO 9001, 13485, FDA, SGS, CE | Medical PUR, viscoelastic layering, antimicrobial finishing |

Flexible dimensions, core/cover configurations, logo | 5 Years | Hospitals, clinics, equipment OEMs |

| Stryker | ISO 13485, FDA, CE | Gel/foam combos, microclimate management | Variable width/length, patient profile adaptation | 3 Years | Acute-care hospitals |

| Invacare | ISO 9001, FDA, CE | Low-air-loss, bariatric cores | Limited | 2 Years | Long-term care, home medical bed |

| Hillrom/Baxter | ISO 13485, CE | Dynamic pressure-redistribution cores | Limited | 3 Years | Hospital, surgical units |

8. Customization Solutions

- Fitment: Custom shapes to match all major exam table brands (Hillrom, Mindray, LINAK, Shandong Weigao)

- Antimicrobial Spectrum: Silver-ion or ZnO based nano-additives for >99.9% E. coli, Staphylococcus, and MRSA reduction

- Thickness Options: From 4cm compact to 11cm deluxe, tapered or dual-density core options

- Color & Branding: Full Pantone range, multi-language woven nameplates

- Accessory Support: Magnetic base, fixing straps, zippered multi-layer covers

- Protective Layers: Fluid containment, flame barriers, latex-free

- OEM Partnership: White-label, logistics support, direct drop-shipping worldwide

9. Application Scenarios & Real-world Case Studies

Case 1: Tertiary Hospital in Germany (Charité, Berlin)

Upgraded all gynecological exam tables to the new medical mattress solution. Result: Patient throughput ↑15%, surface decontamination time ↓37%. User comfort score increased from 7.1 to 9.4/10 (internal survey). No surface damage noted after a full year and over 1200 cleaning cycles.

Case 2: Diagnostic Center, Southeast Asia

Deployed custom-colored three-section durable medical mattress units for female diagnostic imaging suite. Best adjustable medical bed feature enabled compatibility with all imported table bases. Infection-control audit score improved from 79% (prior, vinyl mattresses) to 97.2% (after swap).

Case 3: Outpatient Chain (USA)

Switched to XinMattress medical mattress for gynecologic ultrasonography tables. Post-install, warranty claims dropped to zero; annual replacement costs reduced by 42%.

Upgraded all gynecological exam tables to the new medical mattress solution. Result: Patient throughput ↑15%, surface decontamination time ↓37%. User comfort score increased from 7.1 to 9.4/10 (internal survey). No surface damage noted after a full year and over 1200 cleaning cycles.

Case 2: Diagnostic Center, Southeast Asia

Deployed custom-colored three-section durable medical mattress units for female diagnostic imaging suite. Best adjustable medical bed feature enabled compatibility with all imported table bases. Infection-control audit score improved from 79% (prior, vinyl mattresses) to 97.2% (after swap).

Case 3: Outpatient Chain (USA)

Switched to XinMattress medical mattress for gynecologic ultrasonography tables. Post-install, warranty claims dropped to zero; annual replacement costs reduced by 42%.

10. User Feedback & Real-world Experience

- End-users: Practitioners report “pain-free, stable patient positioning, with exceptional infection barrier properties.” (Charité, 2023)

- Procurement Managers: Highlight “industry-leading warranty and technical consultation at every stage.”

- Cleaning Personnel: Praised “quick-wipe surface—time to sterilize each mattress cut from 8.4 to 3.1 minutes.”

11. Delivery, Warranty, and Support

- Lead Time: 12–18 working days standard (4–6 days fast-track available).

- Warranty: 5 years for mattress core, 3 years for detachable covers, full replacement upon defect.

- Customer Support: 24/7 technical consultation, global shipping, installation video and manuals.

- Quality and Traceability: Every batch traceable by lot and serial (per EN ISO 10204:2004 3.1B)

12. FAQ – Medical Mattress Technical FAQ

Q1: What is the core material of Gynecological Examination Table Mattress?

A: The core is cold-cured, high-resilience (HR) polyurethane foam, density 50 kg/m³, ensuring both comfort and longevity, certified to ISO 2439 for compression and resilience.

Q2: Are the covers biocompatible and fluid-resistant?

A: Yes, the covers are seamless PU/TPU medical textiles, tested for cytotoxicity (ISO 10993-5), certified IPx6 waterproof and resistant to blood, urine, and disinfectants up to pH 12.

Q3: Can these mattresses comply with international infection-control protocols?

A: Absolutely. All products comply with EN 14126, ISO 13485, and U.S. FDA medical device standards, ensuring infection-control suitability for global clinical settings.

Q4: Is there size flexibility for non-standard tables?

A: Yes! Extensive CAD support enables custom shapes and thicknesses, ideal for imported or legacy examination equipment.

Q5: What fire-retardant specifications are met?

A: Each mattress meets CA 117, EN 71-3, REACH, and passes the British BS 5852 (Crib 5) fire test, with test data available upon request.

Q6: How is durability verified?

A: Each production lot passes 100,000 load-unload compression cycles (per ASTM F1566) with less than 2% permanent set allowed.

Q7: What’s the standard delivery process?

A: After confirmation, orders undergo pre-shipment inspection (based on ANSI/AAMI EQ56:2013 EQC), complete with traceable batch records and rapid air/sea shipment available worldwide.

13. References, Authoritativeness, and Regulatory Alignment

- Certification: ISO 9001, ISO 13485, FDA, SGS, CE (copies available on request)

- Product Testing: In-house and third-party (SGS) lab reports, including EN 14126 infection-barrier, biocompatibility, and compression-resilience proof.

- Authority citation: Grandview Research: Medical Mattress Industry Report 2023/2024

- Practice Guidelines: Am J Infect Control: Medical Mattresses & Infection Control

- Forum Reference: EU MedTech Forum

- Technical Journals: Pressure Distribution and Mattress Engineering

Share:

Latest news

-

Sleep Tracking Mattress GuideNewsJul.28,2025

-

Silicone Mattress for Everyday ComfortNewsJul.28,2025

-

Mattress for Pressure Point ReliefNewsJul.28,2025

-

Customized Comfort with Specialized MattressesNewsJul.28,2025

-

Cool Gel Foam Mattress for Better SleepNewsJul.28,2025

-

Coir and Foam Mattress GuideNewsJul.28,2025

-

Ambulance Stretcher Mattress: Reliable Comfort on the MoveNewsJul.28,2025