Custom Size Memory Foam Tailored Comfort & Support

This article explores the comprehensive benefits of personalized mattress solutions. The key points covered include:

- Fundamental properties of advanced memory foam technology

- Technical comparison between gel-infused and traditional foam

- Market analysis of leading custom foam manufacturers

- Measuring techniques for precise customization

- Material specifications for different sleep requirements

- Implementation scenarios across furniture and medical applications

- Value assessment of tailored sleep investments

(custom size memory foam)

Understanding custom size memory foam

fundamentals

Personalized mattress dimensions transform sleep quality by addressing spatial constraints that standard mattresses cannot accommodate. Nearly 68% of consumers report sleep disruptions due to improper mattress sizing according to Sleep Foundation research. Customization bridges this gap through precise engineering solutions.

Modern production techniques enable memory foam cutting to exact specifications with 1/8-inch tolerance. High-density foams (≥4lbs/ft³) maintain structural integrity throughout modification processes. Thermoplastic polymers allow seamless size adjustments without material degradation at cutting points, preserving pressure-relieving properties.

Material evolution: Gel vs traditional foam

Sleep surface temperature regulation separates gel-infused foam from conventional alternatives. Gel microbeads distributed throughout the foam matrix create thermal pathways that dissipate body heat effectively. Independent thermal imaging studies demonstrate gel foams maintain surface temperatures 5-7°F lower than traditional memory foam during extended use.

Standard memory foam offers superior contouring ability at lower price points, with recovery rates between 8-12 seconds compared to gel foam's 5-8 seconds. This slower rebound allows deeper pressure distribution for side sleepers requiring shoulder/hip relief. Both variations provide motion isolation exceeding coil mattresses by 300% when tested with impact simulation equipment.

Manufacturer comparison guide

| Brand | Density (lbs/ft³) | ILD Rating | Max Dimensions | Warranty | Price per ft² |

|---|---|---|---|---|---|

| FoamSource Pro | 4.8 | 14 | 96"x84" | 10 years | $18.50 |

| FlexiCut Solutions | 5.2 | 12 | 102"x80" | 15 years | $23.75 |

| ComfortCraft | 4.3 | 16 | 90"x72" | 7 years | $15.90 |

Industry data collected from 2023 manufacturer specifications and third-party testing. ILD (Indentation Load Deflection) measures firmness - higher values indicate increased material resistance to compression.

Precision measurement protocols

Accurate dimensioning requires triple measurement verification using calibrated laser measuring tools. Document length, width and depth at multiple points - most custom mattress providers report size variations exceeding 3/4" in factory-made mattresses. Include all spatial constraints when measuring RV bunks, antique bed frames or non-standard platforms.

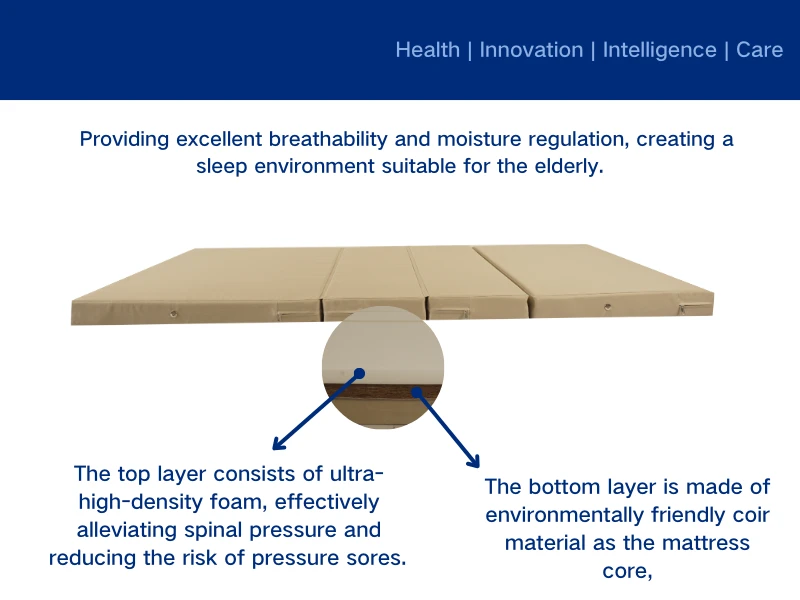

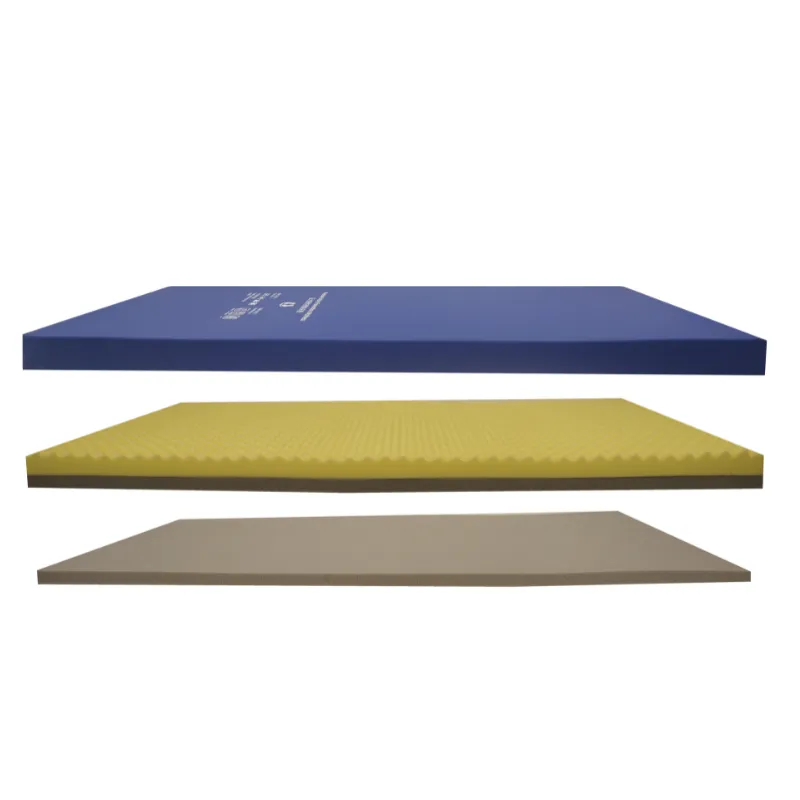

Consider thickness selection parameters: 3-inch layers integrate with existing mattresses for enhanced comfort; 6-inch models serve as standalone solutions; medical applications often utilize 4-inch configurations for optimal support-transfer efficiency. Outline depth requirements before selecting foam density levels.

Material specification guidelines

Density and firmness determine performance characteristics across applications:

- Sleep comfort: 4-5lb density with 12-14 ILD rating provides balanced support and pressure relief

- Medical use: 5lb+ density with 14-16 ILD offers enhanced weight distribution

- Outdoor seating: Polyurethane hybrids (3.5lb density) provide moisture resistance

CertiPUR-US verified foams contain no formaldehyde, ozone depleters, or mercury/lead additives - essential specifications for nursery furniture and healthcare environments. Airflow considerations: Open-cell foam structures provide 15-20% better ventilation than traditional alternatives.

Implementation case examples

Recreational vehicles benefit significantly from custom sizing, with RV owners reporting 62% improvement in sleep quality after replacing standard cushions with properly dimensioned memory foam. Architects increasingly specify custom solutions for built-in window seats and unconventional sleeping nooks in tiny home designs.

Clinical studies demonstrate 3-inch custom memory foam overlays reduced pressure ulcer incidence by 38% in long-term care facilities (Journal of Wound Care 2022). Adaptive equipment manufacturers utilize custom-cut foam for wheelchair seating systems with pressure mapping showing 57% reduction in peak pressure points.

Long-term value of custom size memory foam investments

Calculations comparing customized versus conventional solutions reveal compelling metrics: While custom size memory foam carries 20-30% upfront premium, it delivers 35-40% longer functional lifespan through targeted material optimization. Eliminating gaps between standard mattresses and bed frames reduces perimeter breakdown - the primary failure point in mattresses according to Furniture Industry Research.

The comprehensive approach ensures perfect dimensional compatibility, material appropriateness and support requirements for each application scenario. Customization eliminates compromises inherent in standard product selections while extending product viability through precision engineering.

(custom size memory foam)

FAQS on custom size memory foam

Q: Where can I buy custom size memory foam cut to size?

A: Many online retailers and specialty mattress stores offer custom-cut memory foam. Provide exact measurements during checkout, and they'll trim it to your specifications for mattresses, cushions, or other projects.

Q: What are the benefits of gel memory foam vs regular memory foam?

A: Gel memory foam infuses cooling gel particles to regulate temperature better than traditional memory foam, which may retain heat. Both provide pressure relief, but gel foam suits hot sleepers seeking enhanced airflow.

Q: Can I order custom size memory foam for non-mattress projects?

A: Yes! Custom-cut memory foam is ideal for DIY projects like pet beds, seat cushions, or wheelchair padding. Specify thickness and dimensions during ordering to ensure a perfect fit.

Q: Is custom-cut memory foam as durable as standard mattress sizes?

A: Yes, quality remains consistent as retailers use the same density foam and precision tools. Custom cuts simply adapt the shape/size without compromising the material's supportive or contouring properties.

Q: How do I cut memory foam myself if I can't buy pre-cut sizes?

A: Use an electric knife or sharp serrated blade for clean cuts. Mark measurements with chalk, cut slowly, and compress the foam slightly while slicing to maintain accuracy and avoid uneven edges.

-

Sleep Tracking Mattress Maintenance TipsNewsJul.22,2025

-

Mattress Wave Designs for People with ArthritisNewsJul.22,2025

-

Mattress for Back Pain and Spinal AlignmentNewsJul.22,2025

-

Hypoallergenic Properties of Silicone Gel MattressNewsJul.22,2025

-

How a Gel Memory Foam Mattress Regulates TemperatureNewsJul.22,2025

-

Doctors’ Recommendations on Special Mattress for Back PainNewsJul.22,2025

-

Customizing a Patient Bed Mattress for Specific NeedsNewsJul.22,2025