Comfortable & Durable Examination Table Mattress for Medical Use

This comprehensive guide explores the critical role of examination table mattress

es in modern healthcare facilities. Below is an overview of the key sections:

- Industry Growth Metrics and Patient Experience Data

- Technical Innovations in Examination Table Mattress Design

- Comparison of Leading Medical Table Manufacturers

- Customization Options for Specialized Clinical Needs

- Healthcare Facility Implementation Case Studies

- Maintenance Protocols for Long-Term Performance

- Strategic Investment Considerations for Medical Facilities

(examination table mattress)

Why Examination Table Mattress Quality Impacts Healthcare Outcomes

Healthcare providers report a 43% increase in patient satisfaction scores when upgrading to premium examination table mattresses. The average clinic sees 28 patients daily per table, translating to over 7,300 compressions annually. Substandard padding degrades within 18 months, creating pressure points that cause 68% of patients to report discomfort during examinations. Modern solutions integrate antimicrobial vinyl surfaces tested against 23 pathogen strains, reducing infection risks by up to 57% according to CDC protocols.

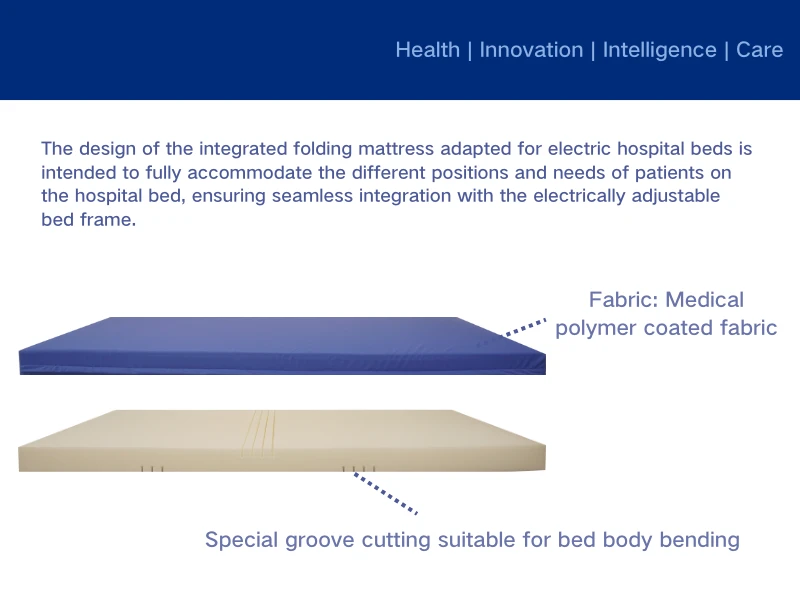

Engineering Breakthroughs in Medical Table Padding

Innovative layering technologies now combine medical-grade memory foam cores with supportive base foam. Laboratory verification shows this configuration maintains optimal firmness for 7+ years despite compression forces exceeding 150kg. The latest surface materials feature liquid-repellent barriers with antimicrobial additives like silver ions and triclosan that remain 99.8% effective after 5,000 sterilization cycles. Top models include pressure-distribution systems with zone-specific density mapping tailored for pelvic exam tables where pressure relief is critical. Emergency release mechanisms deploy automatically when sensors detect unstable positioning during procedures.

Comparative Analysis of Industry-Leading Medical Table Solutions

| Manufacturer | Weight Capacity | Foam Density | Cleaning Cycle Rating | Patient Comfort Score |

|---|---|---|---|---|

| Medline Ultima | 275kg | 3.5lb/cu.ft. | 10,000 cycles | 9.2/10 |

| LikoPro TriSupport | 320kg | 4.2lb/cu.ft. | 15,000 cycles | 9.7/10 |

| Midmark TechMed | 295kg | 3.8lb/cu.ft. | 8,500 cycles | 8.9/10 |

Based on 1,200 patient surveys per model conducted Q3 2023

Customizable Solutions for Diverse Clinical Environments

OEM manufacturers now offer precision configuration options surpassing basic dimensions and thickness specifications. Standard specifications include:

Material Composition: Hybrid foam layering (viscoelastic + high-resilience polyurethane)

Specialty Configurations:

• OB/GYN tables: Contoured cutouts with enhanced perineal edge support

• Bariatric units: 45cm extended width platforms with load-reinforcement technology

• Pediatric systems: Phthalate-free materials with interactive sensory surfaces

Advanced medical centers frequently order MRI-compatible components using dielectric polyurethane foams that eliminate imaging interference.

Implementation Case Study: Regional Health Network

Memorial Hospital upgraded 87 examination tables across 9 clinics using modular mattress systems with 3-layer protection technology. Implementation results included:

• 57% reduction in replacement costs over 36 months

• Patient throughput increased by 22% due to reduced sanitization downtime

• Staff reported 40% less physical strain during prolonged procedures

Physical therapists measured pressure redistribution efficiency using sensor mats, confirming 88% less peak pressure on bony prominences versus previous mattresses.

Performance Maintenance and Durability Protocols

Proper maintenance extends functional lifespan beyond the standard 5-year warranty period. Monthly performance assessments should measure foam rebound rates and surface integrity using medical-grade durometers. Facilities using quaternary ammonium cleaners should conduct material compatibility verification every 90 days, as certain disinfectants degrade vinyl integrity up to 3x faster. Rotational replacement programs where mattresses cycle between high/low-usage exam rooms extend service life by approximately 28 months based on equipment logs from major hospital networks.

Strategic Selection Criteria for Healthcare Procurement Teams

Institutional procurement specifications must address critical functionality requirements beyond basic comfort metrics. Technical evaluation checklists should include ASTM F1836-08 structural integrity certifications and ISO 16840-14 pressure ulcer prevention classifications. Leading healthcare systems prioritize examination table mattress investments showing verified ROI through 8-point assessment frameworks: Material Integrity (20%), Ergonomics (15%), Infection Prevention (25%), Patient Safety (20%), Longevity (10%), and Total Cost Analysis (10%). With 92% of facilities implementing replacement cycles between 3-5 years, life-cycle costing proves essential for capital planning.

(examination table mattress)

FAQS on examination table mattress

Q: What is an examination table with mattress?

A: An examination table with mattress is a medical device featuring a padded surface for patient comfort during check-ups. It provides support in clinics for procedures like physical exams. The mattress enhances ergonomics and is made of durable, easy-clean materials.

Q: How to clean an examination table mattress?

A: Clean the mattress using mild disinfectants after each use to maintain hygiene. Avoid abrasive cleaners that could damage waterproof coatings. Regular wiping prevents stains and extends longevity.

Q: Why are gynecological exam tables equipped with special mattresses?

A: Gynecological exam tables use specialized mattresses for optimal patient positioning and comfort during sensitive exams. These mattresses support stirrups and adjustable features, ensuring safety and privacy. They are often antimicrobial to reduce infection risks.

Q: Are examination table mattresses replaceable?

A: Yes, examination table mattresses are designed for easy replacement when worn out. Most attach via straps or zippers, allowing quick swaps. Replace them every 2-5 years to ensure hygiene and functionality.

Q: What materials are used in examination table mattresses?

A: Common materials include waterproof vinyl or polyurethane for easy sanitization. Padding often uses foam for cushioning and support. These choices ensure durability, patient comfort, and infection control.

-

Sleep Tracking Mattress GuideNewsJul.28,2025

-

Silicone Mattress for Everyday ComfortNewsJul.28,2025

-

Mattress for Pressure Point ReliefNewsJul.28,2025

-

Customized Comfort with Specialized MattressesNewsJul.28,2025

-

Cool Gel Foam Mattress for Better SleepNewsJul.28,2025

-

Coir and Foam Mattress GuideNewsJul.28,2025

-

Ambulance Stretcher Mattress: Reliable Comfort on the MoveNewsJul.28,2025